Phenylacetic acid synthesis method

A synthesis method and technology of phenylacetic acid, applied in the direction of carbon monoxide reaction to prepare carboxylic acid, organic chemistry, etc., can solve the problems of low total yield, high cost, high yield of hydrolysis process, etc., and achieve the effect of improving the synthesis reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

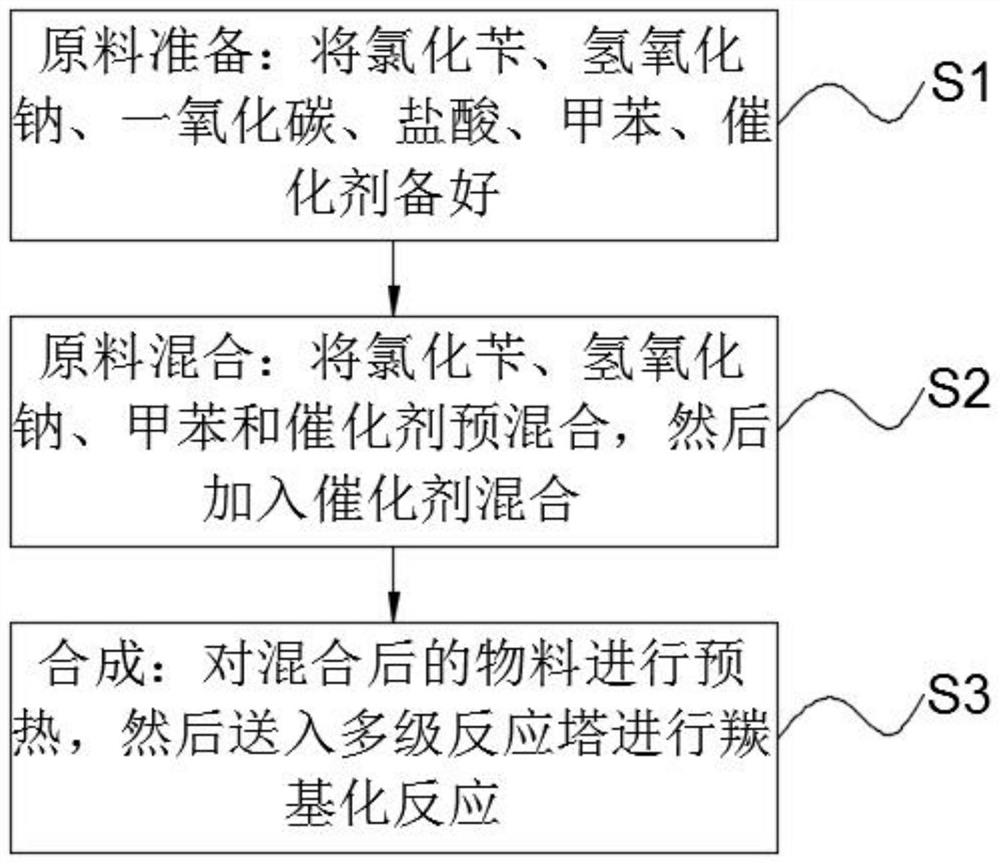

[0022] A synthetic method for phenylacetic acid, comprising the following steps:

[0023] S1. Raw material preparation: prepare benzyl chloride, sodium hydroxide, carbon monoxide, hydrochloric acid, toluene, and catalyst, and the above raw materials are provided by public works, storage tanks or supporting projects;

[0024] S2, raw material mixing: premix benzyl chloride, sodium hydroxide, toluene and catalyst, then enter the mixing tank, and add catalyst (catalyst is recycled under normal circumstances, only need intermittent small amount of supplement) to mix;

[0025] S3. Synthesis: The material in the mixing tank is transported to the reaction material preheater with the reaction tower feed pump (2.0-2.5Mpa), preheated to 65-75°C, and then enters the synthesis heat exchanger to preheat with the circulating material to 65-75°C, and then enter the gas-liquid mixer at the bottom of the reaction tower A, and mix it with the unreacted carbon monoxide from the reaction B tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com