Storage tank for chemical production

A technology for chemical production and storage tanks, which is applied in the direction of tank trucks, final product manufacturing, and reaction engines. It can solve the problems of safe storage of vinyl acetate, corrosion of the outer surface of storage tanks, and large consumption, and achieve the reduction of algae and other microorganisms. The effect of breeding, cleaning and prolonging, ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

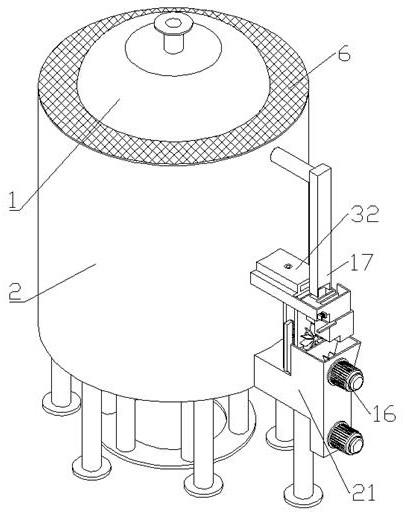

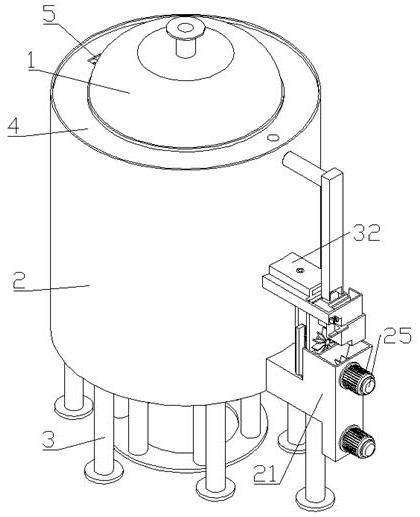

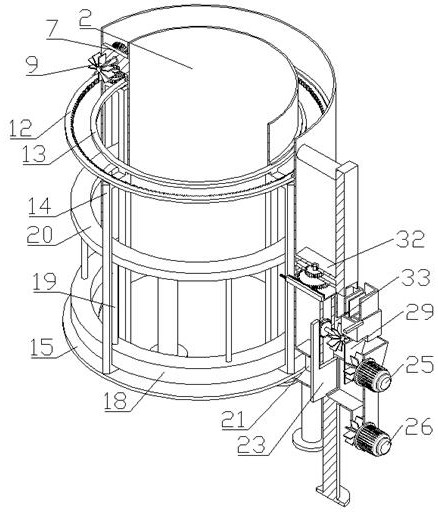

[0020] Such as Figure 1-8 As shown, a storage tank for chemical production includes a storage tank body 1, a cooling water tank 2, a support leg 3, a collection guide ring 4, a collection guide port 5, an annular filter screen 6, a mounting seat 7, and a large bevel gear with shaft 8 , upper toggle paddle 9, small belt shaft bevel gear 10, No. 1 gear 11, ring gear 12, upper support ring 13, hollow scraper 14, lower support ring 15, power generation part 16, control part 17, the storage tank There is a vertical cooling water tank 2 socketed on the outer wall of the body 1. A plurality of vertical support legs 3 are fixed at the bottom of the cooling water tank 2. A horizontal collection guide ring 4 is fixed on the top of the cooling water tank 2. The collection guide There is a vertical collection guide port 5 running through the left part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com