Method for preparing conjugated linoleic acid based on tobacco seed oil

A technology of conjugated linoleic acid and tobacco seed oil, which is applied in the preparation of carboxylate salts, chemical instruments and methods, and the preparation of organic compounds. It can solve problems such as corrosion of production equipment, failure to recycle, and environmental pollution, and avoid corrosion. , high conversion rate of conjugated linoleic acid, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

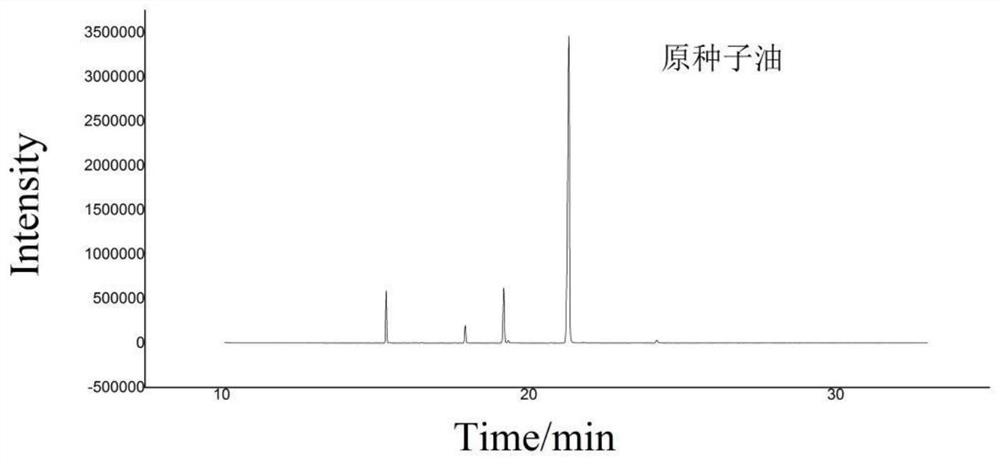

Image

Examples

preparation example Construction

[0035] In the present invention, the KF / Al 2 o 3 The loading amount of KF in the solid base catalyst is preferably 30-55 wt%, more preferably 35-50 wt%, even more preferably 45 wt%. The present invention is to described KF / Al 2 o 3 The source of the solid base catalyst has no special requirements, and the conventional commercially available KF / Al in this field is used 2 o 3 Solid base catalyst or self-preparation can be used. When self-prepared, the KF / Al 2 o 3 The preparation method of solid base catalyst preferably comprises the following steps:

[0036] (a) Al 2 o 3 Carry out activated roasting to obtain activated Al 2 o 3 ;

[0037] (b) KF solution and the activated Al 2 o 3 Mixing, followed by heating and stirring, static aging, drying and roasting to obtain KF / Al 2 o 3 solid base catalyst.

[0038] The present invention will Al2 o 3 Carry out activated roasting to obtain activated Al 2 o 3 . In the present invention, the activation roasting is prefer...

Embodiment 1

[0048] Weigh 6g of A1 2 o 3 , placed in a muffle furnace, roasted at 400°C; weighed 6.48g of KF·2H 2 O, add deionized water to prepare a solution with a concentration of 12%, fully dissolve and add activated A1 after roasting 2 o 3 For the carrier, the temperature of the mixed solution was raised to 60°C, fully stirred, after immersion for 4 hours, left to age for 20 hours, and then dried in a vacuum oven at 80°C for 12 hours. The dried solids were removed, placed in a muffle furnace, and activated at 400°C for 3 hours to obtain KF / Al with a loading capacity of 40wt%. 2 o 3 solid base catalyst.

Embodiment 2

[0050] (1) Take 5mL of tobacco seed oil, add 5mL of phosphate buffer solution with a pH value of 7.5, preheat in a constant temperature shaking box at 40°C and 100r / min for 10min; After the hydrolysis reaction was carried out for 10 h, 10 mL of ethanol with a volume fraction of 95% was added to terminate the reaction. The reaction solution was centrifuged at 1000r / min for 5 minutes, and the upper layer was taken to obtain crude linoleic acid. After calculation, the hydrolysis rate of tobacco seed oil is 81.23%.

[0051] The calculation of hydrolysis rate is shown in formula 1:

[0052] Hydrolysis rate (%) = (AV X -AV 0 ) / (SV-AV)×100 Formula 1;

[0053] In formula 1: AV X is the acid value of the sample after hydrolysis;

[0054] AV 0 is the blank control acid value;

[0055] AV and SV are the acid value and saponification value of the raw oil, respectively.

[0056] The acid value is determined according to "GB / T 5530-2005 Determination of Acid Value and Acidity of An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com