Powder and cosmetic preparation

A powder, elastic powder technology, applied in cosmetic preparations, cosmetic preparations, body powders, etc., can solve problems such as lack of touch and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

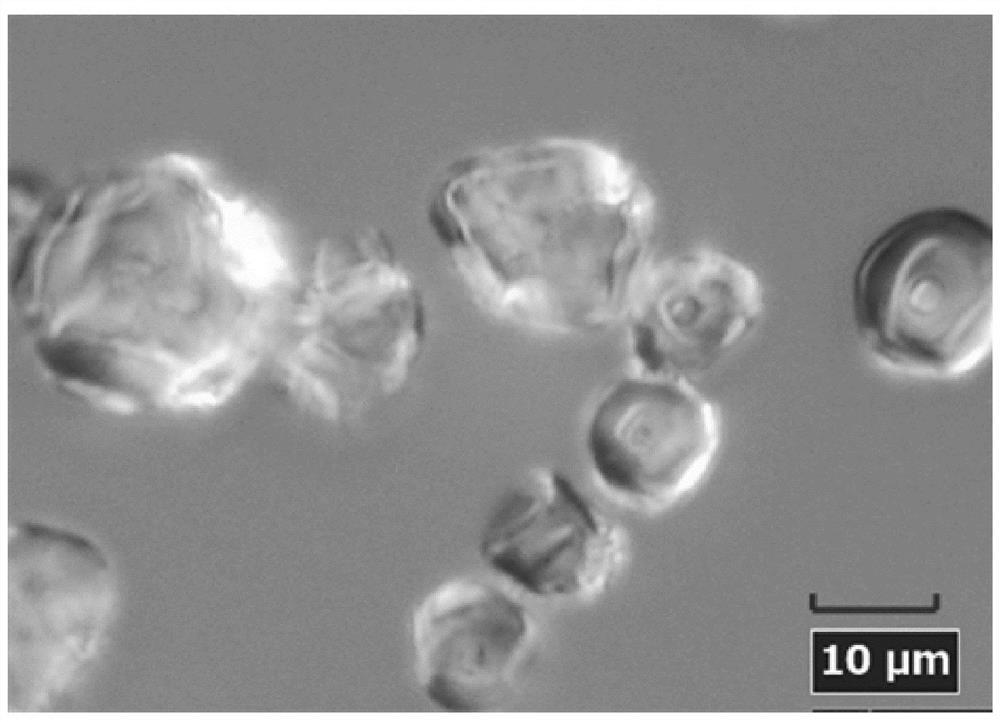

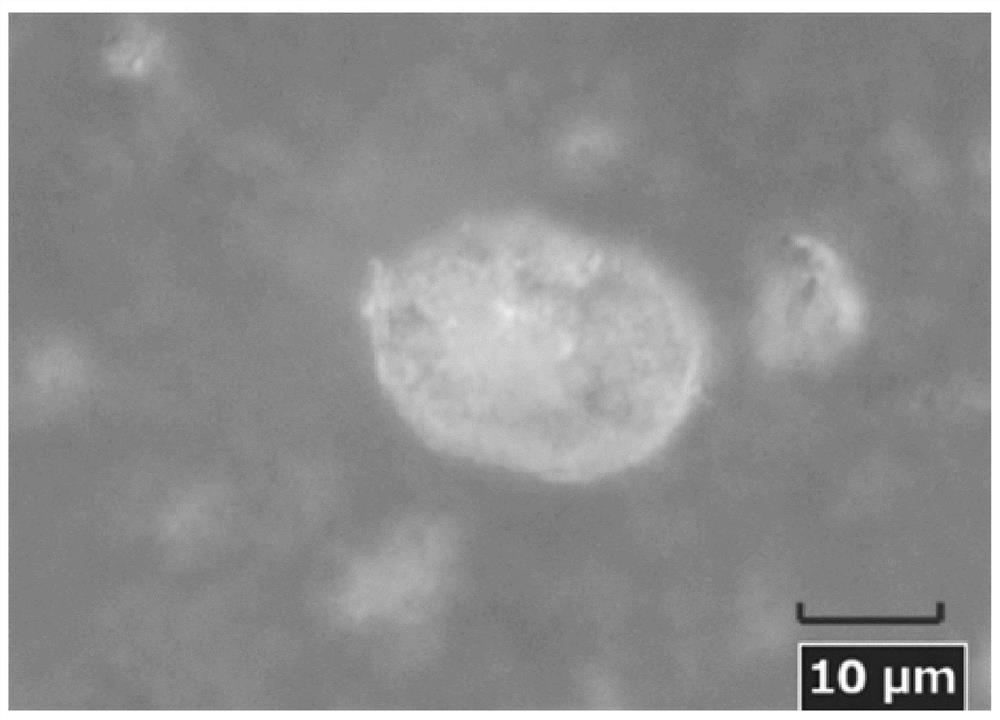

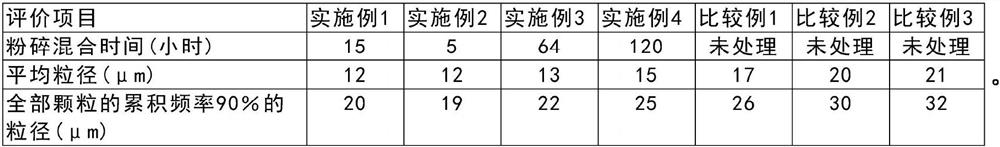

[0033] Weigh 4g of N in a 1L alumina ball mill container ε - lauroyl lysine (Ajinomoto Co., Ltd., AMIHOPE (registered trademark) LL) and 16 g of cornstarch (Nippon Food & Chemical Co., Ltd., cornstarch W). Add 660g of alumina balls with a diameter of 2.0cm and 600g of alumina balls with a diameter of 1.0cm in the container, grind and mix with 100rpm for 15 hours, and obtain a mixture with N attached to the surface. ε - Spherical powder of lauroyl lysine. With respect to the N attached to the surface ε -Confirmation of lauroyl lysine was confirmed by visual observation with an optical microscope (manufactured by Hirox Co., Ltd., RH-2000 digital microscope) ε -Lauroyl lysine is attached to the surface of spherical granules characteristic of cornstarch ( figure 1 and figure 2 ). The elastic modulus of described cornstarch is 2.9 * 10 8 N / m 2 . It should be noted that the elastic modulus of the elastic powder is based on the particle diameter measured particle by particle...

Embodiment 2

[0047] Except that the time of pulverization and mixing was changed to 5 hours, the same operation as in Example 1 was obtained to obtain a mixture with N attached to the surface. ε - Spherical powder of lauroyl lysine. The average particle size was 12 μm, and the particle size at which the cumulative frequency of all particles was 90% was 19 μm.

Embodiment 3

[0049] Except that the time of pulverization and mixing was changed to 64 hours, the same operation as in Example 1 was obtained to obtain a mixture with N attached to the surface. ε - Spherical powder of lauroyl lysine. The average particle size was 13 μm, and the particle size at which the cumulative frequency of all particles was 90% was 22 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com