Production device of HDPE pipe

A preparation device and pipe technology, applied in the field of HDPE pipe preparation devices, can solve the problems of increased power consumption, cost increase, product yellowing, etc., and achieve the effects of improving the quality of finished products, increasing the moving time, and increasing the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

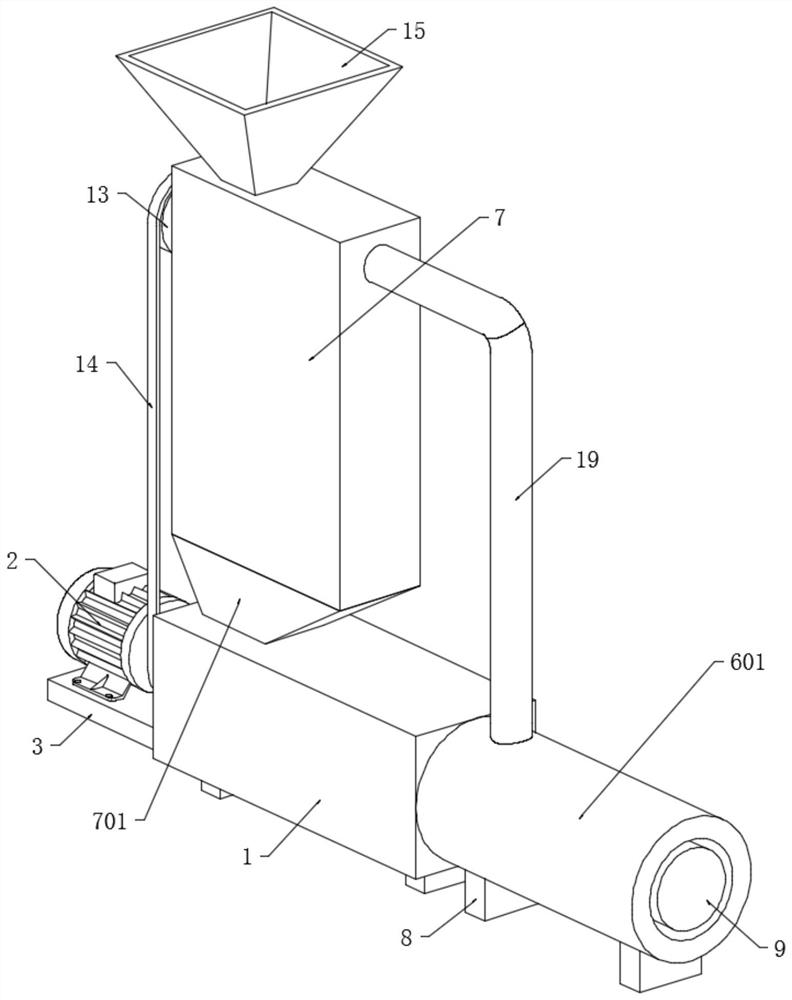

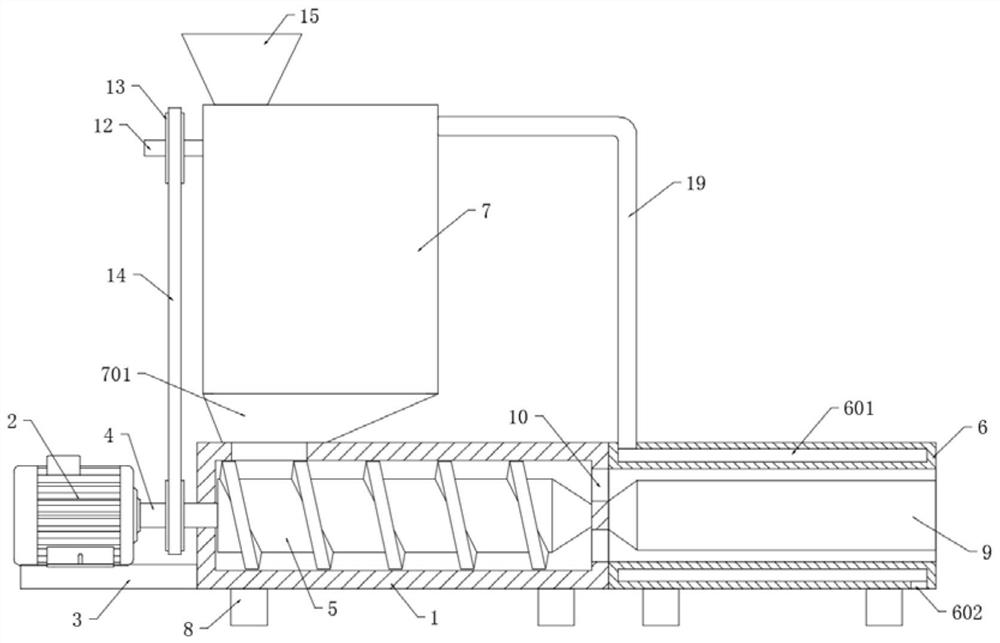

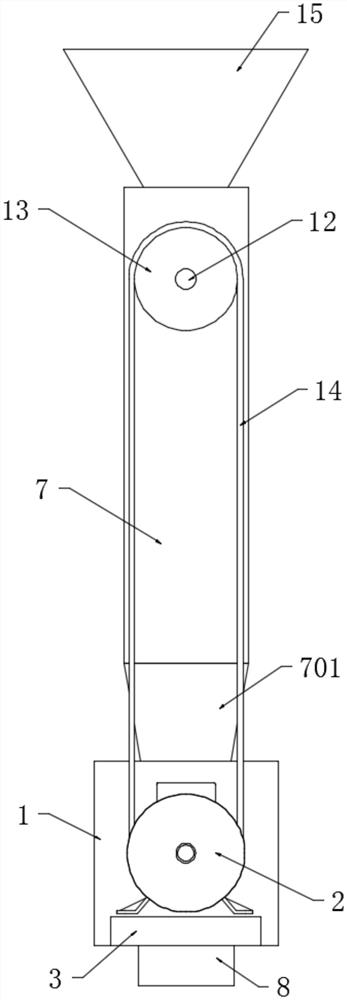

[0027] refer to Figure 1-6 , a preparation device for HDPE pipes, comprising an extrusion box 1, a motor 2 and a feeding box 7, the outer wall of one side of the extrusion box 1 is fixedly connected with a mounting plate 3, and the shell of the motor 2 is fixedly connected to the mounting plate 3 by bolts Above, the motor 2 extrusion box 1 close to the motor 2 side of the center of the box wall is rotationally connected with the main shaft 4, one end of the main shaft 4 is coaxially welded with the output shaft of the motor 2, and the main shaft 4 is located at one end of the extrusion box 1 The extruding screw 5 is coaxially welded, the outer wall of the extrusion box 1 away from the motor 2 is fixedly connected with the forming die tube 6, the bottom of the extrusion box 1 and the forming die tube 6 is fixedly connected with the supporting foot 8, and the feeding box The bottom of 7 is sealed with a connecting bucket 701, and the lower end of the connecting bucket 701 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com