Coupling method for improving tracking error of optical device with refrigeration function

A tracking error and optical device technology, applied in the coupling of optical waveguides, optical components, light guides, etc., can solve the problems of large performance differences, increased power consumption, and large differences in product power consumption, achieving small performance differences and improved tracking Good effect of error and product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

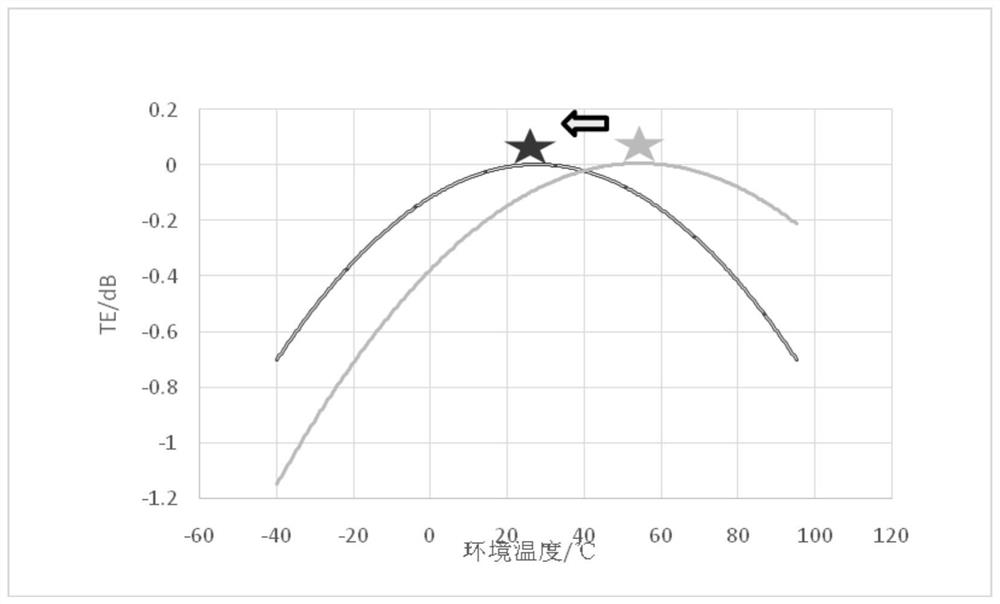

[0030] Such as image 3 As shown, the method of the present invention is used to ameliorate the problem of large TE. The gray line curve indicates that the TE is very poor at low temperature, reaching -1.2dB. It can be seen that the TE at low temperature is much larger than that at high temperature, which means that the focal length changes greatly at high and low temperatures. The purpose of the present invention is to adjust the temperature & TE curve into a black double line curve.

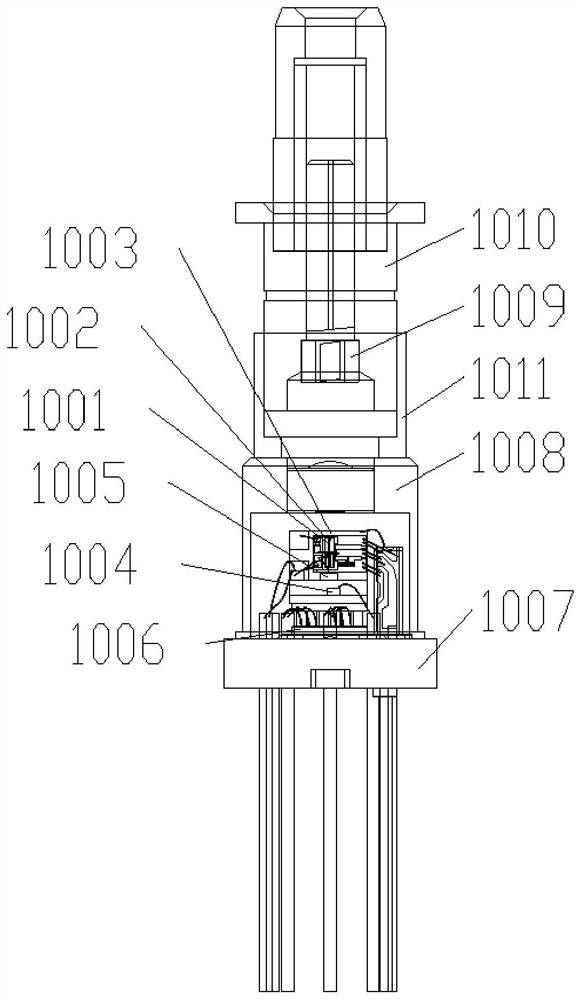

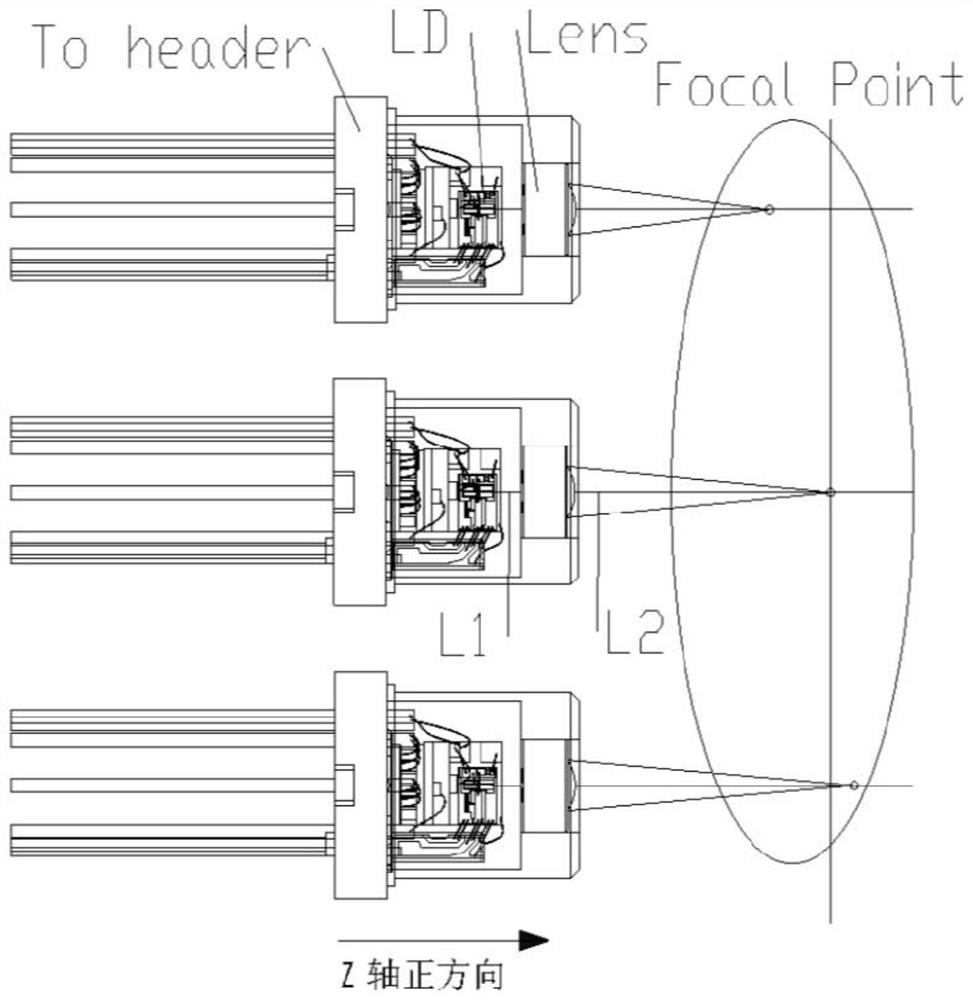

[0031] Through a large number of experiments and optical simulations, it is found that it is necessary to balance the focal length of the optical coupling between the adapter and the TO socket, that is, it is not conventional to couple to the maximum value and then fix it by laser welding, and to make an offset in the Z-axis direction after the maximum couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com