Water treatment equipment and water treatment system

A technology for water treatment equipment and water outlet area, which is applied in multi-stage water treatment, water treatment parameter control, biological water/sewage treatment, etc., and can solve problems such as large occupied area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

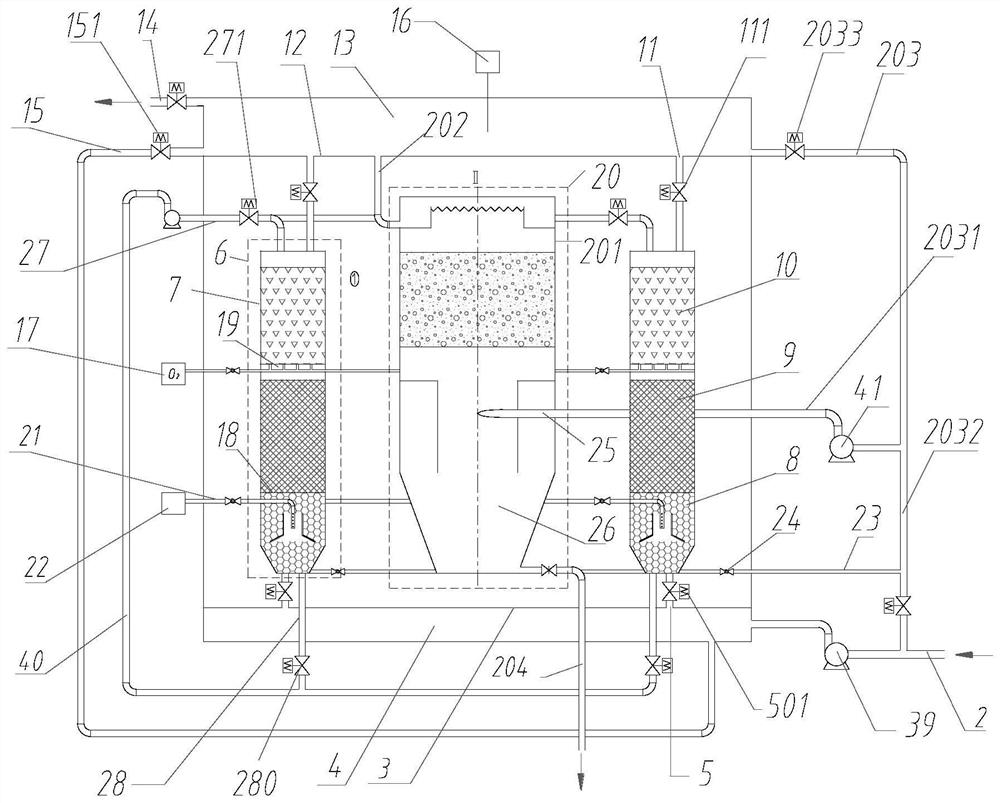

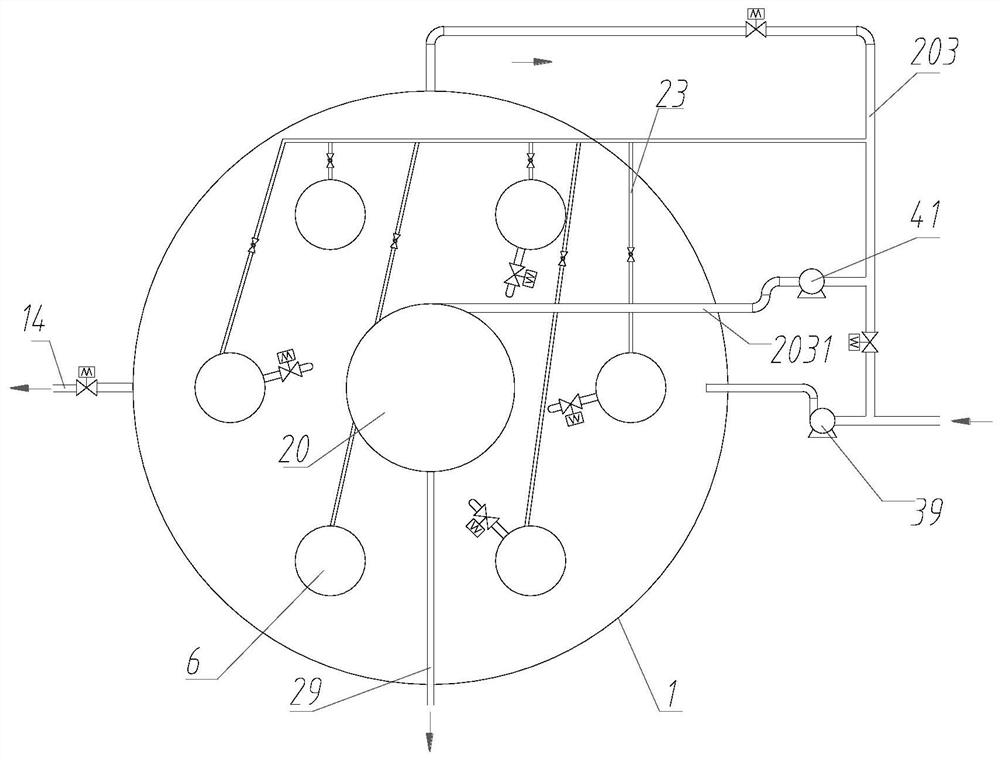

[0039] This embodiment provides a kind of water treatment equipment, such as figure 1 with figure 2 shown, including:

[0040] The housing 1 is provided with an accommodating chamber inside;

[0041] Specifically, the casing 1 itself is configured in a cylindrical shape, and an accommodating cavity is arranged inside. From the material point of view, the housing 1 itself is made of metal materials such as stainless steel.

[0042] The main water inlet pipe 2 is connected with the housing 1;

[0043] Specifically, the main water inlet pipe 2 itself is connected to the sewage source, and the external sewage can be introduced into the interior of the entire water treatment equipment through the main water inlet pipe 2 for purification operation. Simultaneously, in order to improve the water inlet water pressure, a water inlet pump 39 is provided on the water inlet main pipe 2 .

[0044] The first partition 3 is arranged in the accommodating chamber, and a water inlet area 4...

Embodiment 2

[0099] The present embodiment provides a water treatment system, comprising:

[0100] sewage source;

[0101] Specifically, there is no limitation on the source of the sewage source, which may be a sewage tank or a sewage pipe, as long as it is a structure that can realize the sewage injection operation.

[0102] In the water treatment equipment provided in embodiment 1, the water inlet main pipe is arranged downstream of the sewage source;

[0103] The sewage flowing in through the sewage source is treated and purified in the water treatment equipment. In this embodiment, for the sewage with relatively low carbon and nitrogen, the water treatment equipment can realize various functions such as biological nitrification, denitrification phosphorus removal, SS interception, etc. , can complete simultaneous denitrification, dephosphorization and SS removal. In addition, the small footprint of the water treatment equipment itself can make the footprint of the entire water treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com