Red fluorescent powder capable of being excited by blue light and preparation method thereof

A technology of red phosphor and blue light excitation, which is applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve the problems of red phosphor luminous efficiency and unsatisfactory stability, and achieve improved LED lighting efficiency and stable structure , Improve the effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh raw material SrCO 3 2.0 mmol, La 2 o 3 1.0mmol, Sc 2 o 3 1.0mmol, Eu 2 o 3 0.02mmol, after the above raw materials are fully mixed, placed in a high-temperature tube furnace, in 10% H 2 -90%N 2 In the atmosphere, keep warm at 500°C for 6h, heat up to 1400°C for sintering for 4h, continue to heat up to 1500°C for 6h, then cool down to room temperature and take it out. The phosphor powder with uneven luminescence on the surface layer was scraped off, and then the phosphor powder on the inner layer was ground into powder to obtain the red phosphor powder of this embodiment.

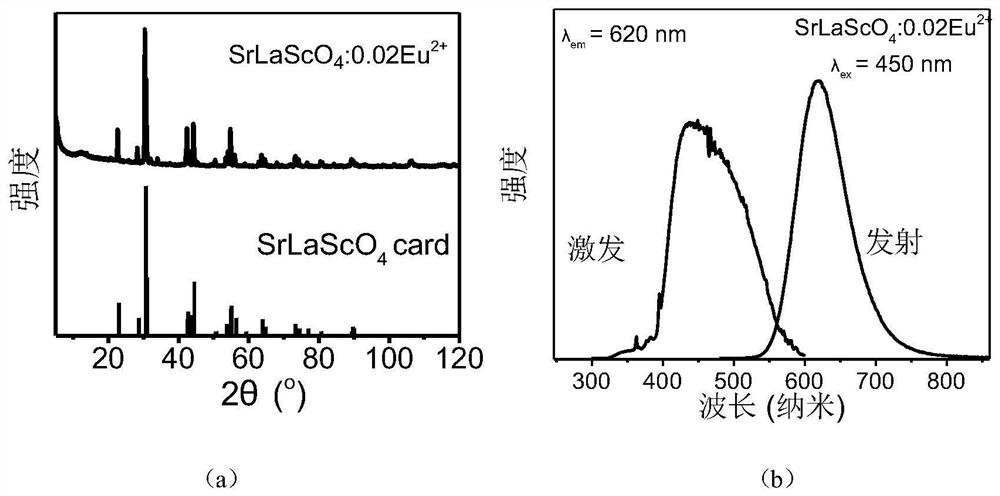

[0043] The phase diagram of the red fluorescent powder described in this embodiment is as attached figure 1 Shown in (a), the fluorescent powder of the present invention corresponds completely to the standard card; Its excitation and emission spectra are as attached figure 1 As shown in (b), the excitation spectrum of the sample is monitored with a wavelength of 620nm. Obviously, the...

Embodiment 2

[0045] Weigh raw material SrCO 3 2.0 mmol, La 2 o 3 1.0mmol, Sc 2 o 3 1.0mmol, Eu 2 o 3 0.1mmol, after fully mixing the above raw materials, put them in a high-temperature tube furnace, in 10% H 2 -90%N 2 In the atmosphere, keep warm at 500°C for 6h, heat up to 1400°C for sintering for 4h, continue to heat up to 1500°C for 6h, then cool down to room temperature and take it out. The phosphor powder with uneven luminescence on the surface layer was scraped off, and then the phosphor powder on the inner layer was ground into powder to obtain the red phosphor powder of this embodiment.

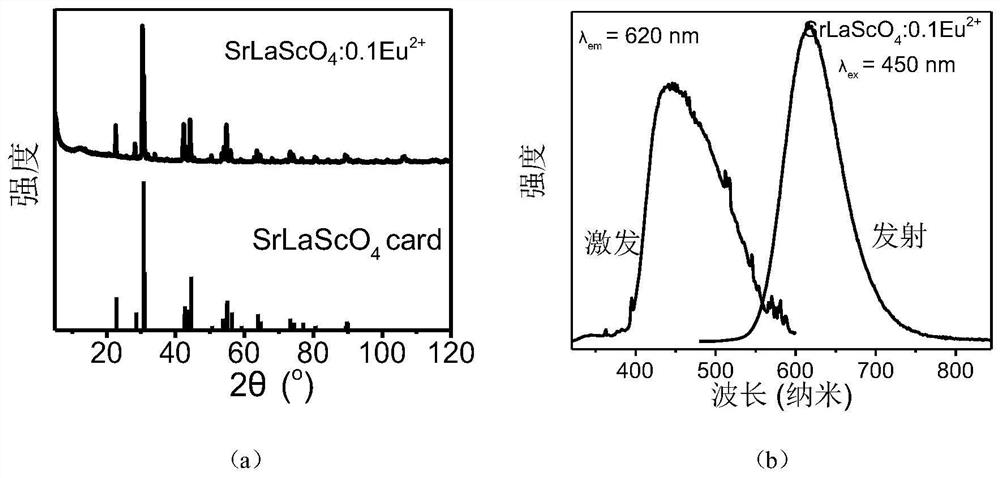

[0046] The phase diagram of the red fluorescent powder described in this embodiment is as attached figure 2 Shown in (a), the fluorescent powder of the present invention corresponds completely to the standard card, and no heterogeneous diffraction peaks are produced; its excitation and emission spectra are as attached figure 2 As shown in (b), the excitation spectrum of the sample is...

Embodiment 3

[0048] Weigh raw material SrCO 3 2.0 mmol, La 2 o 3 1.0mmol, Sc 2 o 3 1.0mmol, Eu 2 o 3 0.1mmol, and take by weighing the additive (NH 4 ) 2 SO 4 , after fully mixing the raw materials and additives, put them in a high-temperature tube furnace, in 10% H 2 -90%N 2 In the atmosphere, keep warm at 500°C for 6h, heat up to 1400°C for sintering for 4h, continue to heat up to 1500°C for 6h, then cool down to room temperature and take it out. The phosphor powder with uneven luminescence on the surface layer was scraped off, and then the phosphor powder on the inner layer was ground into powder to obtain the red phosphor powder of this embodiment.

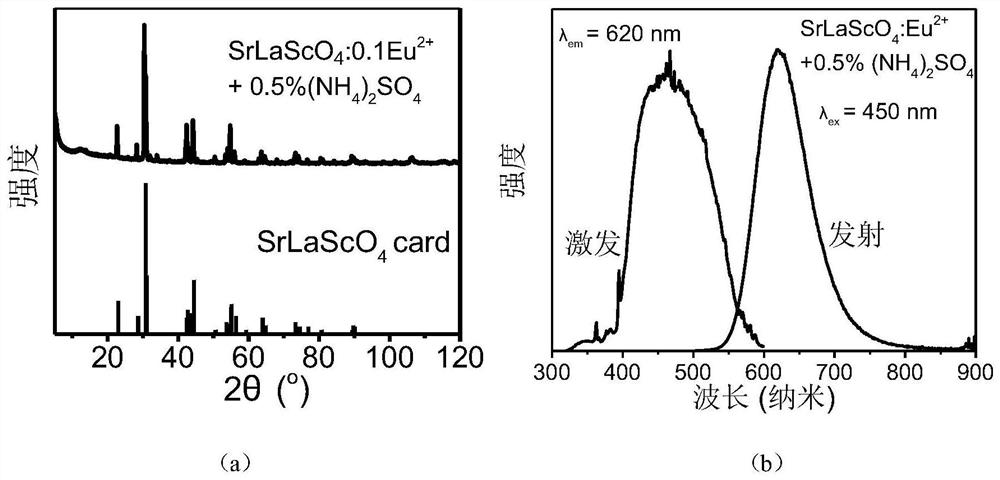

[0049] The phase diagram of the red fluorescent powder described in this embodiment is as attached image 3 Shown in (a), the fluorescent powder of the present invention corresponds to a standard card; its excitation and emission spectra are as attached image 3 As shown in (b), the excitation spectrum of the sample is monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com