Hyperelastic guar gum carbon aerogel as well as preparation method and application thereof

A technology of guar gum carbon and carbon airgel, which is applied in the direction of airgel preparation, carbon preparation/purification, chemical instruments and methods, etc., can solve the problem that composite phase change materials are difficult to maintain shape stability, and achieve excellent thermal stability. The effects of cycle performance, high load capacity, and excellent heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation method of super elastic guar rubber carbon gas gel, including the following steps:

[0051] Step 1) Preparation of Guar Adhesive gels, 1 g of melamp powder added to a beaker of 100 ml of deionized aqueous solution, and the mechanical stirring 10 h is allowed to completely dissolve hydration, then, add 1 g of hydrogen phosphate, continued for the second stirring for 40 min, and the stirred defoaming was stored after stirring, and the frozen gel chip column was frozen in the refrigerator of -16 ° C, and then placed in the crystal dryer Dry 72H, can be obtained by melum / phosphate diommonium hydrogel;

[0052] Step 2) Preparation of super-elastic guar rubber carbon gas gel, first place step 1 to be placed in a blast drying tank for two-step heat treatment, the first step heat treatment is processed at 120 ° C for 6 h The second step heat treatment is, increase the temperature to 180 ° C, continuous treatment for 6 h, after the two step heat treatment is completed,...

Embodiment 2

[0067] This embodiment provides a method of preparing a super elastic guar rubber carbon gas gel. The steps not specifically described are the same as in Example 1. Different in: The mass of dismine ammonium hydrogen phosphate is 0.5 g, The resulting sample was named SCA-0.5.

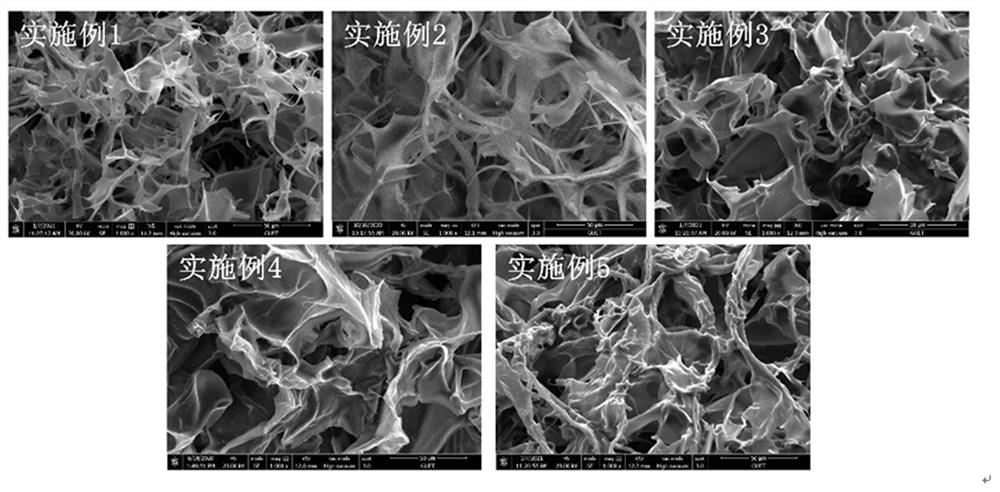

[0068] In order to demonstrate the addition of phosphate ammonium hydrogen phosphate to the microstructure of super-elastic guar rubber gas gel, SCA-0.5 is carried out, and the results are figure 1 As shown, SCA-0.5 has a complete cross-linking three-dimensional network structure, but in conjunction with SCA-1 in Example 1, the aperture structure is too much disadvantageous to attach to-in-cell phase change medium, mainly because of the addition of phosphate. At small, its hydrogen bonding between the GG molecules is weak such that the arrangement between the GG molecular chains is not compact, and thus the prepared carbon gas gel structure is loose, and the aperture structure is too large.

[0069] In orde...

Embodiment 3

[0071] This embodiment provides a method of preparing a super elastic guar rubber carbon gas gel, and the step of not particularly explained is the same as in Example 1, and the mass of the addition of phosphate in the step 1 is 1.5 g, The resulting sample is named SCA-1.5.

[0072] In order to demonstrate the amount of phosphate amonium hydrogen phosphate to the microstructure of super-elastic guar rubber gas gel, SCA-1.5 has been subjected to SCA-1.5. figure 1 As shown, some aggregation phenomena in the SCA-1.5 carbon gas gel structure compared to in Example 1, and the hole structure also exhibits a slight contraction collapse.

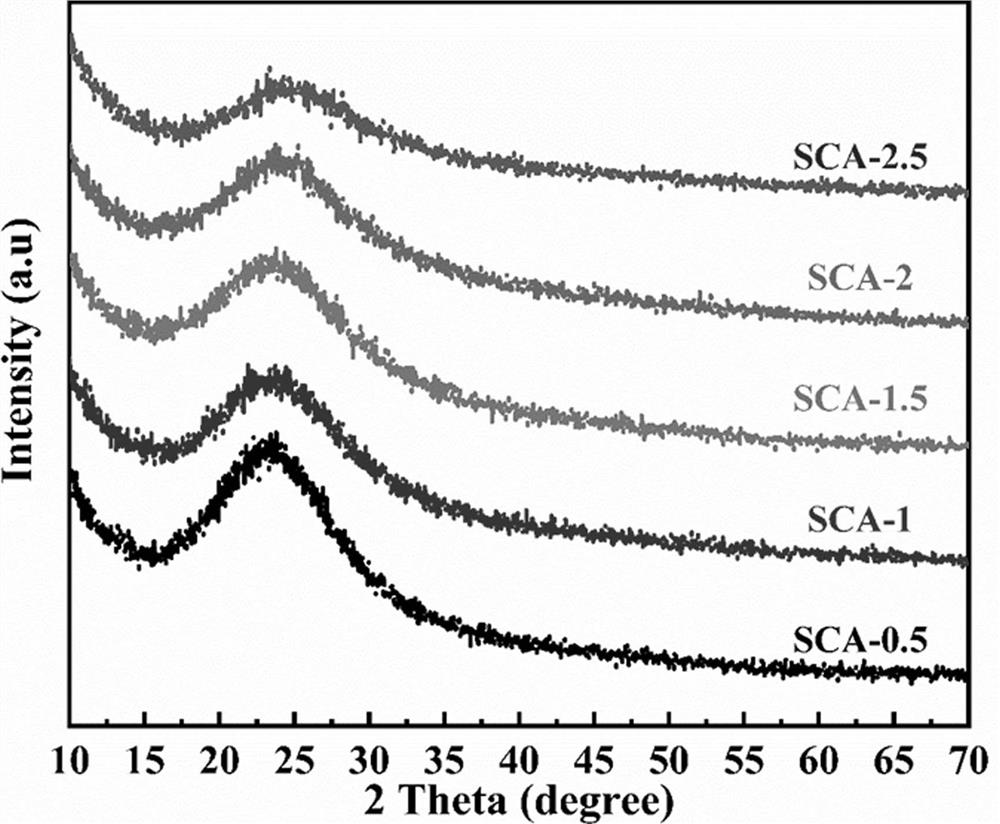

[0073] In order to demonstrate the addition of phosphate anexide to the crystallization properties of super-elastic guar rubber gas gel, XRD testing is performed on SCA-1.5. figure 2 As shown, the XRD map shows a pattern similar to the SCA-1 in Example 1, but the half peak width is wider, since the increase in the amount of the hydrogen phosphate added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com