Catalyst for preparing 2-methyl furan through furfural gas phase hydrogenation, and preparation method thereof

A technology for the preparation of methyl furan and hydrogen, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of aggregation and growth of active component copper particles, experimental Conditions are difficult to control and other problems, to achieve the effect of simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

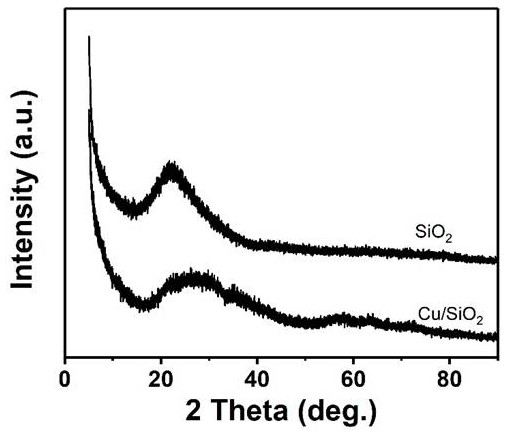

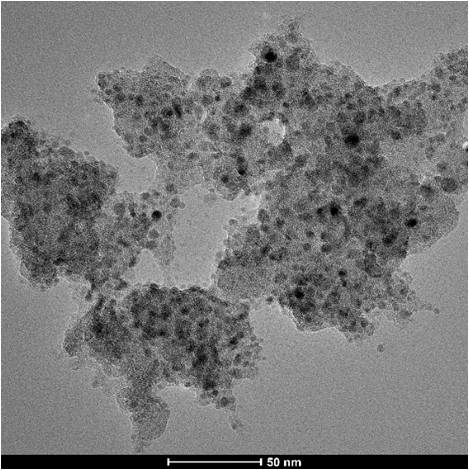

Image

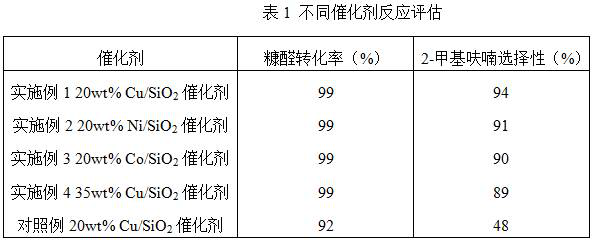

Examples

Embodiment 1

[0035] A kind of catalyst 20wt% Cu / SiO for preparing 2-methylfuran by gas-phase hydrogenation of furfural 2 (The percentage in front of the catalyst represents the loading capacity of the active component, the same below) The preparation method, the steps are as follows:

[0036] Preparation of S1, Cu NPs solution:

[0037] S1.1. Weigh 3 mL of polyethylene glycol 200 into a beaker and add 1.4 mL of CuCl 2 solution (2 g / mL), stirred in an ice-water bath at 0 °C for 10 min;

[0038] S1.2. Dialysis bag pretreatment: cut the dialysis bag (molecular weight cut-off 1000 mesh) into small pieces with a length of 5 cm, and prepare NaHCO 3 solution (0.01g / mL) and EDTA disodium solution (0.1g / mL), take 100 mL each in a 250 mL beaker, put the dialysis bag in the beaker and boil for 30 min, wash the dialysis bag with deionized water, and then put the dialysis bag Put in 100 mL EDTA disodium solution (0.1g / mL) and boil for 20 min, cool to room temperature, store at 4 ℃ for later use;

...

Embodiment 2

[0046] Catalyst 20wt% Ni / SiO for preparing 2-methylfuran by gas-phase hydrogenation of furfural 2 The preparation method, the steps are as follows:

[0047] Preparation of S1, Ni NPs solution:

[0048] S1.1. Weigh 5 mL of polyethylene glycol 200 into a beaker and add 0.3 mL of NiCl 2 (10 g / mL) solution, stirred in an ice-water bath at 5°C for 15 min;

[0049] S1.2. Dialysis bag pretreatment: same as step S1.1 in Example 1;

[0050] S1.3. Under the condition of stirring in ice-water bath, add NaBH dropwise with a dropper 4 Solution (0.1 mol / L) solution 10 mL (ready to use), drop it within 10 minutes, continue to stir for 3 hours after the dropwise addition, pour the solution into the dialysis bag in step S1.2, put L deionized water as the dialysate) was stirred for 8 h, and the dialyzed aqueous solution was replaced for 4 h, and finally the solution in the dialyzed bag was transferred to a 500 mL beaker;

[0051] S1.4. Add NaOH solution (0.1 g / mL) dropwise to the solution ...

Embodiment 3

[0055] A kind of catalyst 20wt% Co / SiO for preparing 2-methylfuran by gas-phase hydrogenation of furfural 2 The preparation method, the steps are as follows:

[0056] Preparation of S1, Co NPs solution:

[0057] S1.1. Weigh 6 mL of polyethylene glycol 200 and add 0.15 mL of CoCl 2 (20 g / mL) solution, stirred in an ice-water bath at 2°C for 20 min;

[0058] S1.2. Dialysis bag pretreatment: same as step S1.1 in Example 1;

[0059] S1.3. Under the condition of stirring in ice-water bath, add NaBH dropwise with a dropper 4 solution (0.1 mol / L) solution 15 mL (ready to use), drop it within 10 min, continue to stir for 3 h after the dropwise addition, pour the solution into the dialysis bag in step S1.2, put L deionized water as the dialysate) was stirred for 7 h, the dialyzed aqueous solution was replaced for 3 h, and finally the solution in the dialyzed bag was transferred to a 500 mL beaker;

[0060] S1.4. Add NaOH solution (0.1 g / mL) dropwise to the solution obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com