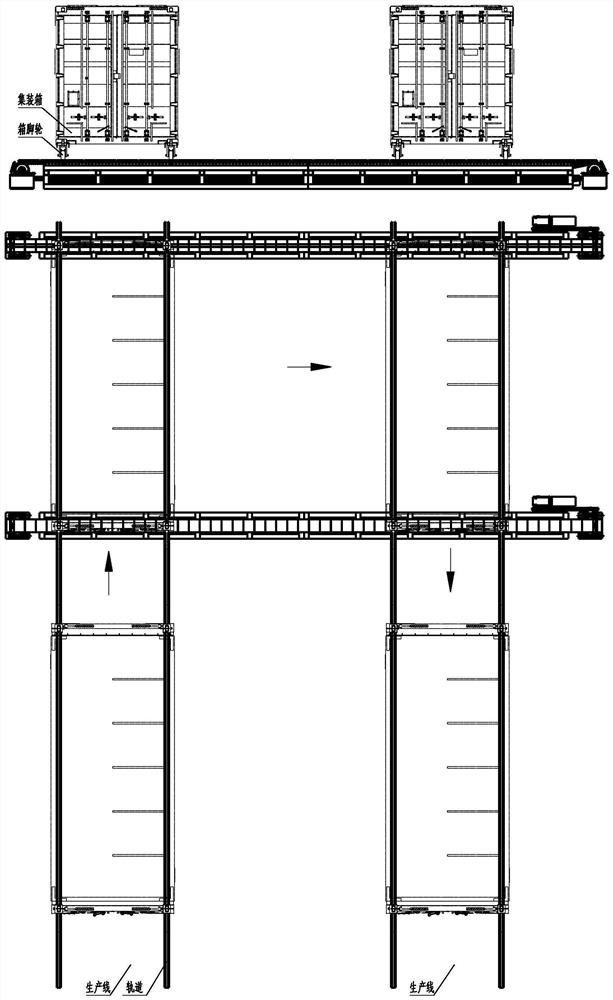

Container transverse-moving sequence transfer device

A container and shaft technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as not being able to meet production needs, achieve the effects of shortening the sequence time, reducing production costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

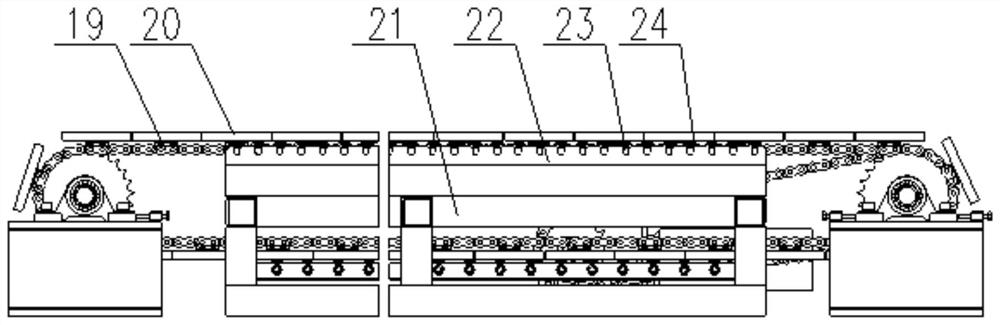

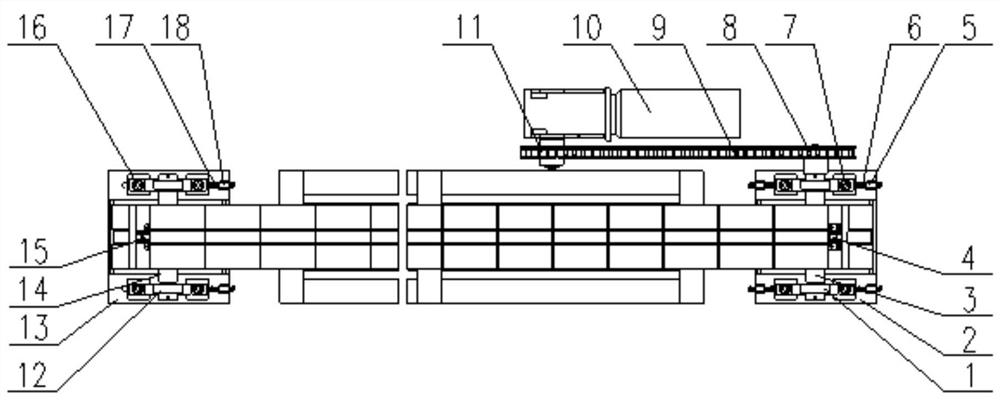

[0017] exist Figure 1 to Figure 3 In the schematic diagram of the present invention shown, the active mechanism includes an active support, a bearing seat A, a rotating shaft A, a sprocket A, a sprocket B, a sprocket C, a chain A, a nut A, a jacking screw A and a bolt a. The two bearing seats A1 are placed on the active support 2, and the two bearing seats A are connected by the rotating shaft A3, and the sprocket A4 is sleeved on the rotating shaft A, and one end of the rotating shaft A extends to the outside of the bearing seat A, and the rotating shaft A Sleeve sprocket B8 on one end. The output end of the motor 10 is provided with a sprocket C11, and the sprocket C and the sprocket B are connected by a chain A9. There is a screw nut A5 on the active support, and a jacking screw A6 is inserted into the nut A, and one end of the jacking screw A can be extended and inserted into the bearing seat A, and the bearing seat is fixed by the bolt A7 on the bearing seat A A is at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com