Acid anhydride and epoxy high-molecular chain extension tackifier, and preparation method and application thereof

An epoxy and polymer technology, applied in the application field of polymer chain extension tackifier, can solve the problems of low processing efficiency of biodegradable plastic products, unstable improvement of polyester properties, uncontrollable toxicity of additives, etc. Achieve important application value and economic benefits, not easy to migrate, and use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

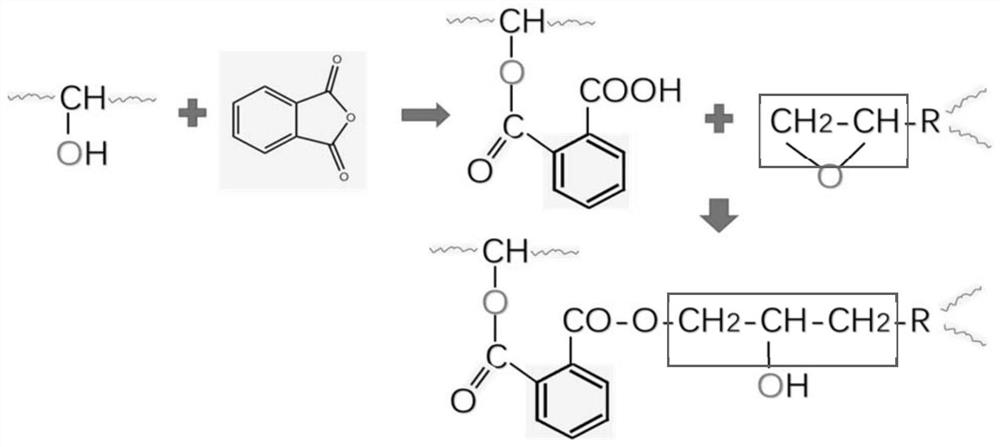

Method used

Image

Examples

Embodiment 1~3

[0035] The preparation of embodiment 1~3 acid anhydride and epoxy polymer chain extension tackifier

[0036] 1. The materials of each embodiment are calculated by mass, the unit is g, and the consumption is as shown in Table 1:

[0037] Table 1

[0038]

[0039] 2. Preparation process of acid anhydride and epoxy polymer chain extension tackifier

[0040] S1. Put a certain amount of matrix material in the container, BASF 1010 is an antioxidant, BASF As a heat stabilizer, the temperature is controlled at 100°C through an oil bath;

[0041] S2. Add a certain amount of glycidyl additives and acid anhydride additives into the container, keep stirring at 100°C for 2 hours, and the reaction is complete;

[0042] S3. The product may agglomerate after cooling, which can be mashed or broken to obtain the finished product.

Embodiment 4

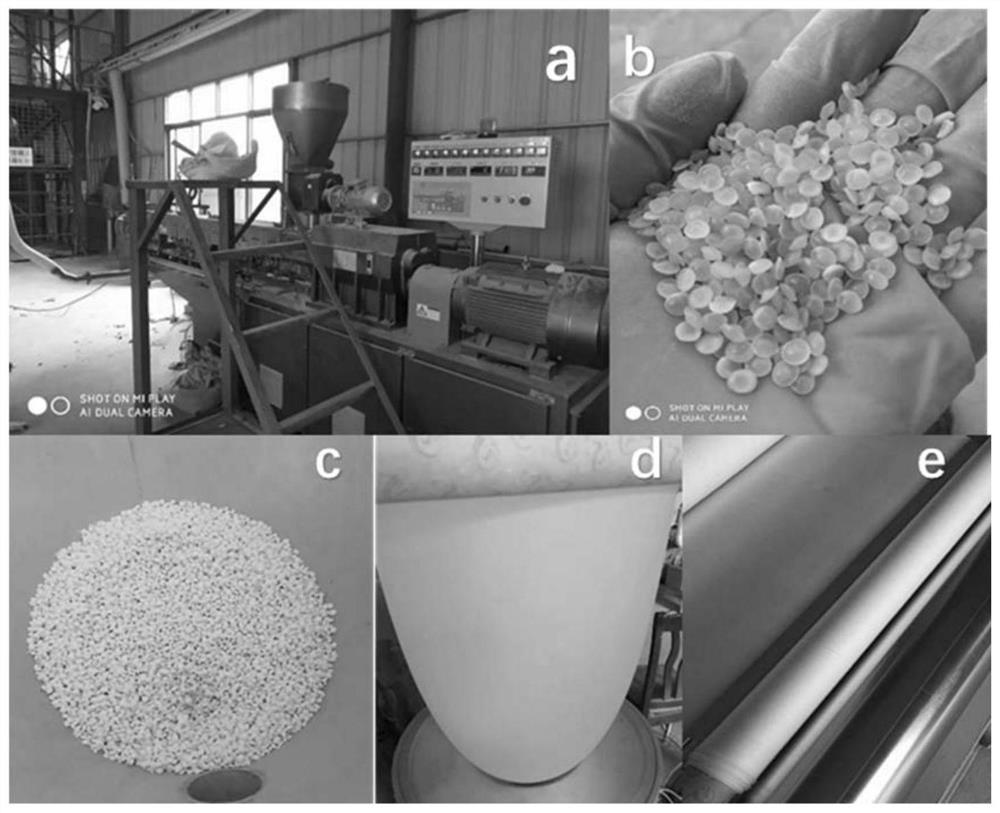

[0043] Example 4 The use effect and performance characterization of acid anhydride and epoxy polymer chain extension tackifier

[0044] 1. Experimental method

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com