Mold for bending and forming thick glass tube and using method thereof

A technology for bending and forming glass tubes, applied in the field of moulds for bending and forming thick glass tubes, can solve problems such as uneven heating of glass tubes, and achieve the effects of reducing heat loss, improving energy conservation and environmental protection performance, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

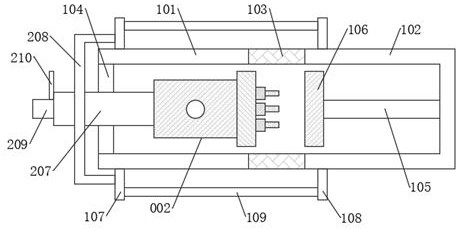

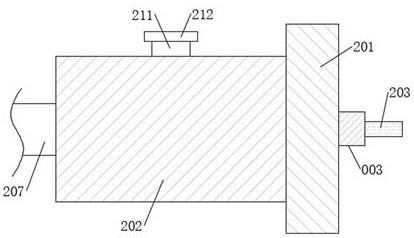

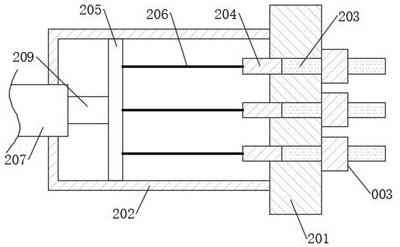

[0051] see Figure 1-10 , a kind of mold for bending and forming a rough glass tube, including matching left half-mold 101 and right half-mold 102, one end of the left half-mold 101 away from the elastic connection frame 103 is provided with a through hole 104, and the right half-mold 102 is away from the elastic connection A fixing rod 105 is fixedly connected to the inner wall of one end of the frame 103, one end of the fixing rod 105 is fixedly connected with a solid heat-insulating plug 106, and a matching elastic connection frame is fixedly connected between the left half-mould 101 and the right half-mould 102. 103. Left magnet blocks 107 are fixedly connected to the outer walls of the upper and lower sides of the left half-mould 101, and right magnet blocks 108 are fixedly connected to the outer walls of the upper and lower sides of the right half-mould 102. An iron connecting rod 109 is arranged between the magnet blocks 108. Through the arrangement of the left magnet b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com