Low-temperature gas nitriding method for high-strength austenitic stainless steel

A technology of austenitic stainless steel and low-temperature gas, which is applied in workpiece surface treatment equipment, coating, metal rolling, etc., can solve the problems of gas nitriding process difficulty and diffusion difficulty, and improve the difficulty and effect of low-temperature gas nitriding Obvious effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

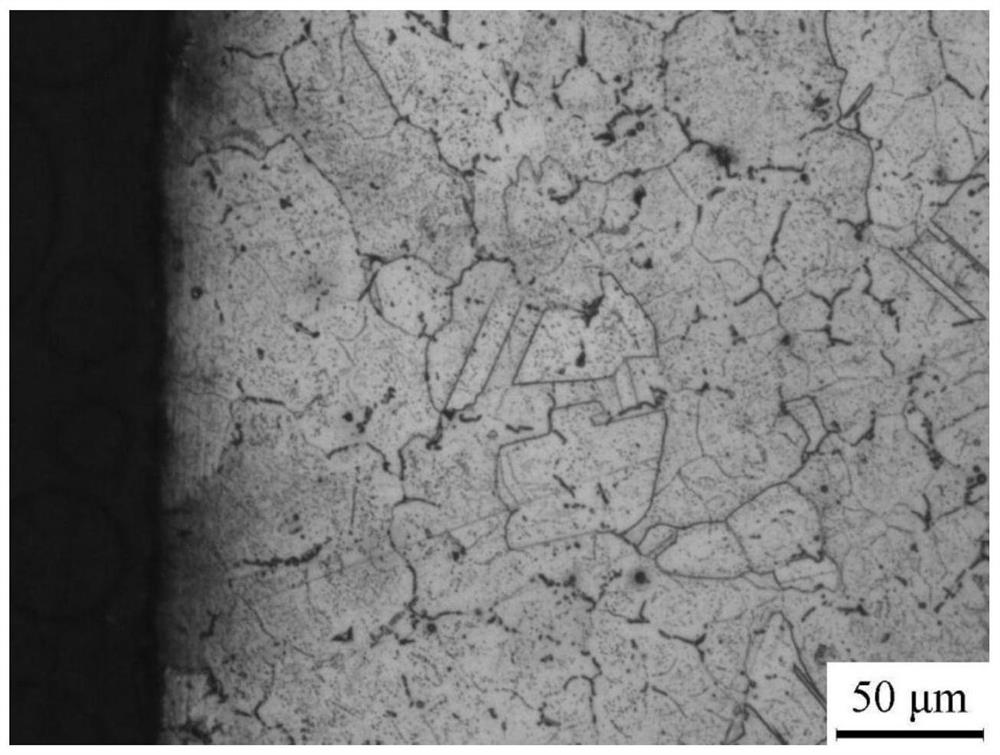

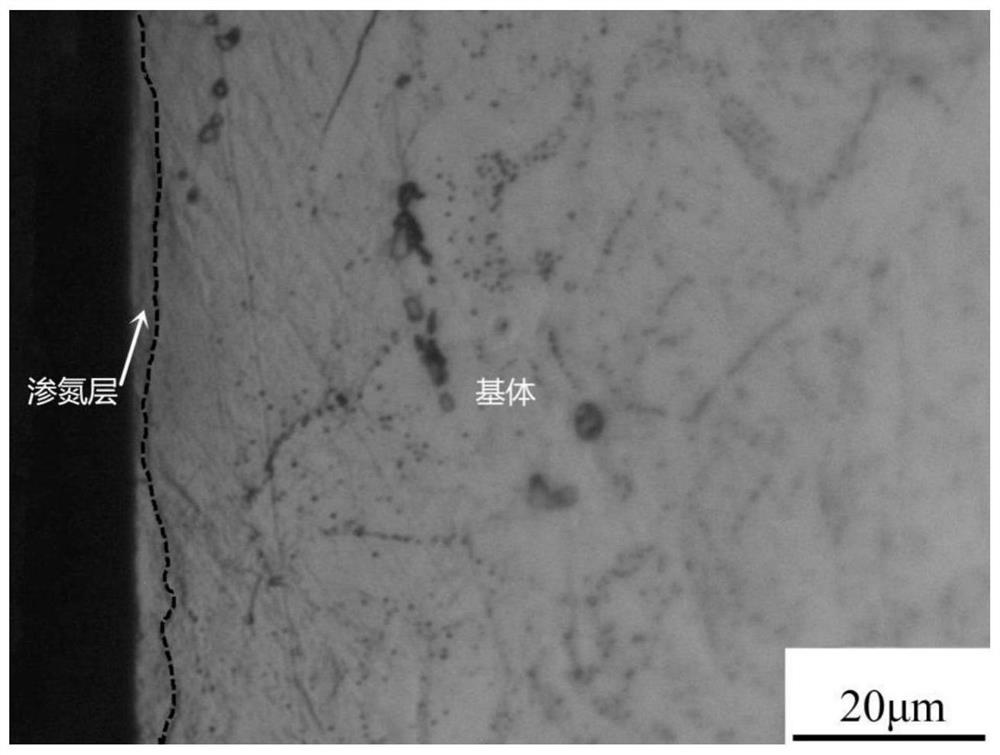

Embodiment 1

[0071] In terms of mass percentage, the chemical composition of the high-strength austenitic stainless steel used in this embodiment is: Cr 18.9%, Mn 19.3%, Ni 2.0%, C 0.11%, and the balance is iron.

[0072] The high-strength austenitic stainless steel is subjected to solution treatment by water cooling after heat preservation at 1150°C for 1 hour to obtain steel for testing;

[0073] The test steel with a thickness of 10 mm is rolled on a rolling mill for multiple passes, the reduction of each pass is 5%, and the final reduction after rolling is 50%, to obtain rolled steel;

[0074] Put the rolled steel into ultrasonically oscillating absolute ethanol, and clean it for 2 minutes at an ultrasonic power of 80 kHz; Take it out after washing for 3 minutes, and dry the surface of the sample to obtain activated steel;

[0075] Put the activated steel in the nitriding furnace, evacuate the inner tank of the nitriding furnace, fill it with ammonia gas at a rate of 1L / min, fill the ...

Embodiment 2

[0080] The preparation method is basically the same as in Example 1, except that the nitriding time is adjusted from "6h" to "12h".

Embodiment 3

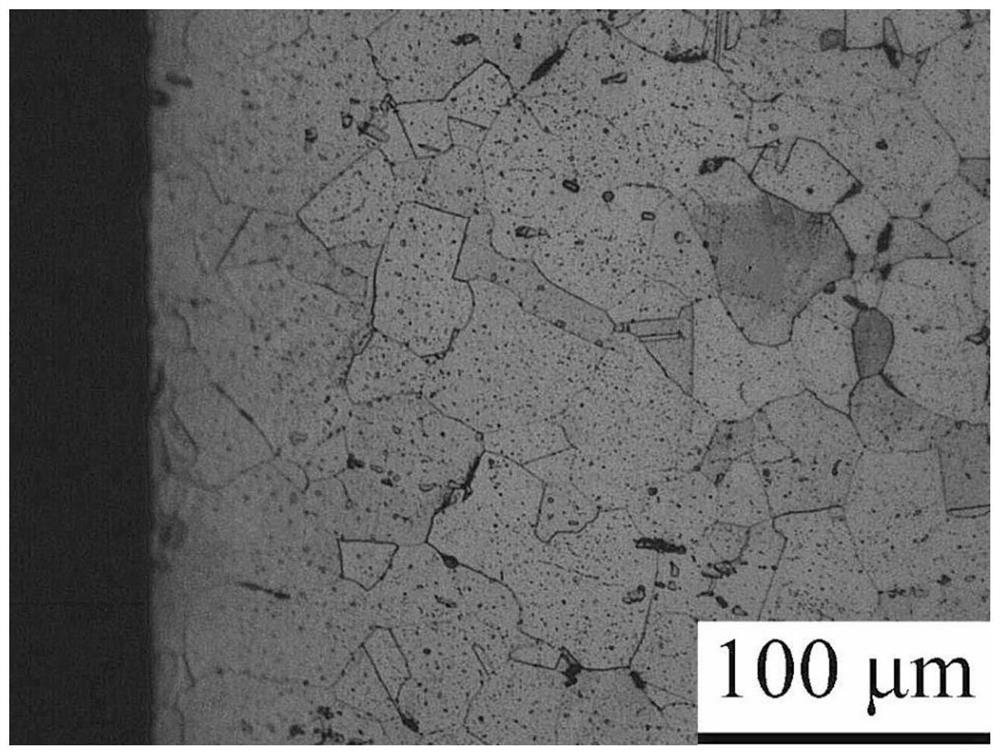

[0094] In terms of mass percentage, the chemical composition of the high-strength austenitic stainless steel used in this embodiment is: C 0.013%, Mn 24.86%, Cr 17.26%, N 0.008%, and the balance is iron.

[0095] The high-strength austenitic stainless steel is subjected to solution treatment by water cooling after heat preservation at 1150°C for 1 hour to obtain steel for testing;

[0096] The test steel with a thickness of 10 mm is rolled on a rolling mill for multiple passes, the reduction of each pass is 5%, and the final reduction after rolling is 50%, to obtain rolled steel;

[0097] Put the rolled steel into ultrasonically oscillating absolute ethanol, and clean it for 2 minutes under the condition of ultrasonic power of 80 kHz; then put it into 2wt% phosphorous acid + 4wt% hydrochloric acid solution at 50°C for pickling for 3 minutes and take it out. Dry the surface of the sample to obtain activated steel;

[0098] Put the activated steel in the nitriding furnace, evac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com