Side extrusion forming method of parking gear tooth profile

A parking gear, extrusion molding technology, applied in the field of auto parts processing, can solve the problems of reducing product quality, one-sided flow, affecting the accuracy of parts, etc., and achieves improved mechanical performance indicators, good internal organization of metal, and easy tooth shape. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described below with reference to the accompanying drawings and embodiments.

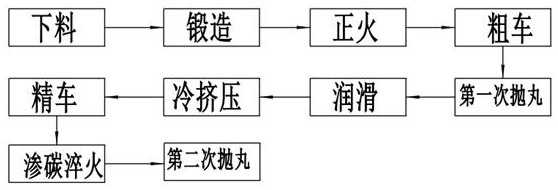

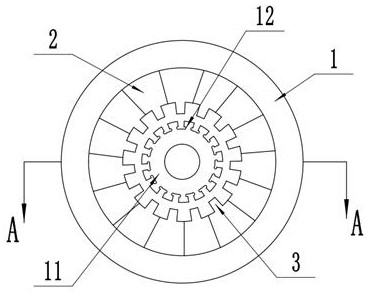

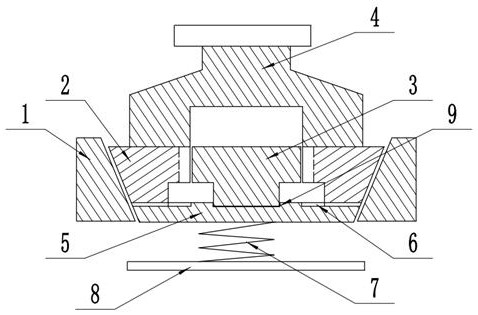

[0037] This example: see Figure 1-Figure 5 , The lateral extrusion forming method of the tooth profile of the parking gear, including the sequential blanking, forging, normalizing, rough turning, first shot blasting, lubrication, cold extrusion, finishing turning, carburizing and quenching process and the second time In the shot blasting process, the forging process forges the blanked material to initially form the rectangular teeth of the parking gear, and obtains a prefabricated blank 11 with recessed grooves 12 formed on both sides of the tooth root of the rectangular tooth; The prefabricated blank 11 processed by the process is placed in a cold extrusion die for extrusion at room temperature. The cold extrusion die includes a plurality of mutually matched movable modules 2 evenly arranged in the circumferential direction. In the annular annular cavity where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com