Novel full-automatic backwashing self-cleaning filter for filtering liquid

A backwashing, fully automatic technology, applied in fixed filter element filters, filtration and separation, chemical instruments and methods, etc., can solve problems such as poor effect, waste of cost, no automatic cleaning function, etc., and reduce labor and material costs. , Avoid being easily corroded, and reduce the effect of filter element consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

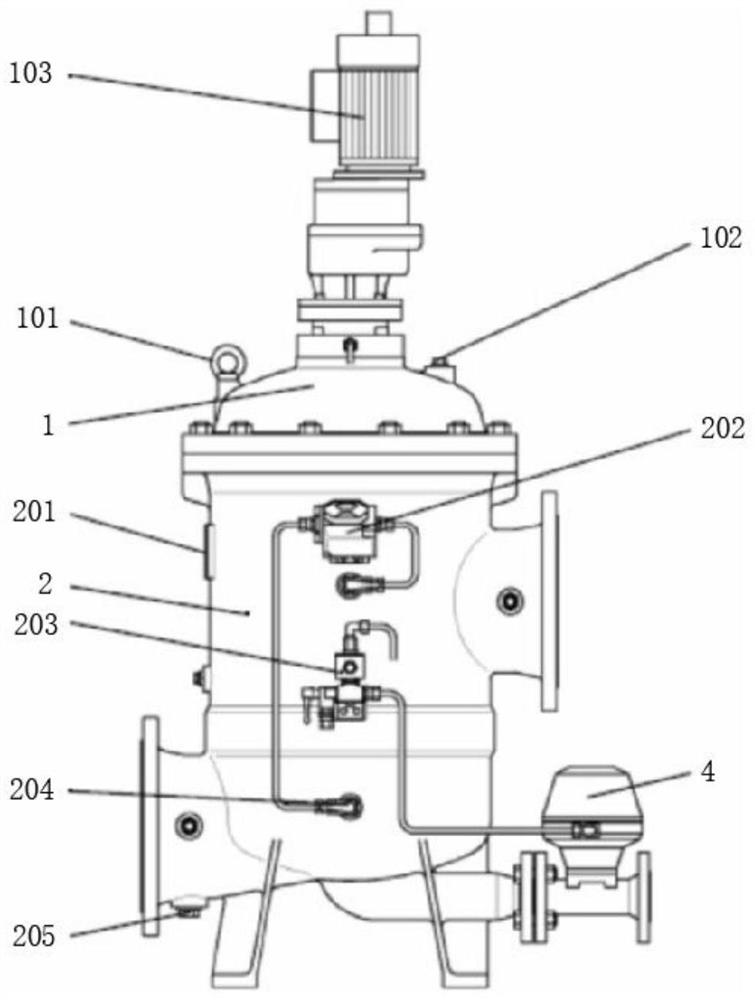

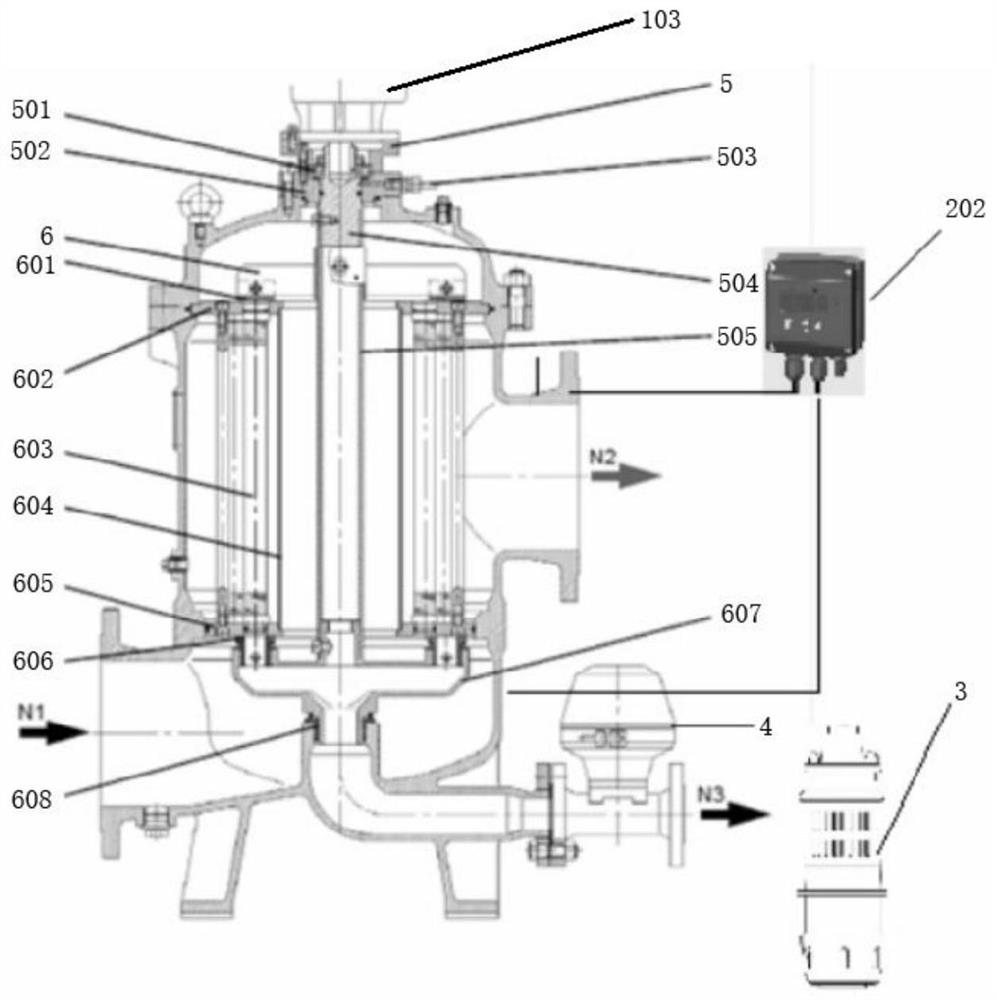

[0027] Such as Figure 1-5 As shown, the present invention provides a new type of fully automatic backwash self-cleaning filter for filtering liquids, including a casing 1, a casing 2 and a sewage pump 3, and the casing 1 and casing 2 are bolted and hermetically connected through a flange structure. , the casing 1 includes an inlet N1, an outlet N2 and a backwash sewage button N3, a lifting point 101 is installed on one side of the surface of the casing 1, and an air release valve 102 is installed on the other side of the surface of the casing 1, the casing 1 A gear motor 103 is installed in the middle of the top of the housing 2, a nameplate 201 is installed on one side of the housing 2, a differential pressure indicator 202 is installed on one side of the nameplate 201, and a solenoid valve 203 is installed on the bottom side of the differential pressure indicator 202. A ball valve 204 is installed on the bottom side of the ball valve 203, a residual discharge valve 205 is i...

Embodiment 2

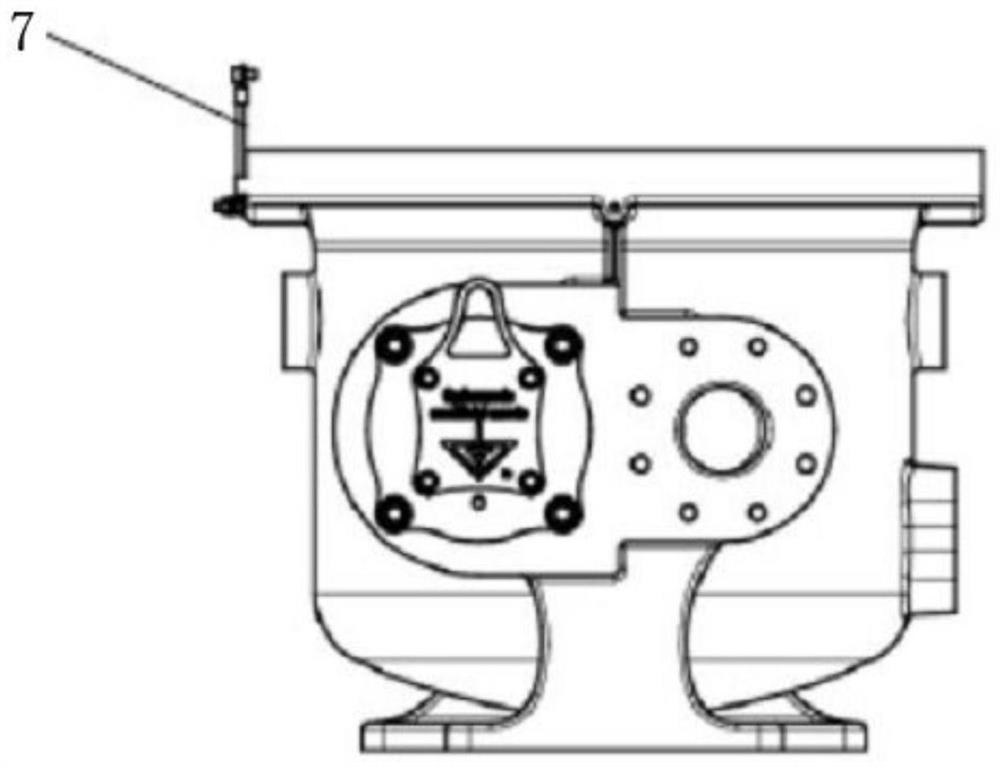

[0044] The surface edge of the entrance N1 is provided with a grounding point 7, the surface edge of the entrance N1 is provided with an observation opening 701, and the inner wall of the entrance N1 is equipped with a sacrificial electrode 702. The groove structure is fixed.

[0045] The inlet N1 and the casing 1 are detachably connected, and the surface of the inlet N1 is arranged in an arc shape. The casing 1, the shell 2 and the inlet N1 are all integrally cast with alloy steel materials, and other structures are the same as in the first embodiment.

[0046] When the inlet N1 is detachable, it can be easily replaced. The sacrificial electrode 702 is designed to anodically protect the filter element. The anodic protection device can prolong the life of the filter element 603 made of metal materials and prevent it from being easily corroded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com