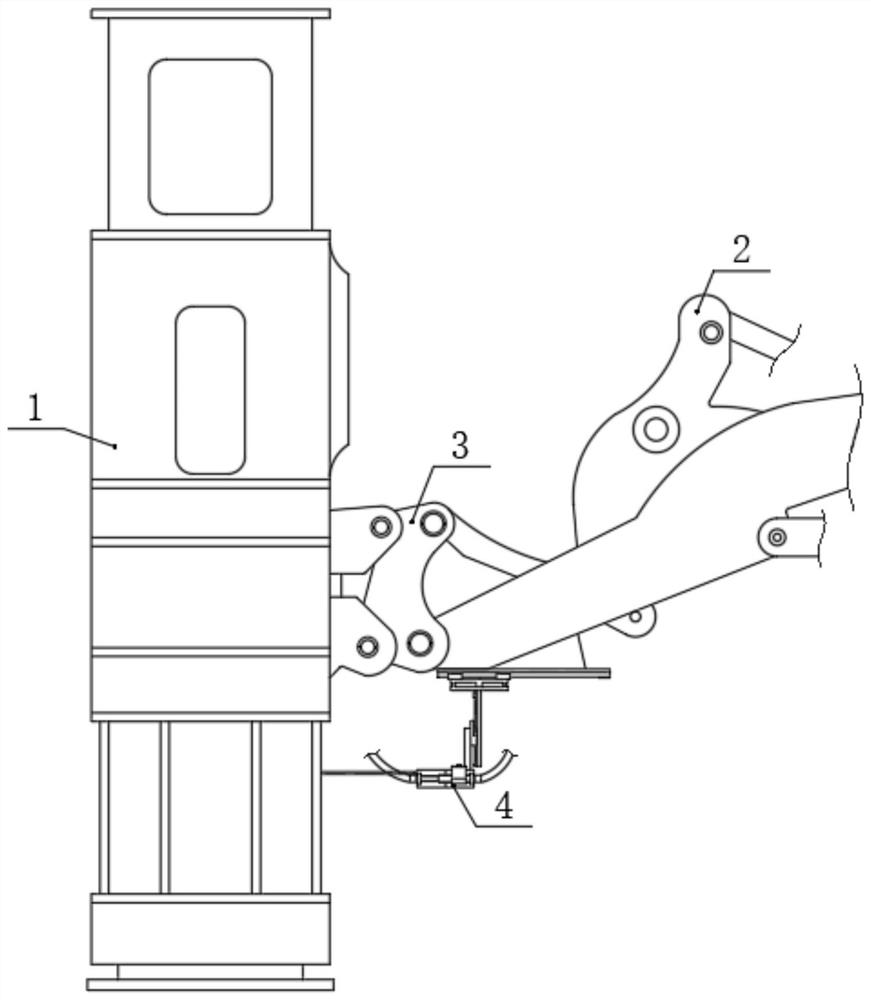

Structure platform back backfilling hydraulic tamping construction method

A structure and hydraulic technology, applied in infrastructure engineering, roads, buildings, etc., can solve the problems of small equipment compaction, damage to structures and road surfaces, affecting driving comfort, etc. Mobility, the effect of enhancing the stability of the roadbed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

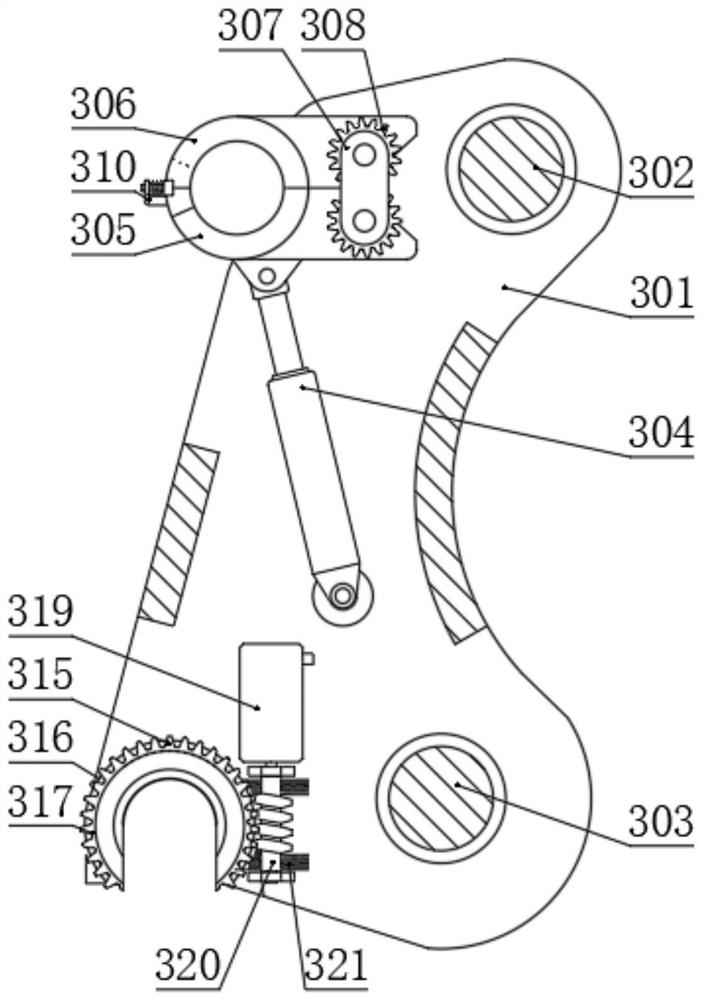

Embodiment Construction

[0036] 1. Construction method test of backfill hydraulic tamping and pressing on the back of the structure:

[0037] The highway test project of a certain section of a provincial highway in a certain city, the route is generally east-west, the main line is 94.265 kilometers long, and there are 2 large bridges, 3 middle bridges, and 1 separate overpass along the entire line. There are 49 reinforced concrete culverts, round pipes There are 234 roads. The climate in the area where the project is located is a semi-arid continental climate, characterized by large temperature differences, dry and windy spring, short summer with hot days and cool nights, very short autumn, long and cold winter, small annual precipitation and large evaporation; The road test project from a certain section of the city's national highway to a certain section, the main line of the route is 130.031 kilometers long, and the structures in this contract section include 2 integral middle bridges, 4 separate m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com