Plastic explosive slitting and weighing device, double-station slitting system and control method of double-station slitting system

A weighing device and double-station technology, applied in the direction of measuring devices, weighing, and weighing equipment for materials with special properties/forms, etc., can solve the problem of direct contact of operators with explosives, high labor intensity, and many operators. problems, to achieve the effect of improving safety production management level and production efficiency, reducing labor intensity and reducing on-site staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

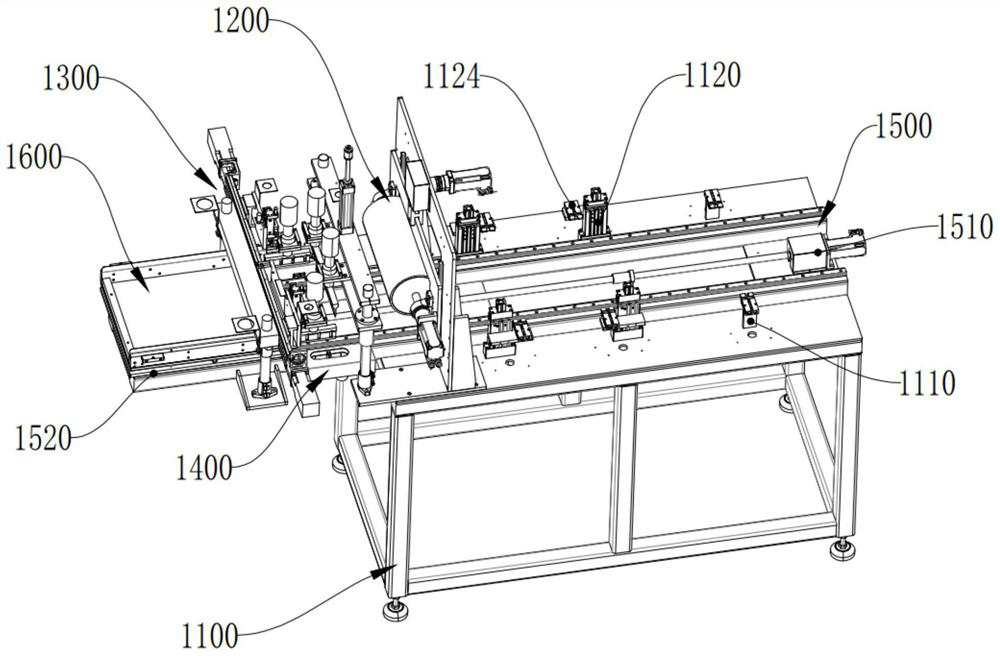

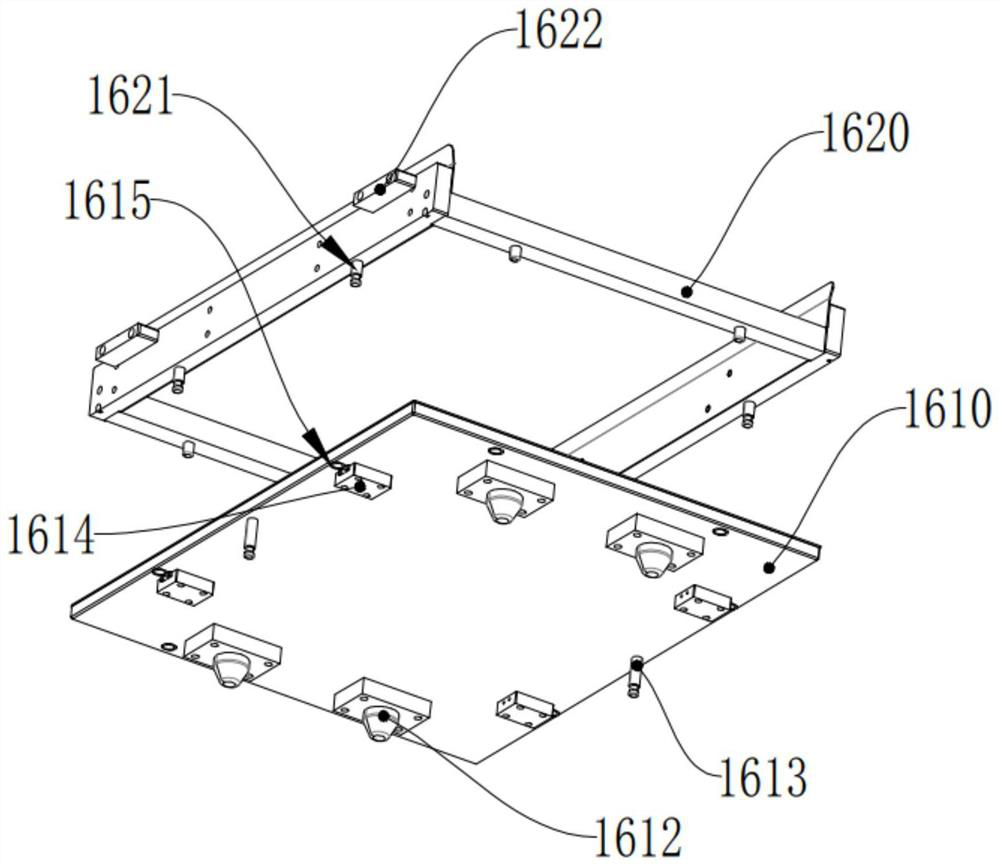

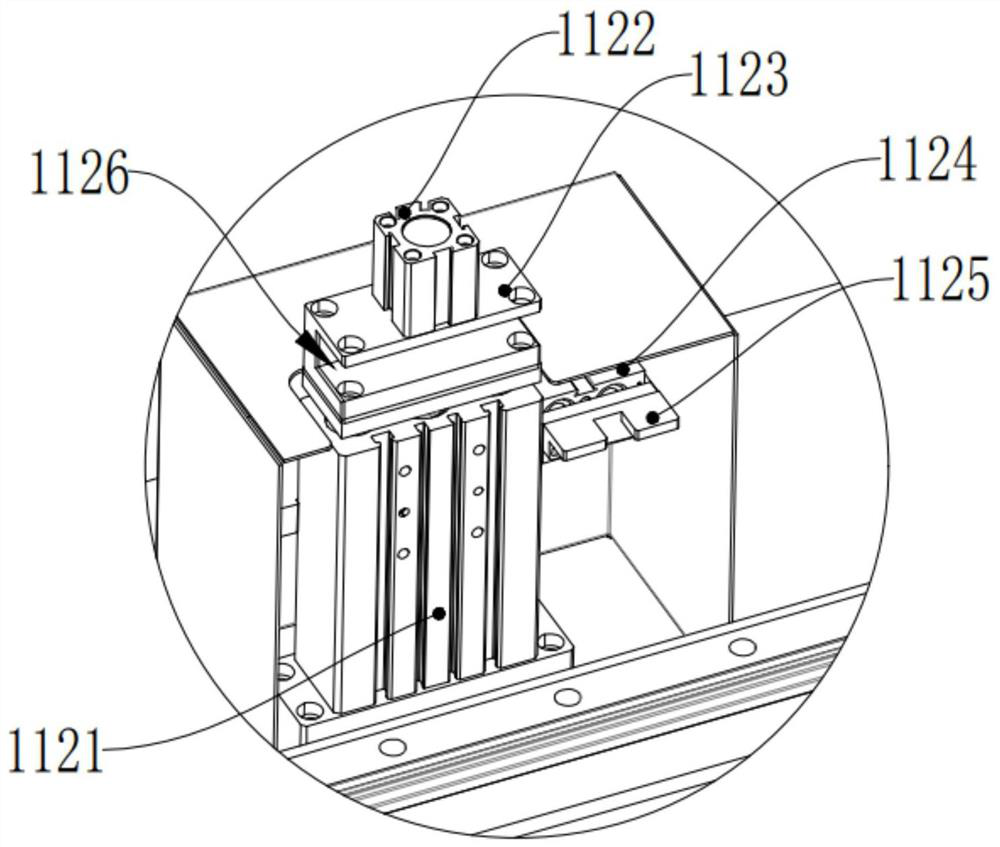

[0070] Plastic explosive cutting and weighing device, refer to the attached figure 1 , including workbench 1100, drug pressing mechanism 1200, drug cutting mechanism 1300, weighing unit 1400, linear moving mechanism 1500 and drug loading tray 1600, linear moving mechanism 1500 is set on working table 1100, drug cutting mechanism 1300 and drug pressing mechanism 1200 are arranged on the linear moving mechanism 1500 front and back, weighing units 1400 are arranged on the left and right sides of the drug cutting mechanism 1300, and the drug-loading tray 1600 is detachably arranged on the movable end of the linear moving mechanism 1500;

[0071] The charge pressing mechanism 1200 is used to roll and flatten the plastic explosive in the charge tray 1600;

[0072] The charge cutting mechanism 1300 is used to cut the plastic explosive in the charge tray 1600 into pieces, and transfer the cut pieces to the weighing unit 1400;

[0073] The weighing unit 1400 is used to weigh the medic...

Embodiment 2

[0113] Double-station cutting system for plastic explosives, please refer to the attached Figure 11 , including the first medicine cutting device 1000, the second medicine cutting device 2000, the tray transmission mechanism 3000, the material receiving mechanism 4100, the anti-explosion transmission mechanism 5000, the recovery box 4300 and the jig conveyor 4200, the first medicine cutting device 1000 and The second medicine cutting device 2000 is a cutting and weighing device;

[0114] The first medicine cutting device 1000 and the second medicine cutting device 2000 are arranged parallel to each other, the tray conveying mechanism 3000 is set at one end of the first medicine cutting device 1000 and the second medicine cutting device 2000, and the material receiving mechanism 4100 is set at the first medicine cutting device 1000 and the other end of the second medicine cutting device 2000, the anti-explosion transmission mechanism 5000 is set at one end of the tray transmis...

Embodiment 3

[0139] A control method for a double-station slitting system for plastic explosives, the method includes the following steps:

[0140] Step S1: the moving bottom plate 1520 of the first medicine cutting device 1000 or the second medicine cutting device 2000 moves to the bottom of the tray conveying mechanism 3000;

[0141] Step S2: The tray transfer mechanism 3000 sequentially transfers the charge-loaded tray 1600 loaded with plastic explosives in the anti-explosion transfer mechanism 5000 to the moving bottom plate 1520 of the first charge cutting device 1000 and the second charge cutting device 2000;

[0142] Step S3: The drug-loaded tray 1600 is moved to the bottom of the drug-pressing mechanism 1200 under the drive of the moving bottom plate 1520. The drug-loading mechanism 1200 is used to roll and flatten the plastic explosive in the drug-loaded tray 1600. After flattening, the drug-loaded tray 1600 moves to the frame lifting part 1120, and the frame lifting part 1120 sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com