Annular laser cladding nozzle

A laser cladding and nozzle technology, which is applied in the coating process and coating of metal materials, can solve the problems of complex operation, complex processing procedures, uneven powder feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

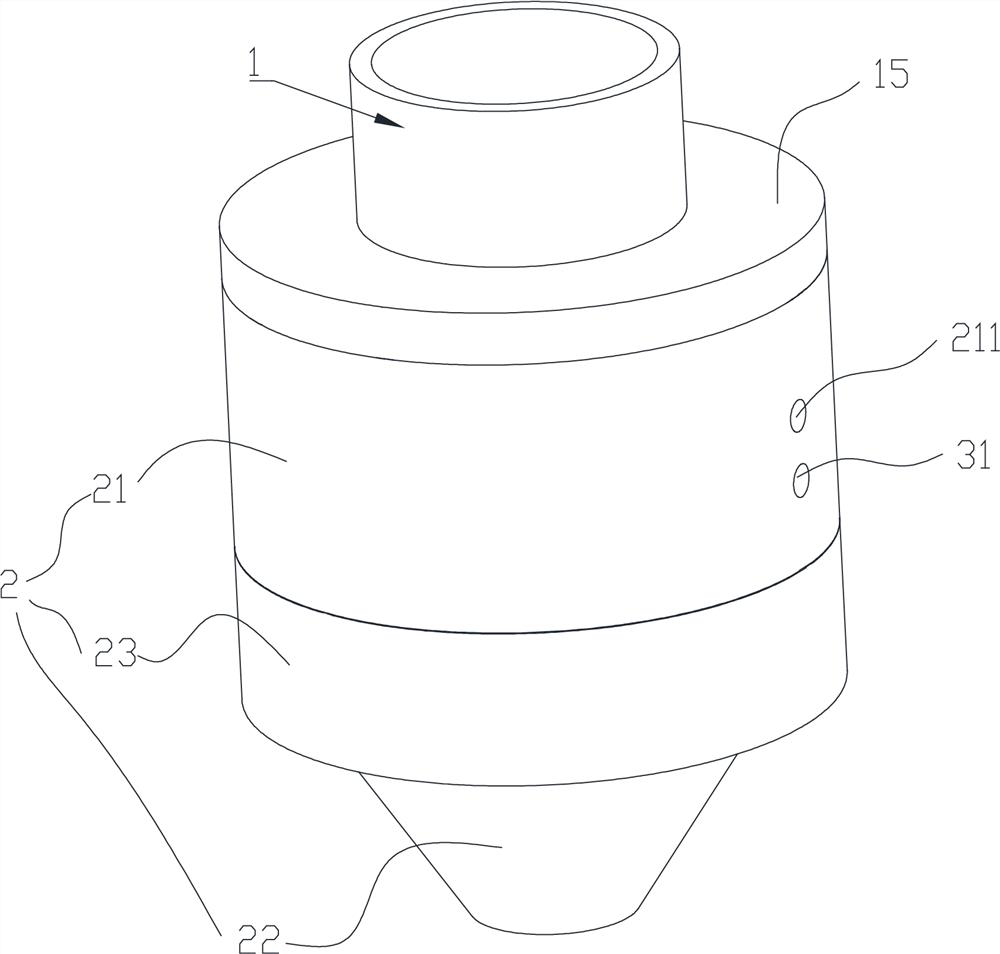

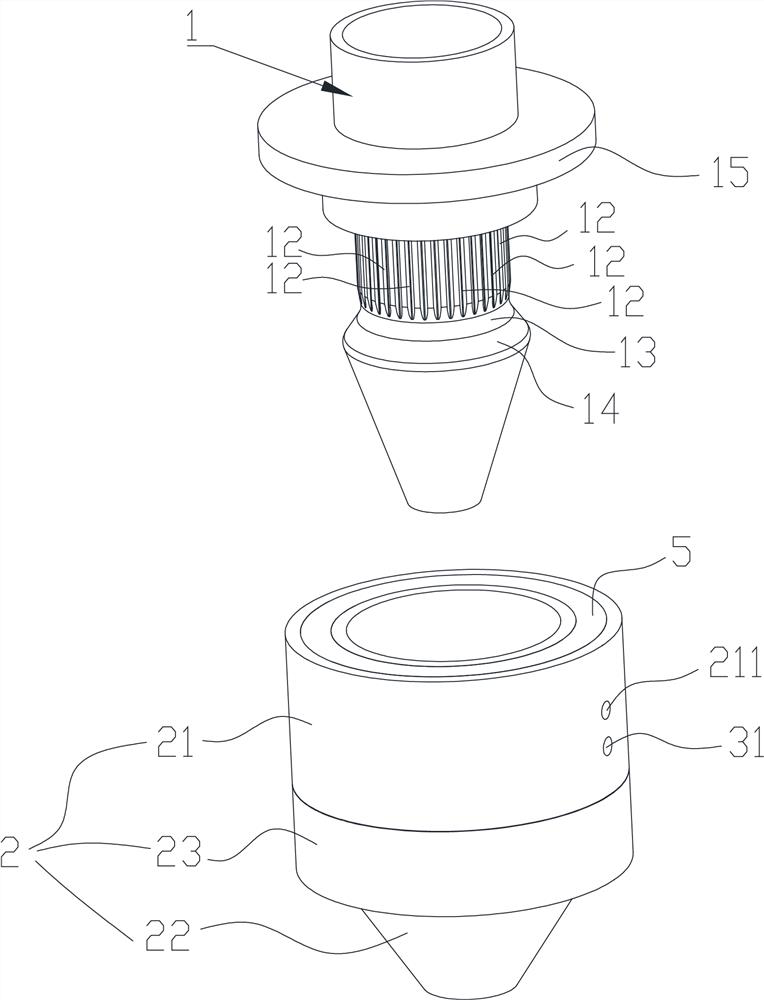

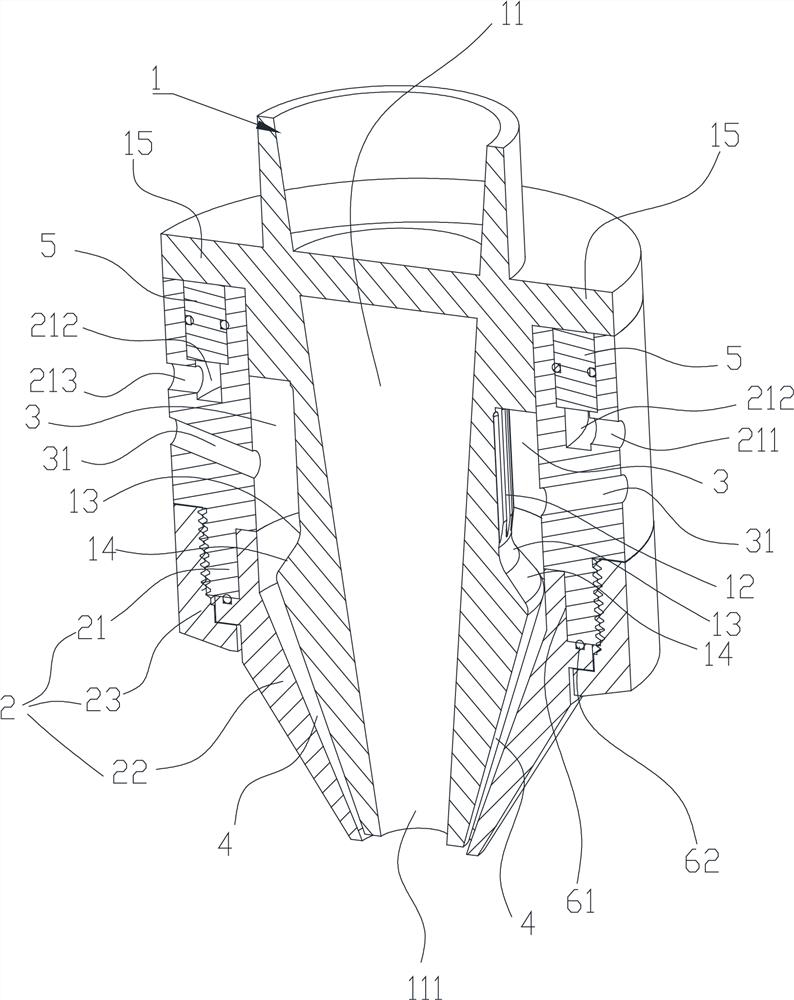

[0031] Figure 1 to Figure 7 It is a structural schematic diagram of the present invention.

[0032] The reference signs therein are: inner core 1, outer jacket 2, laser channel 11, opening 111, mixing chamber 3, second conveying channel 4, first conveying channel 31, groove 12, slope surface 14, circular arc depression 13 , coolant flow channel 212, liquid injection port 211, liquid discharge port 213, ring protrusion 15, processing groove 214, first seal 5, channel part 21, cone head part 22, concave-convex matching structure 61, second seal Part 62, the outer ring fixing sleeve 23, the first stepped surface 221, and the second stepped surface 231.

[0033] Figure 1 to Figure 7 It is a schematic diagram of the structure of the present invention. The "tail end" referred to in this embodiment refers to the end in the same direction as the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com