Aggregate crusher for cement base material processing

A technology of aggregate pulverizer and cement base material, applied in application, cocoa, grain processing and other directions, can solve the problems of waste time and low pulverization efficiency of cement base material, improve pulverization efficiency, ensure pulverization effect, and speed up pulverization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

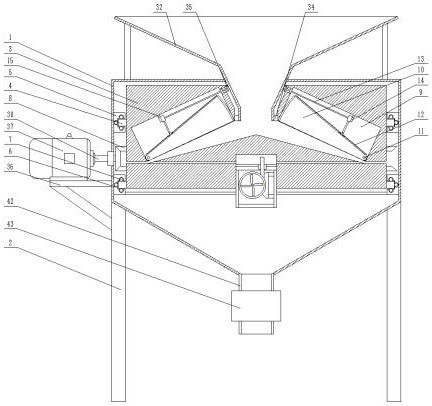

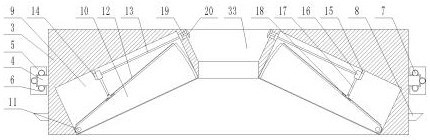

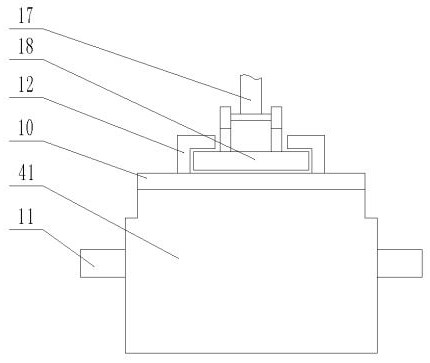

[0030] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7 shown.

[0031] In this device, the device is powered by being connected to an external power supply, and the external power supply is electrically connected to the circulation fan 28 and the low-speed drive motor 37 through a control switch to supply power, thereby controlling the operation of the entire device.

[0032] The creative point of this scheme lies in the structural design of the automatic crushing and crushing upper grinding disc device, combined with the attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4, the automatic extrusion crushing type upper grinding disc device includes an upper grinding disc 3 at the upper center of the inner part of the box body 1, a tapered feeding port 33 is opened at the center of the upper surface of the upper grinding disc 3, and an annular sliding ring is installed at the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com