Boron nitride-based flexible composite shaped phase change material film and preparation and application thereof

A phase change material, boron nitride-based technology, applied in applications, heat exchange materials, chemical instruments and methods, etc., can solve the problems of difficult to meet the application, leakage, reduced operability, etc., to achieve simple operation, low requirements, The effect of improving electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Take 0.3 g of boron nitride and a polyvinylidene fluoride solution (5wt%, the solvent of the polyvinylidene fluoride solution is methylpyrrolidone), and the mass ratio of boron nitride to polyvinylidene fluoride is 3:1. Magnetic stirring for 6h Mix evenly; then scrape the mixed solution into a boron nitride film of about 100um and place it in distilled water for 1 hour. Finally, place the film in a freeze dryer, set the temperature to -10 °C, and freeze dry for 48 hours to obtain boron nitride. Composite membrane carrier.

[0023] (2) Add an appropriate amount of paraffin (the mass ratio of paraffin to boron nitride film is 20:1) to the carrier in (1), place it in a vacuum oven, the degree of vacuum is -0.1MPa, and the temperature is 80°C for 3 hours of immersion . After removing the excess paraffin on the surface, a boron nitride-based flexible composite stereotyped phase change material film is finally obtained.

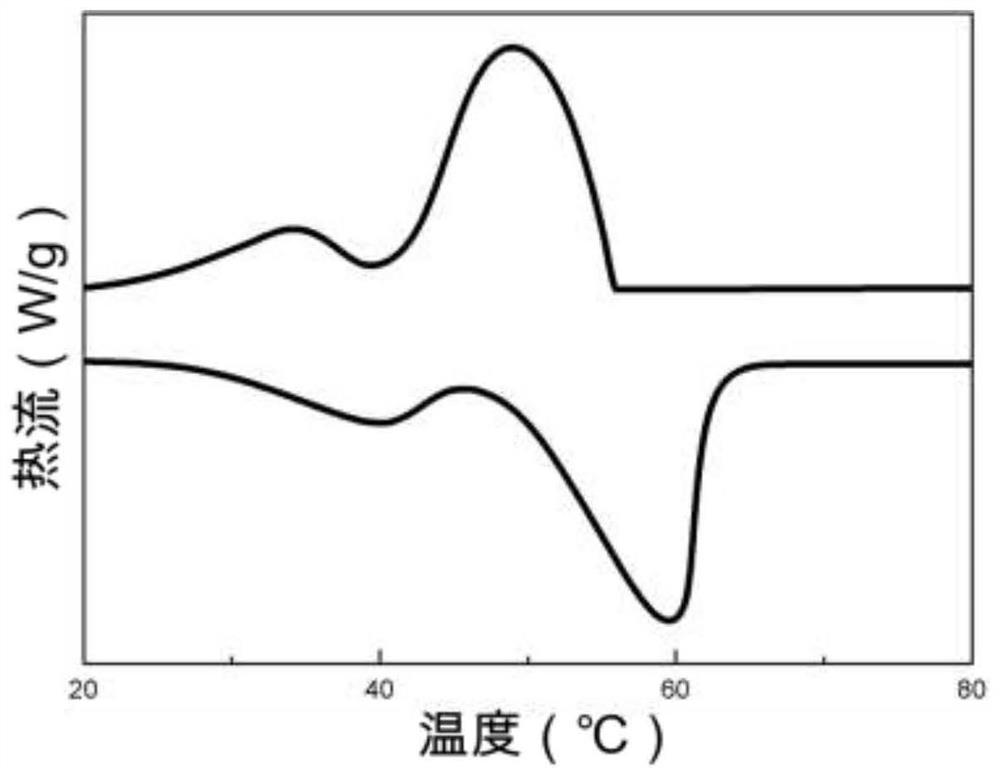

[0024] The boron nitride-based flexible composit...

Embodiment 2

[0026] (1) Take 0.3 g of boron nitride and polyvinylidene fluoride solution (6wt%, the solvent of polyvinylidene fluoride solution is methyl pyrrolidone), and the mass ratio of boron nitride aerogel to polyvinylidene fluoride is 1:1 Magnetic stirring for 5 hours to mix evenly; then the mixed solution was scraped into a boron nitride film of about 200um and replaced in distilled water for 1 hour. Finally, the film was placed in a freeze dryer, the temperature was set to -10 ° C, and freeze drying was obtained for 48 hours. Boron nitride composite membrane carrier.

[0027] (2) Add an appropriate amount of paraffin (the mass ratio of paraffin to boron nitride film is 20:1) to the carrier in (1), place it in a vacuum oven, the degree of vacuum is -0.1MPa, and the temperature is 80°C for 3 hours of immersion . After removing the excess paraffin on the surface, a boron nitride-based flexible composite stereotyped phase change material film is finally obtained.

[0028] The boron ...

Embodiment 3

[0030] (1) Take 0.3 g of boron nitride and polyvinylidene fluoride solution (10wt%, the solvent of polyvinylidene fluoride solution is methyl pyrrolidone), and the mass ratio of boron nitride aerogel to polyvinylidene fluoride is 2:1 Magnetic stirring for 7h to mix evenly; then the mixture was scraped into a boron nitride film of about 100um and replaced in distilled water for 1h, and finally the film was placed in a freeze dryer, the temperature was set to -10 ° C, and freeze-dried for 48h to obtain Boron nitride composite membrane carrier.

[0031] (2) Add an appropriate amount of octadecanoic acid (the mass ratio of octadecanoic acid to boron nitride film is 20:1) to the carrier in (1), place it in a vacuum oven, the degree of vacuum is -0.1MPa, and the temperature is 80 Immersion at ℃ for 3h. After removing the excess paraffin on the surface, a boron nitride-based flexible composite stereotyped phase change material film is finally obtained.

[0032] The boron nitride-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com