Textile yarn bobbin manufacturing and processing machine

A technology for processing machinery and textile yarns, which is applied in the field of textile yarns, and can solve the problems affecting the grinding of yarn tubes, reducing the efficiency of grinding, increasing the workload of operators, etc., and achieving the effect of reducing wear and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention is further elaborated.

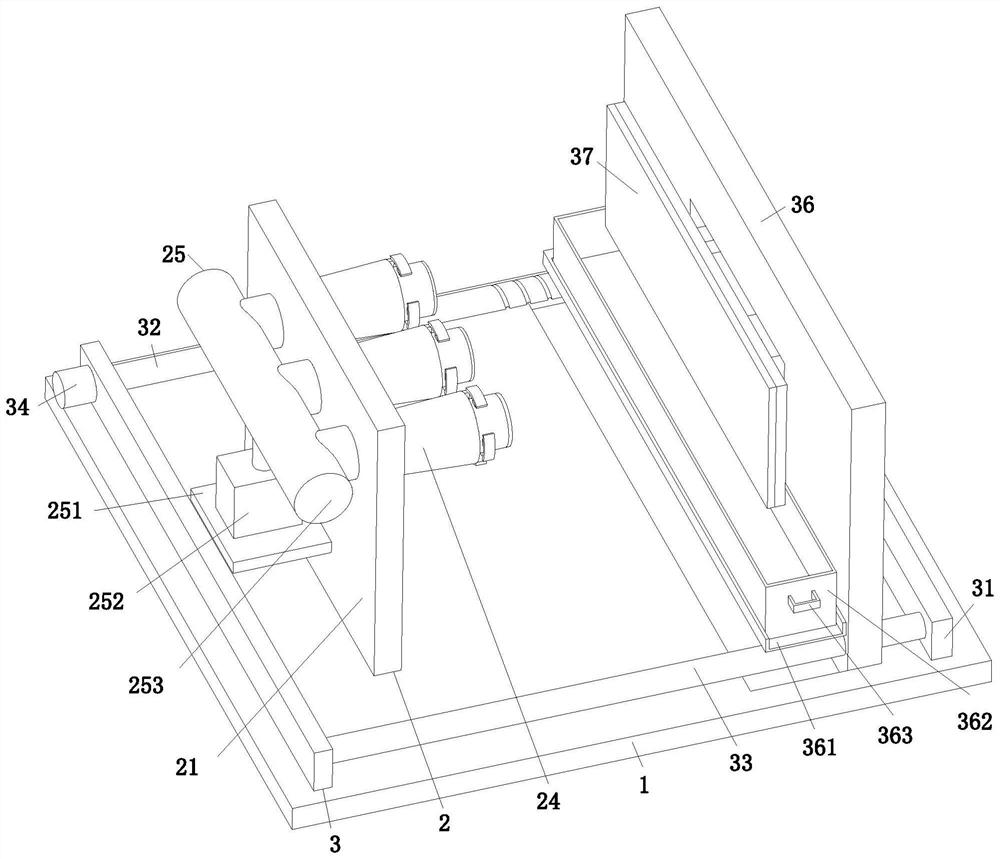

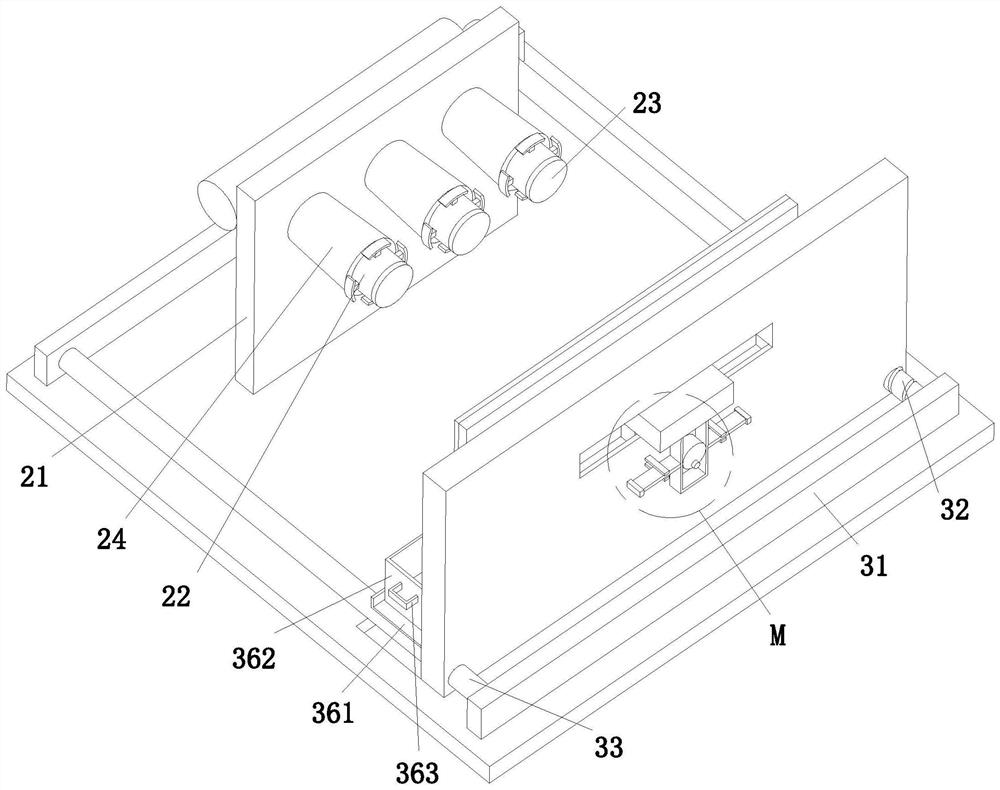

[0031] refer to figure 1 and figure 2 , a textile yarn bobbin manufacturing and processing machine, comprising a workbench 1, a fixing device 2 and a grinding device 3, the top of the workbench 1 is provided with a fixing device 2 and a grinding device 3;

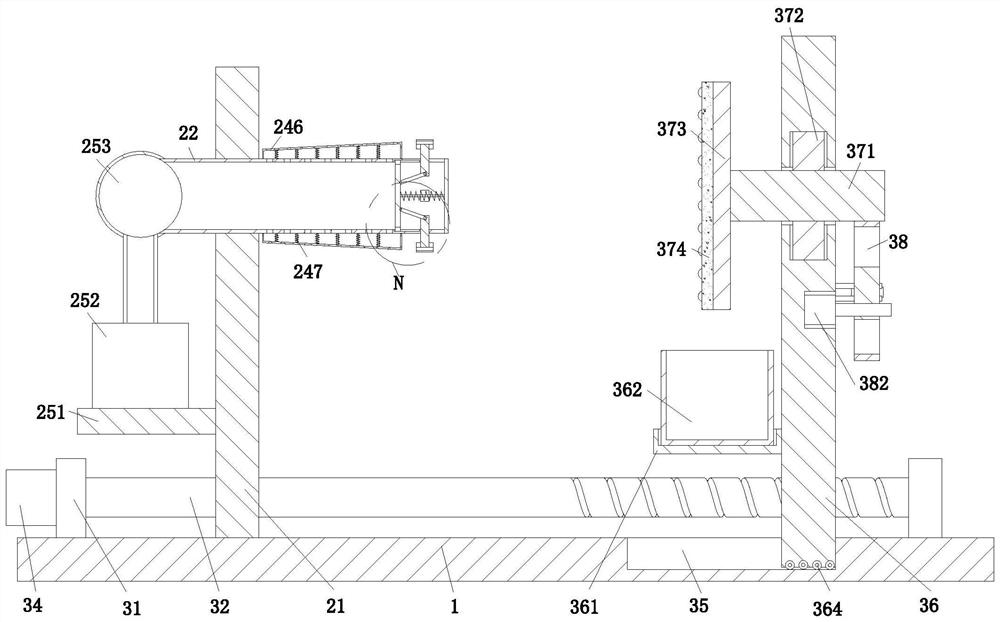

[0032] refer to figure 1 , figure 2 and image 3 , the fixing device 2 includes a fixing structure plate 21, a hollow tube 22, a circular plate 23, a clamping frame 24 and a fixing frame 25, and a fixing structure is fixedly installed on the upper end surface of the workbench 1 near the left side Plate 21, the side wall of the fixed structure plate 21 is evenly opened with a No. 1 circular channel from front to back, and a hollow cylinder 22 is fixedly installed in the No. 1 circular channel, and the right end of the hollow tube 22 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com