Deep ultraviolet light-emitting element and preparation method thereof

A light-emitting element, deep ultraviolet technology, applied in electrical components, chemical instruments and methods, semiconductor devices, etc., can solve the problems of aging light attenuation, large concentration difference, uneven distribution, etc., to improve luminous efficiency and intensity, reduce aging Light attenuation, effects that improve consistency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

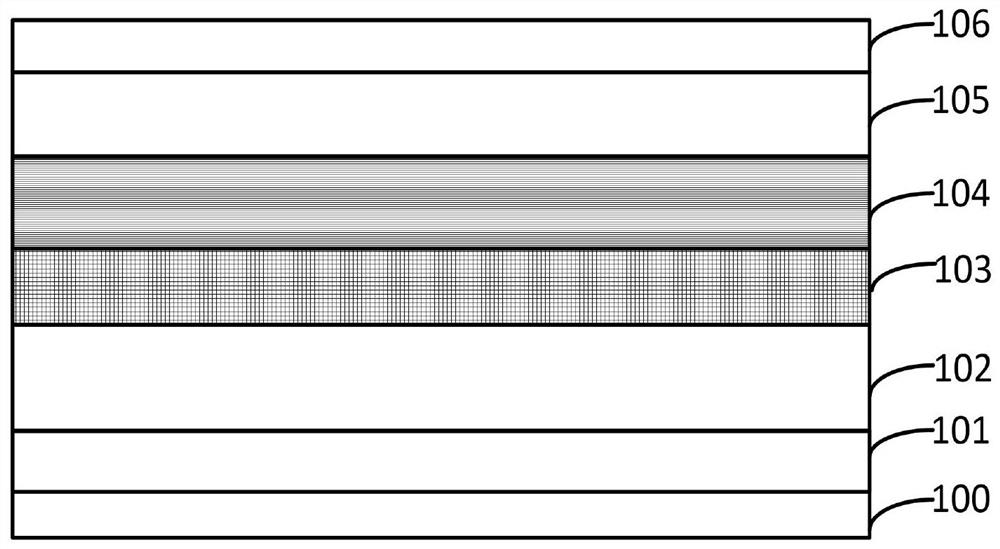

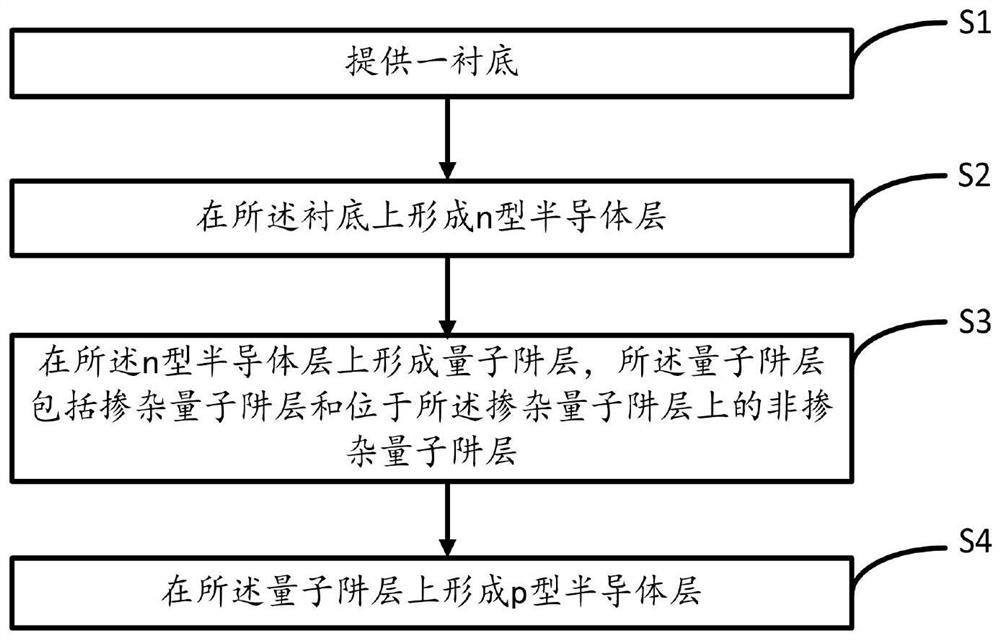

[0055] The quantum well layer of the existing deep ultraviolet light-emitting element is a single-group quantum well structure. Due to the different doping and ionization efficiency of electrons and holes in the deep ultraviolet light-emitting element, the distribution of electrons and holes in the quantum well layer is extremely polar. Non-uniform, and the concentration difference is large, and this phenomenon is more serious with the increase of Al composition in the p-type semiconductor layer, and the large concentration difference and non-uniform distribution of electrons and holes in the deep ultraviolet light-emitting element lead to its general luminous efficiency. Important reasons for less than 5%. In addition, the distance between the Si-doped layer of the quantum well layer and the Mg-doped layer of the p-type semiconductor layer is too close, which will easily lead to element migration and diffusion of Mg and Si under high temperature or long-term use, resulting in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com