Heat exchange type reactor core melt trapping device in U-shaped pipe

A core melt and internal heat exchange technology, which is applied to emergency protection devices, reactors, and reduction of greenhouse gases, etc., to achieve the effects of improving utilization, fast and efficient cooling, and occupying limited space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

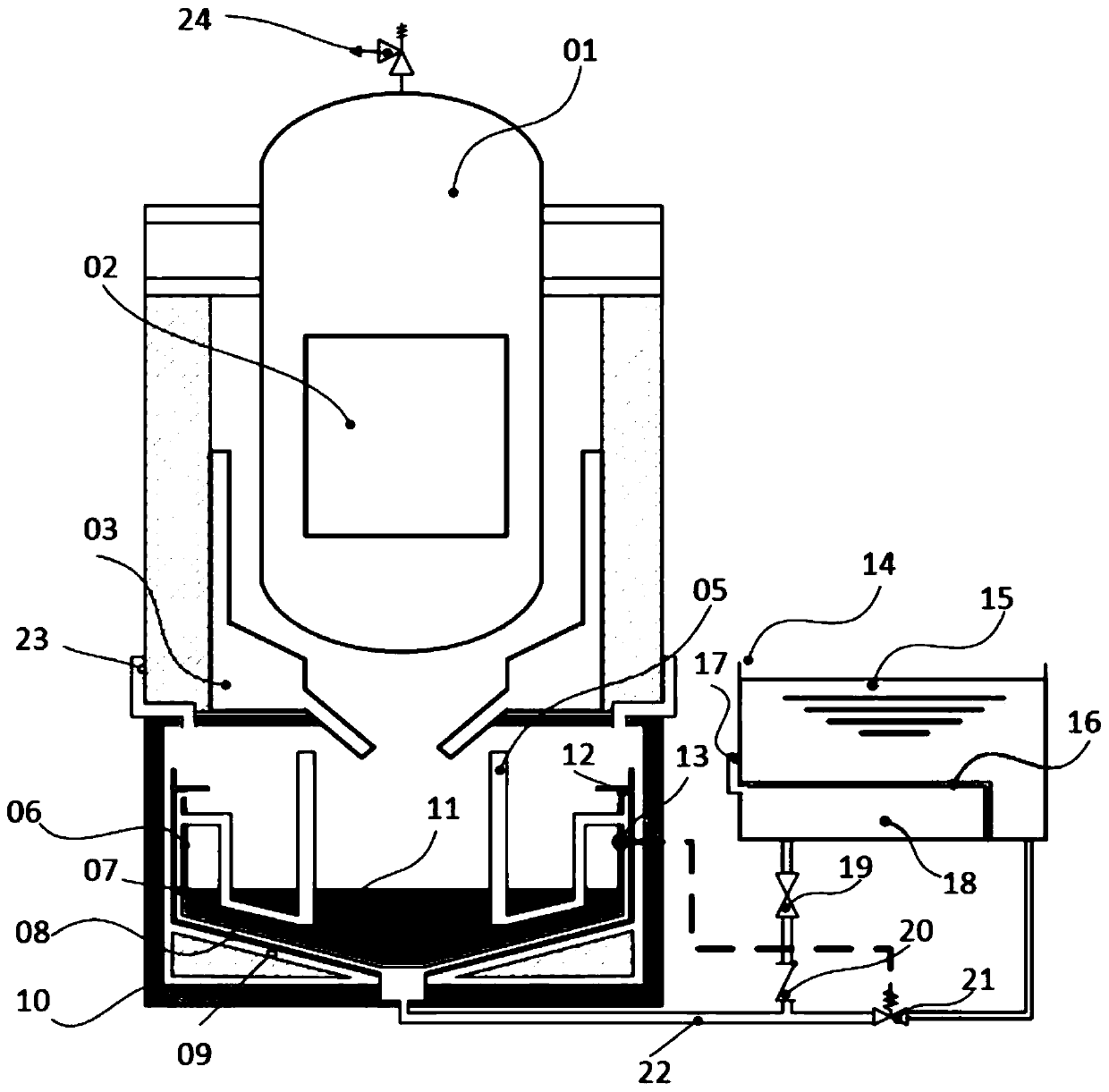

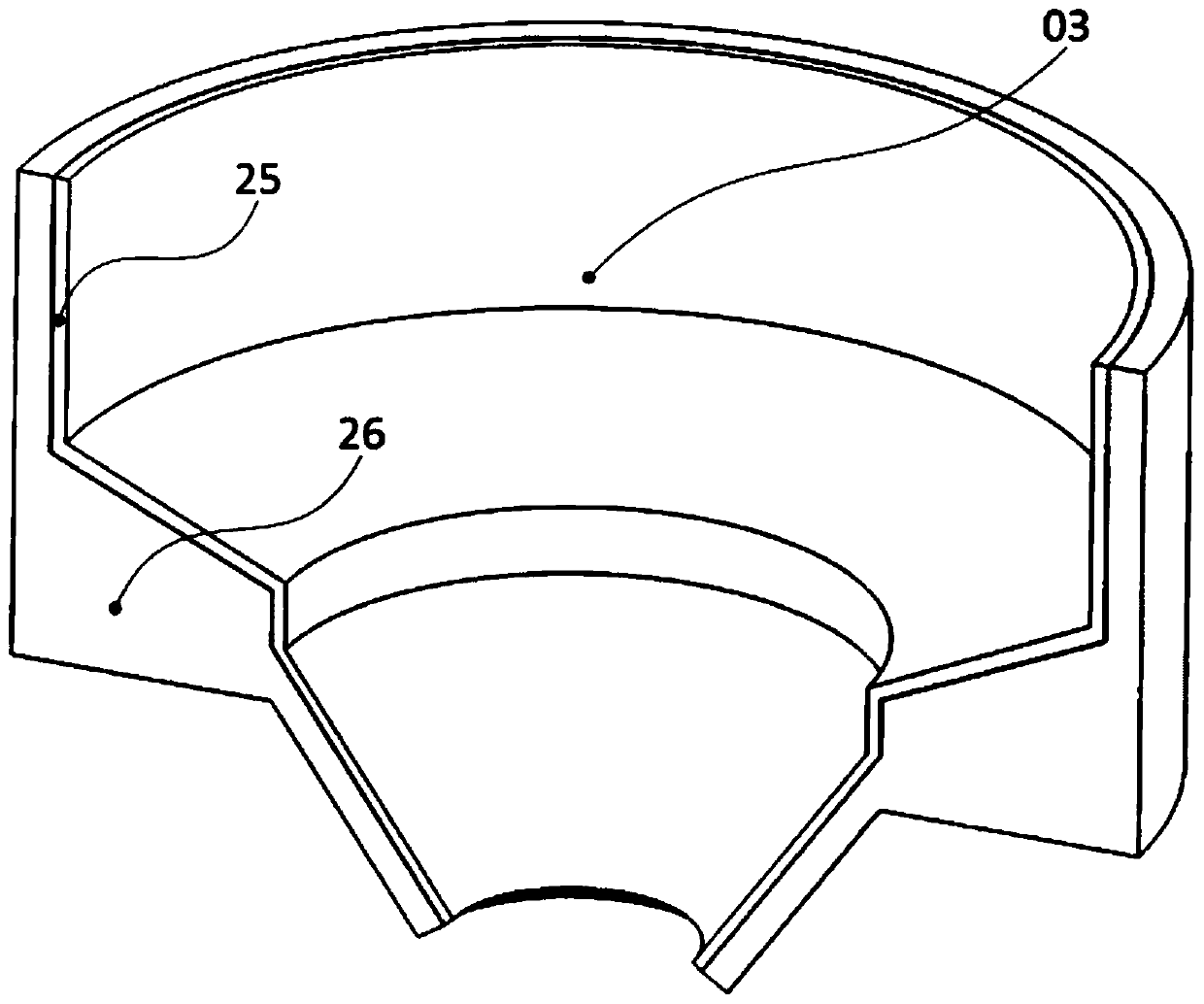

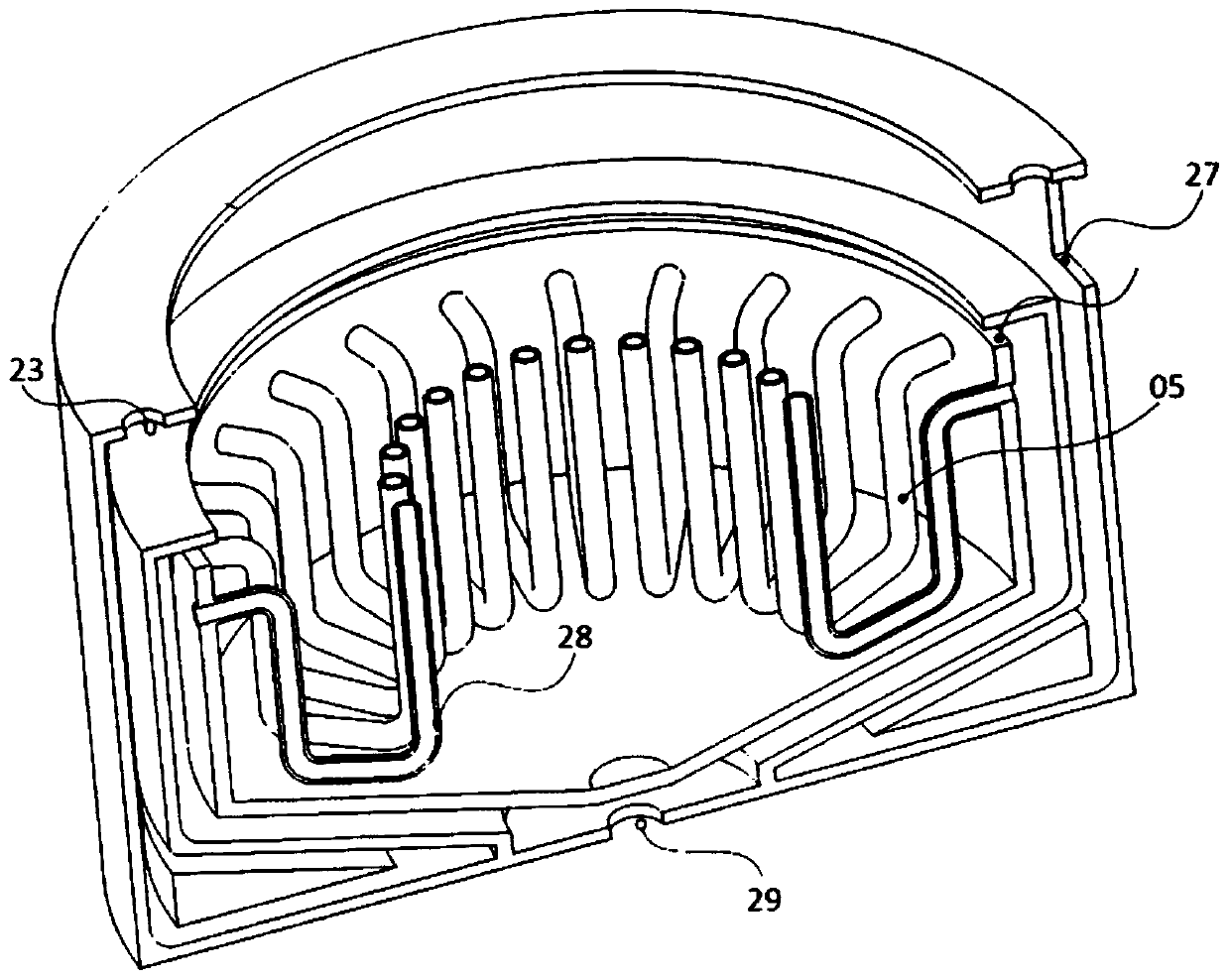

[0037] like figure 1As shown, the present invention provides a U-shaped tube internal heat exchange core melt collection device, including a melt collection and guiding device 03, a crucible retention container 06, a cooling tube bundle, a multi-wall cooling system, and a cooling water injection system and a steam discharge system; the melt collecting and guiding device 03 is arranged on the vertical support inner wall below the reactor pressure vessel 01, which is inclined to the opposite surface of the lower head of the pressure vessel 01 and provided with a stand, and the coaming is drawn toward the center; The crucible retention container 06 is arranged below the melt collecting and guiding device 03; the cooling tube bundle is arranged inside the crucible retention container 06; Relatively fixed and jointly build a cooling channel with the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com