Mesoporous coal series kaolinite energy storage phase change material and preparation method thereof

A technology of energy storage phase change and kaolinite, applied in the field of materials, can solve the problems of limited phase change materials and limited heat storage performance, and achieve excellent heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation:

[0045] 1. Preparation of mesoporous coal series kaolinite

[0046] (1) Organic modification: use dimethyl sulfoxide and water to prepare a dimethyl sulfoxide solution with a concentration of 90%, weigh a certain amount of coal-measure kaolinite and add it, and the coal-measure kaolinite and dimethyl The mass volume ratio of the sulfoxide solution is 1g:5ml; stir in a constant temperature water bath at 70°C for 24 hours; then centrifuge to remove the supernatant, and dry the obtained solid to obtain organically modified coal-measure kaolinite;

[0047] (2) Calcination: place the organically modified coal-series kaolinite in a muffle furnace at 850°C for 4 hours to obtain calcined activated partial coal-series kaolinite;

[0048] (3) Alkali activation: mix coal-series kaolinite with 4mol / L sodium hydroxide solution at a solid-to-liquid ratio of 1:20, and place it in a water bath at 80°C for 0.5h; after the reaction is completed, Centrifuge to remove waste...

Embodiment 2

[0058] Preparation:

[0059] 1. Preparation of mesoporous coal series kaolinite

[0060] (1) Organic modification: use dimethyl sulfoxide and water to prepare a dimethyl sulfoxide solution with a concentration of 85%, weigh a certain amount of coal-measure kaolinite and add it, and the coal-measure kaolinite and dimethyl The mass volume ratio of the sulfoxide solution is 1g: 3ml; stir in a constant temperature water bath at 65°C for 22 hours; then centrifuge to remove the supernatant, and dry the obtained solid to obtain organically modified coal-measure kaolinite;

[0061] (2) Calcination: place the organically modified coal-series kaolinite in a muffle furnace at 850°C for 4 hours to obtain calcined activated partial coal-series kaolinite;

[0062] (3) Alkali activation: mix coal-series kaolinite with 2mol / L sodium hydroxide solution at a solid-to-liquid ratio of 1:18, and place it in a water bath at 75°C for 0.3h with magnetic stirring; after the reaction is complete, Cen...

Embodiment 3

[0072] Preparation:

[0073] 1. Preparation of mesoporous coal series kaolinite

[0074] (1) Organic modification: use dimethyl sulfoxide and water to prepare a dimethyl sulfoxide solution with a concentration of 95%, weigh a certain amount of coal-measure kaolinite and add it, and the coal-measure kaolinite and dimethyl The mass volume ratio of the sulfoxide solution is 1g:8ml; stir in a constant temperature water bath at 75°C for 26 hours; then centrifuge to remove the supernatant, and dry the obtained solid to obtain organically modified coal-measure kaolinite;

[0075] (2) Calcination: place the organically modified coal-series kaolinite in a muffle furnace at 850°C for 4 hours to obtain calcined activated partial coal-series kaolinite;

[0076] (3) Alkali activation: mix coal-series kaolinite with 5mol / L sodium hydroxide solution at a solid-to-liquid ratio of 1:22, and place it in a water bath at 85°C for 0.8h; after the reaction is completed, Centrifuge to remove waste...

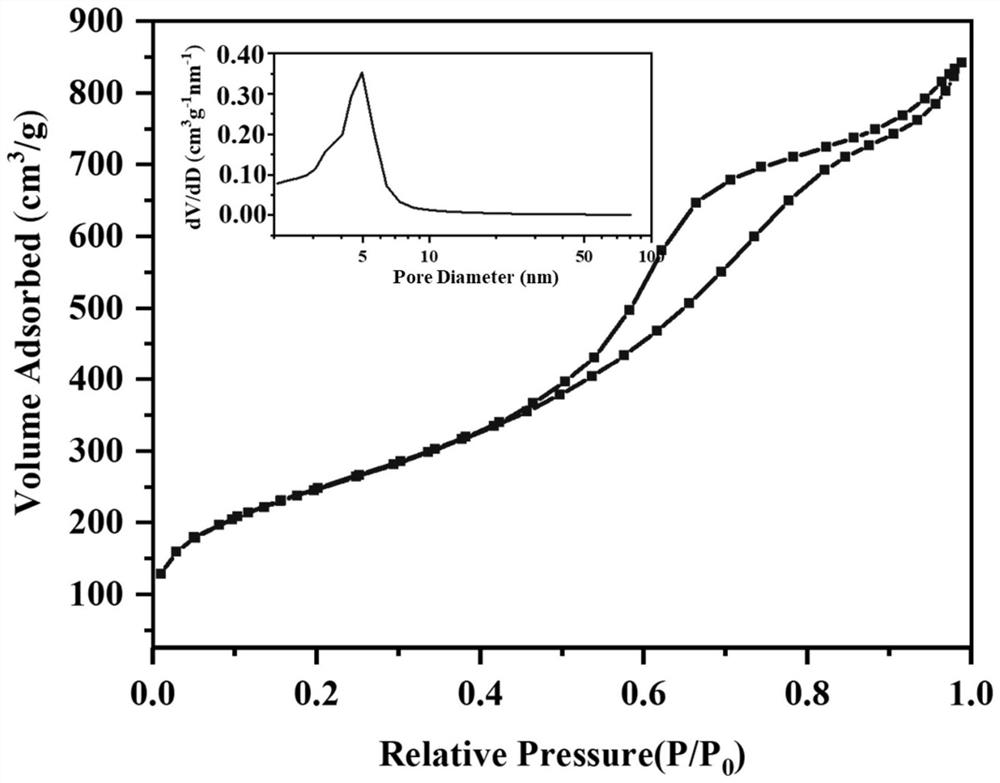

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com