Site-limited long-distance large-aperture horizontal directional drilling pipeline back-dragging construction process

A technology of horizontal directional drilling and horizontal directional drilling rig, which is applied in the directions of directional drilling, drilling pipe, pipeline laying and maintenance, etc., can solve the problem of inability to prefabricate the dragging pipe, increasing the risk of directional drilling collapse and shrinking, and the construction of dragging the pipe. difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

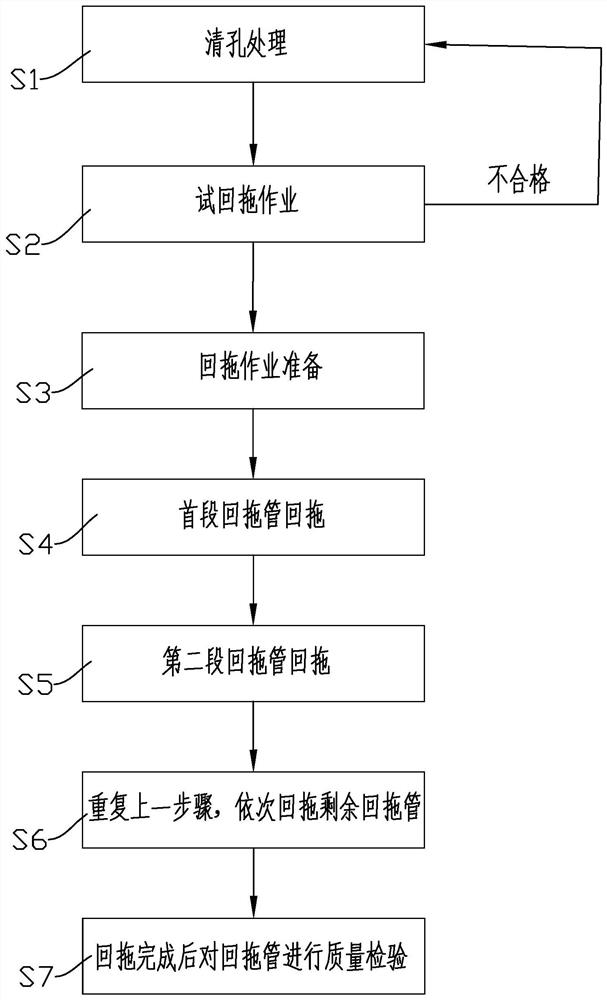

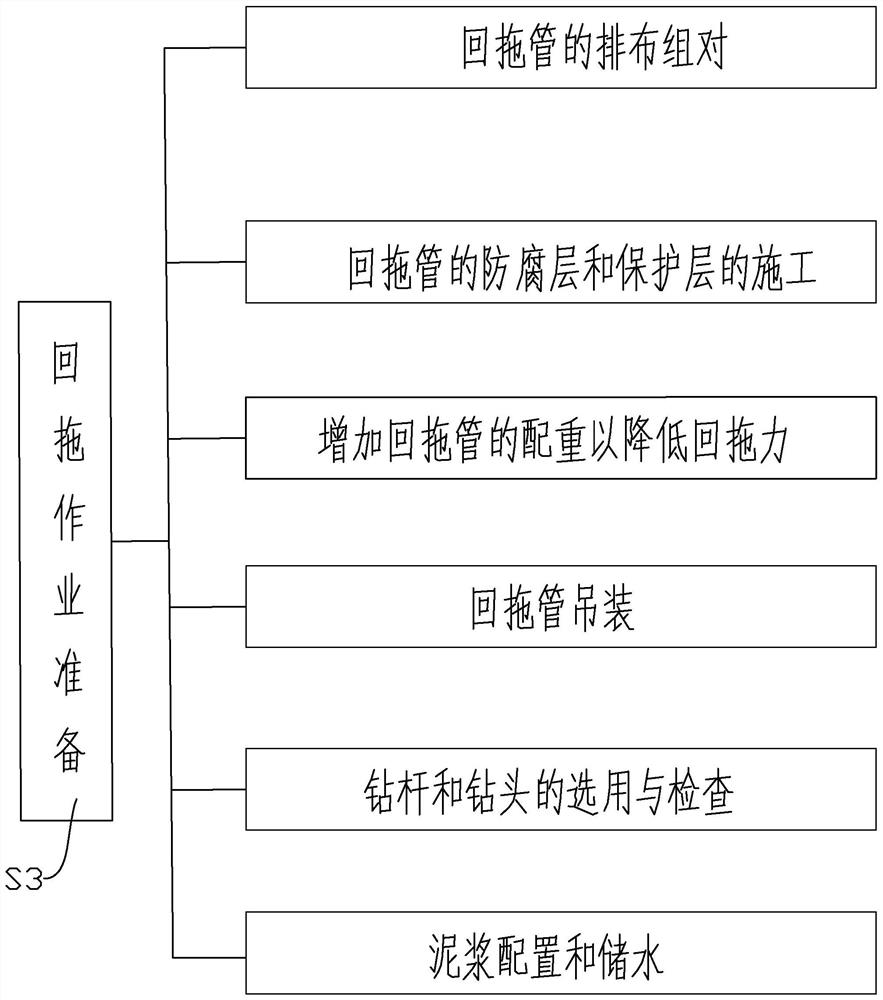

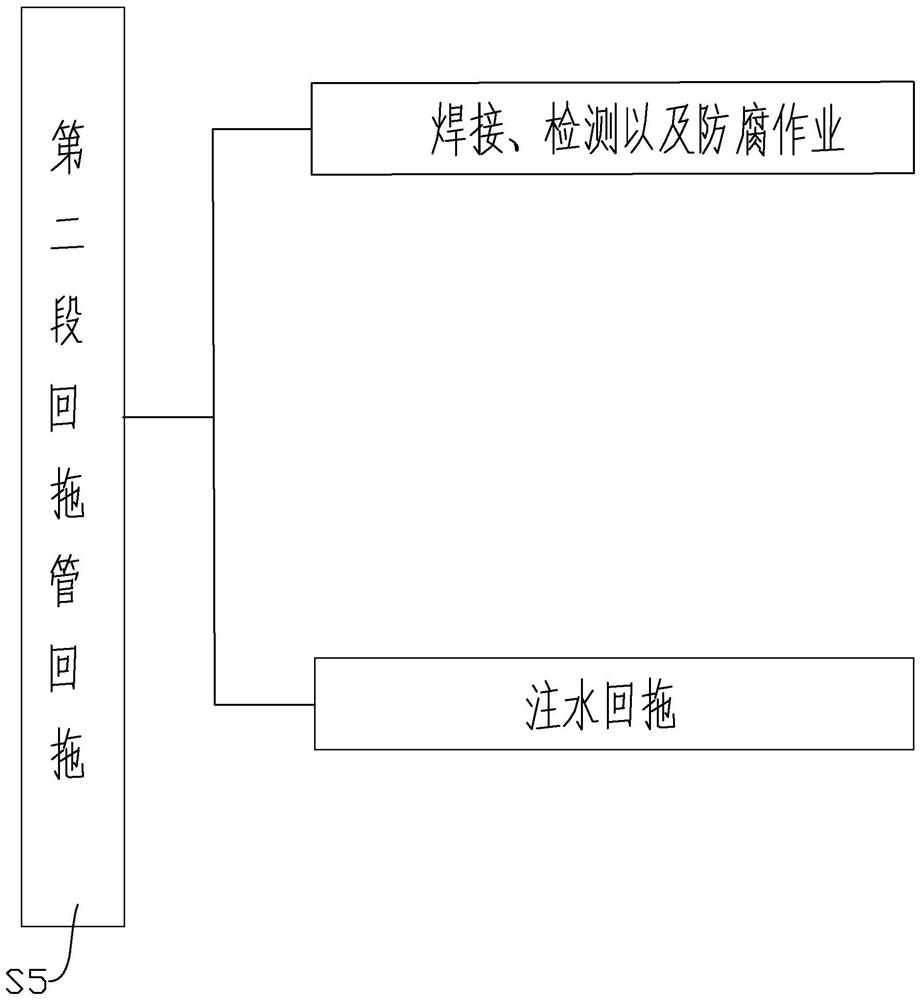

[0061] The following is attached Figure 1-5 The application is described in further detail.

[0062] The embodiment of the present application discloses a long-distance large-aperture horizontal directional drilling pipeline pull-back construction process with limited space. refer to figure 1 , the site-limited long-distance large-aperture horizontal directional drilling pipeline pull-back construction process includes the following steps:

[0063] S1. Hole cleaning treatment: the operator first places a drill bit on the ground on the side of the guiding out-drilling point 42, and then installs the horizontal directional drilling machine 2 on the ground on the side of the guiding-in drilling point 41. The horizontal directional drilling machine 2 is detachably connected with a plurality of successively connected drill pipes 31, the drill pipe 31 closest to the end leading out of the drilling point 42 is the first drill pipe 31, and the end of the first drill pipe 31 away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com