Method for continuously synthesizing perchloromethyl mercaptan by using reaction tower

A technology of perchloromethane mercaptan and reaction tower, which is applied in mercaptan preparation, organic chemistry and other directions, can solve the problems of back-mixing and by-products, low raw material utilization rate and production efficiency, low safety, etc., so as to improve reaction safety. Controllability and controllability, improve the low utilization rate of raw materials, and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

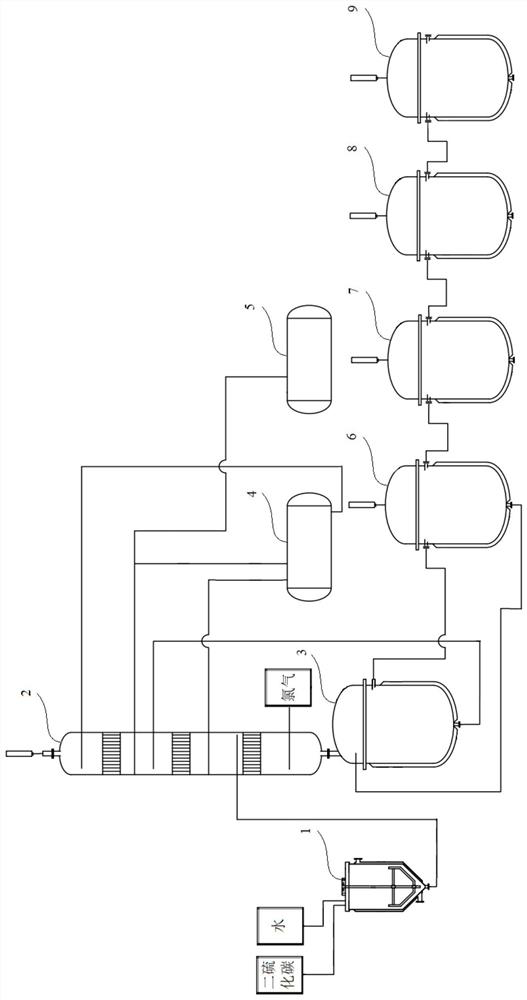

Image

Examples

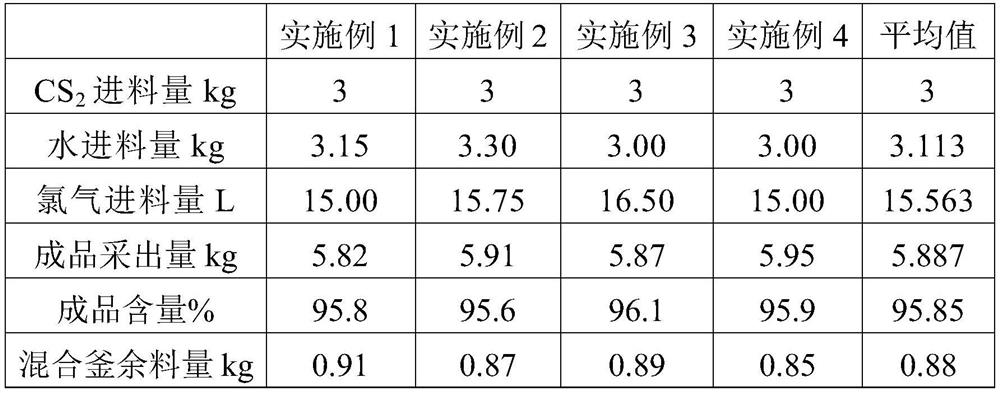

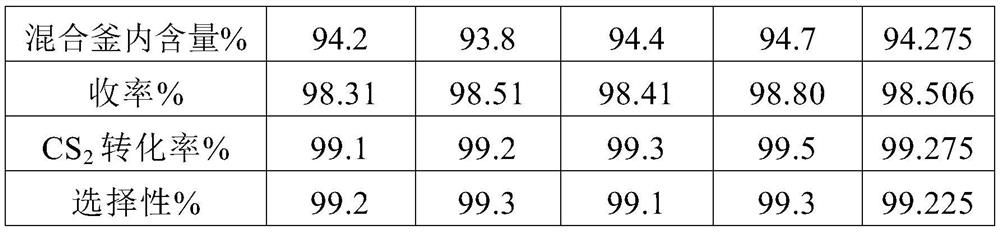

Embodiment 1

[0047] Utilize the method for continuous synthesis of perchloromethanethiol in reaction tower, may further comprise the steps:

[0048] 1) Put carbon disulfide and water with a mass ratio of 1:1.05 into the blending kettle in proportion, after stirring and mixing, cool down to 10°C; the amount of material in the blending kettle is 82.5wt% of the total amount of carbon disulfide and water;

[0049] 2) Mix the remaining carbon disulfide and water evenly at a mass ratio of 1:1.05. After cooling down to 10°C, send the mixed solution to the mixing tank at the bottom of the reaction tower, and use a quantitative pump to feed the mixed solution at a rate of 0.8 L / min. The material flow rate is pumped into the feed inlet of the first layer of the reaction tower, the mixed liquid is dispersed through the distributor, and then chlorine gas is introduced at a flow rate of 5L / min, and the temperature in the reaction tower is controlled not to exceed 35°C, and the reacted reaction liquid is...

Embodiment 2

[0057] Utilize the method for continuous synthesis of perchloromethanethiol in reaction tower, may further comprise the steps:

[0058] 1) put carbon disulfide and water with a mass ratio of 1:1.1 into the blending kettle in proportion, after stirring and mixing, cool down to 10°C; the amount of material in the blending kettle is 85wt% of the total amount of carbon disulfide and water;

[0059] 2) Mix the remaining carbon disulfide and water evenly at a mass ratio of 1:1.1. After cooling down to 10°C, send the mixed solution to the mixing tank at the bottom of the reaction tower, and use a quantitative pump to feed the mixed solution at a rate of 1.0L / min. The material flow rate is pumped into the feed inlet of the first layer of the reaction tower, the mixed liquid is dispersed through the distributor, and then chlorine gas is introduced at a flow rate of 6L / min, and the temperature in the reaction tower is controlled not to exceed 35°C. After the reaction, the reaction liquid...

Embodiment 3

[0067] Utilize the method for continuous synthesis of perchloromethanethiol in reaction tower, may further comprise the steps:

[0068] 1) Put carbon disulfide and water with a mass ratio of 1:1 into the blending kettle in proportion, after stirring and mixing, cool down to 10°C; the amount of material in the blending kettle is 80wt% of the total amount of carbon disulfide and water;

[0069] 2) Mix the remaining carbon disulfide and water evenly at a mass ratio of 1:1. After cooling down to 10°C, send the mixed solution to the mixing tank at the bottom of the reaction tower, and use a quantitative pump to feed the mixed solution at a rate of 1.2L / min. The material flow rate is pumped into the feed inlet of the first layer of the reaction tower, the mixed liquid is dispersed through the distributor, and then chlorine gas is introduced at a flow rate of 7L / min, and the temperature in the reaction tower is controlled not to exceed 35°C. The reacted reaction liquid is sent into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com