Method for preparing polyvinylpolypyrrolidone

A technology of cross-linked povidone and cross-linking agent is applied in the field of preparing cross-linked povidone, which can solve the problems of unsatisfactory yield, side reaction, lack of competitiveness, etc., and achieves improvement in quality, particle size, and market. The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

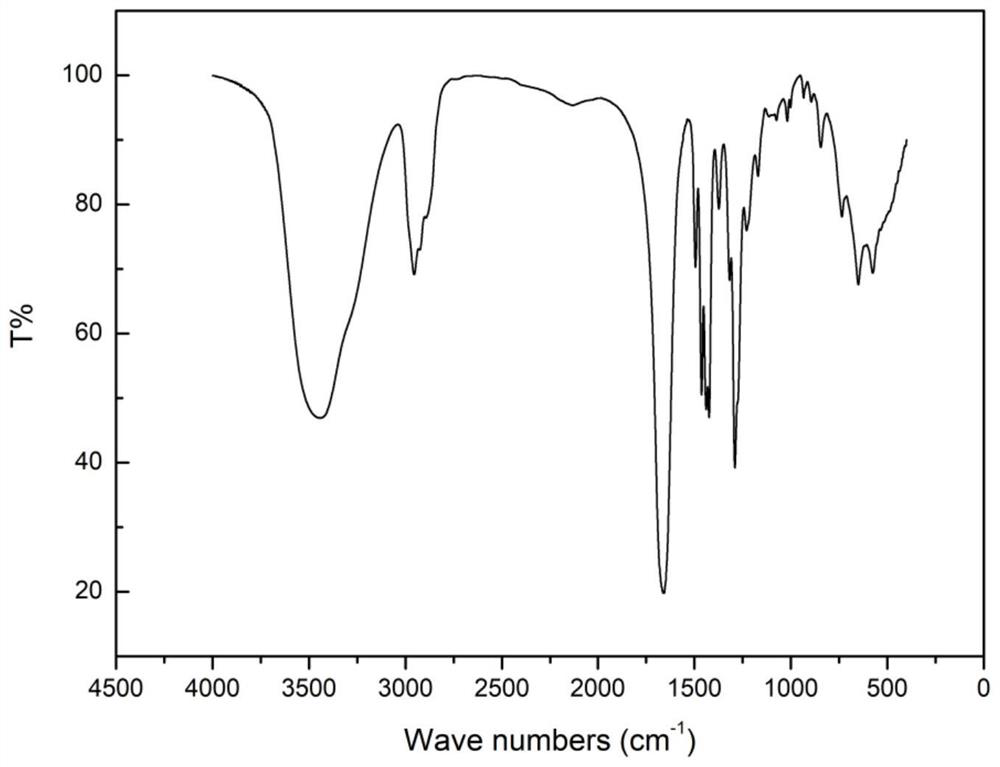

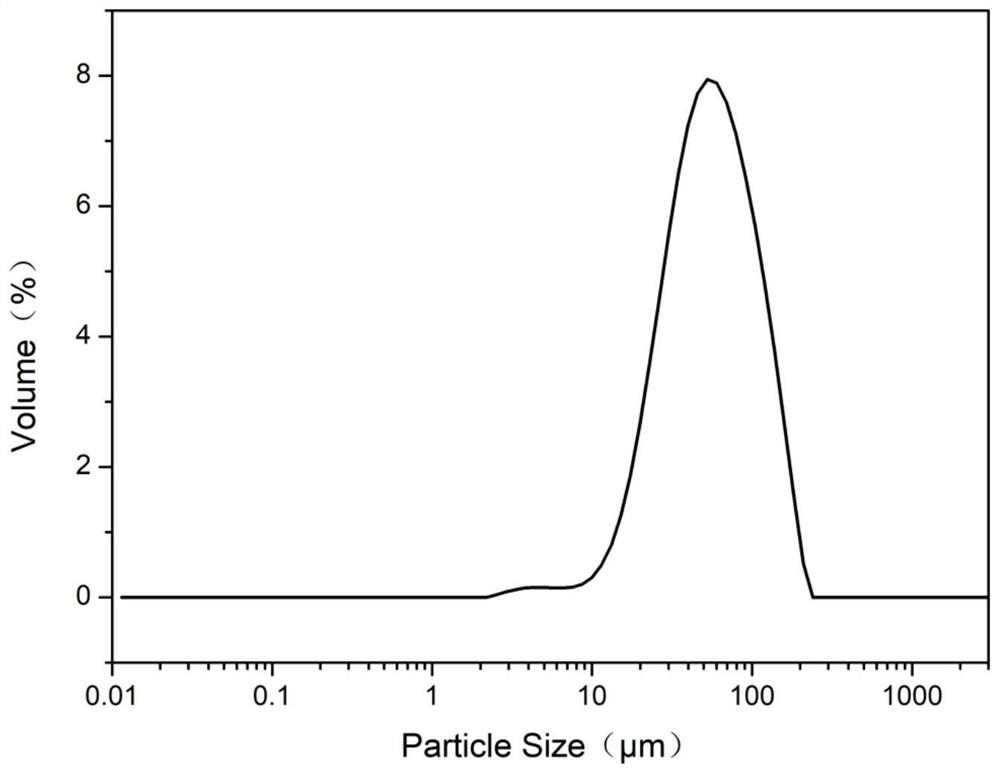

[0026] refer to figure 1 , image 3 , Figure 6 , a method for preparing crospovidone, the process is as follows: NVP, water, and NaOH are put into the reaction kettle according to mass fractions of 100g, 15.1g, and 1g respectively, and then 1.0g of crosslinking agent is added, and replaced with nitrogen to remove Oxygen in the bottle, turn on the stirrer and heat to 140°C under the protection of nitrogen at 0.2MPa pressure, keep it warm for 190min, observe the obvious temperature rise on the thermometer, indicating that the reaction has started, until the temperature no longer rises, indicating that the popcorn polymerization reaction is over , the temperature was lowered to 70° C. by cooling water, the product was taken out, washed with water and dried to obtain a crospovidone product with a yield of 92.2%.

Embodiment 2

[0028] A method for preparing crospovidone, the process is as follows:

[0029] Put NVP, water, and NaOH into the reaction kettle according to the mass fraction of 100g, 15.1g, and 1.0g respectively, then add 1.0g of crosslinking agent, replace with nitrogen to remove the oxygen in the bottle, and turn on the stirrer under 0.2MPa pressure of nitrogen Heated to 135°C under protection and kept warm for 190min. Observing a significant temperature rise on the thermometer indicates that the reaction has begun. When the temperature stops rising, it indicates that the popcorn polymerization reaction is over. Cool the temperature to 70°C with cooling water, take out the product, wash and dry dry to obtain a crospovidone product with a yield of 88.4%.

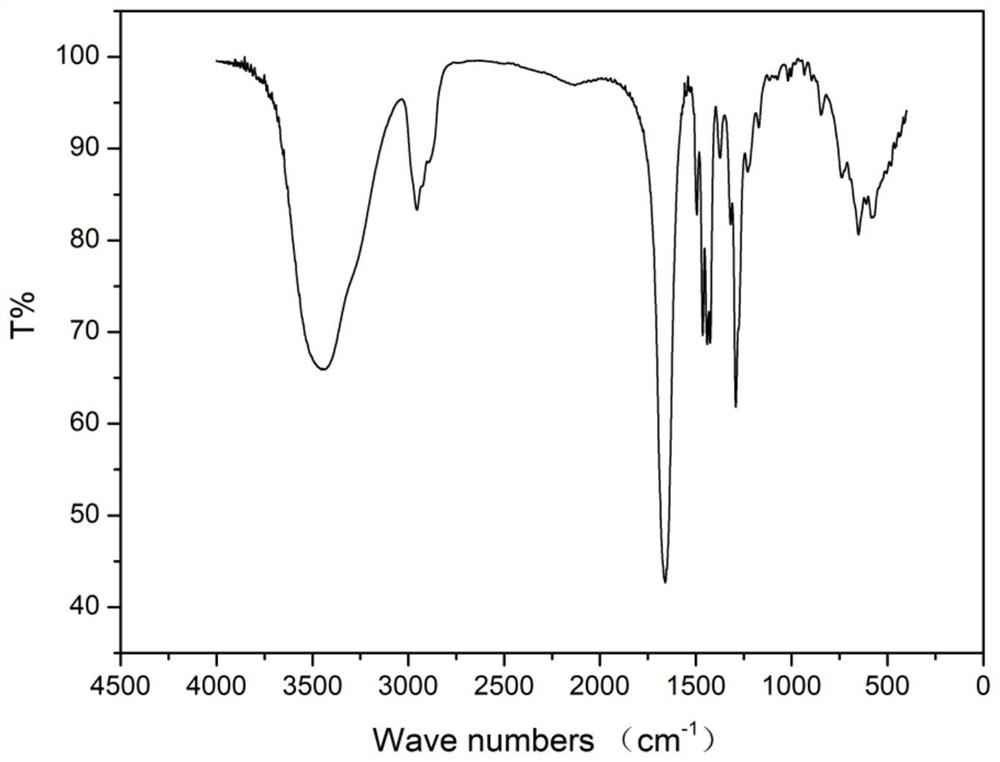

Embodiment 3

[0031] A method for preparing crospovidone, the process is as follows:

[0032] Put NVP, water, and NaOH into the reaction kettle according to the mass fraction of 100g, 15.1g, and 1.0g respectively, then add 1.0g of crosslinking agent, replace with nitrogen to remove the oxygen in the bottle, and turn on the stirrer under 0.2MPa pressure of nitrogen Heating to 130°C under protection, keeping it warm for 190min, observing that the temperature rises obviously on the thermometer indicates that the reaction has started, until the temperature no longer rises, indicating that the popcorn polymerization reaction is over, cool down to 70°C with cooling water, take out the product, wash and dry dry to obtain a crospovidone product with a yield of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com