A kind of preparation method of wind tunnel heater containing special-shaped air pipe

A heater and air pipe technology, which is applied in the field of wind tunnel heater preparation with special-shaped air pipes, can solve problems such as difficult to ensure brazing gap, uncontrollable assembly quality, and affecting brazing quality, so as to reduce processing costs and increase brazing Effect of area and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

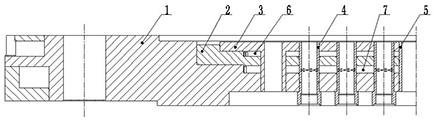

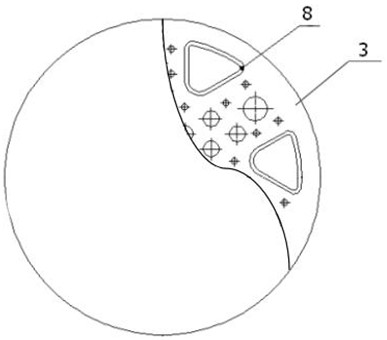

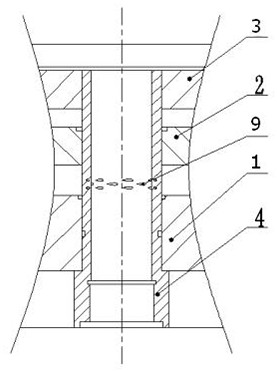

[0044] see Figure 5~Figure 7 , a method for preparing a wind tunnel heater containing a special-shaped air pipe, comprising the following steps:

[0045] (1) Processing fluid nozzle 4, special-shaped air pipe 8, air pipe 5 and shell 1, the assembly positions of liquid nozzle 4, special-shaped air pipe 8, and air pipe 5 are reserved on shell 1;

[0046] (2) After cleaning the liquid nozzle 4, the special-shaped air pipe 8, the air pipe 5 and the shell 1, assemble the liquid nozzle 4, the special-shaped air pipe 8, and the air pipe 5 in the assembly position of the shell 1 in sequence, and then align them through the burr positioning;

[0047] (3) Evenly apply paste-like solder on the liquid nozzle 4, special-shaped air pipe 8, air pipe 5 and shell 1 to be brazed; process the first partition 2, and set up on the first partition 2 for soldering A collecting tank 13 for flow diversion;

[0048](4) Paste the adhesive tape solder on the surface to be brazed of the first partition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com