Airflow suspension movement assembly for high-speed turbine dental handpiece and dental handpiece

A technology for dental handpieces and turbine components, used in dentistry, dental drilling, medical science, etc., can solve the problems of low power loss, low calorific value, and high rotational speed, and achieve low power loss, low calorific value, and high rotational speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

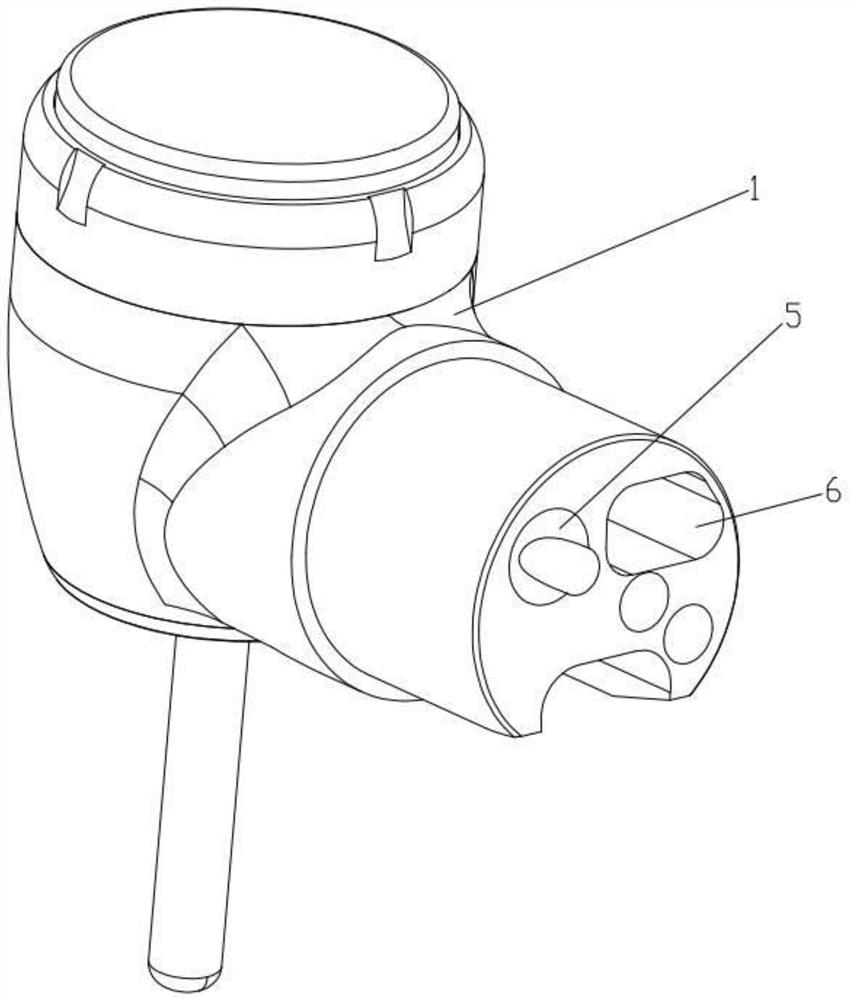

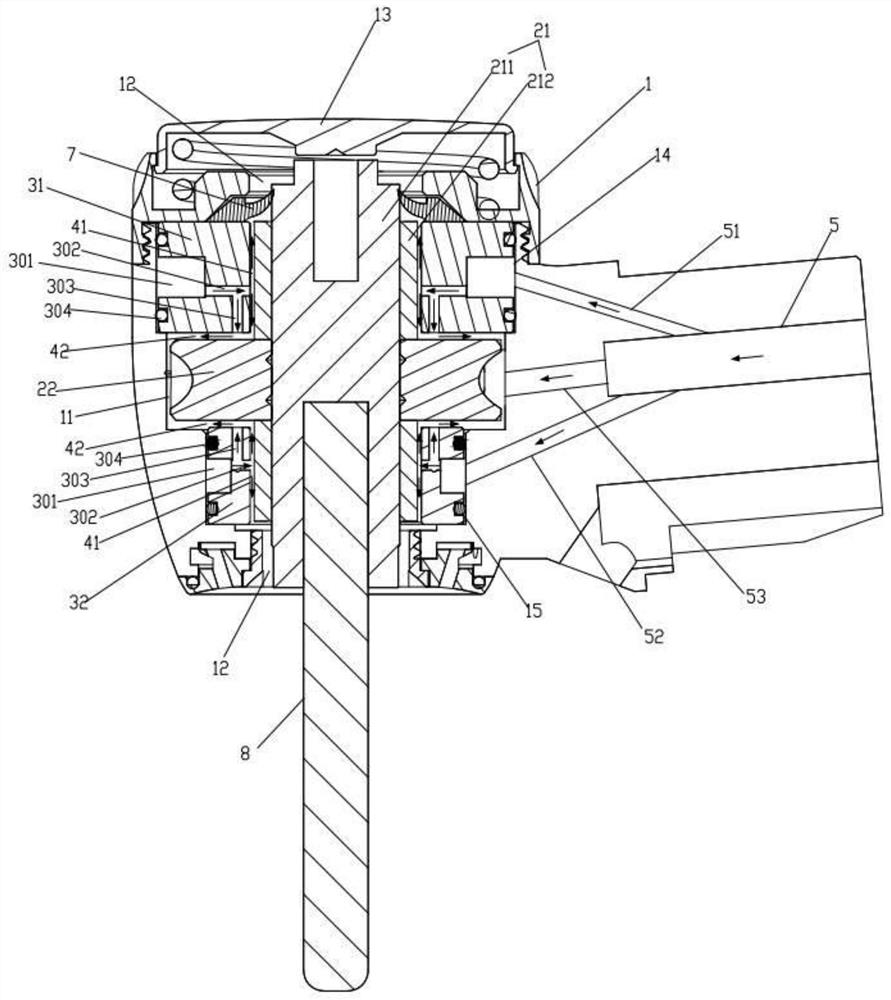

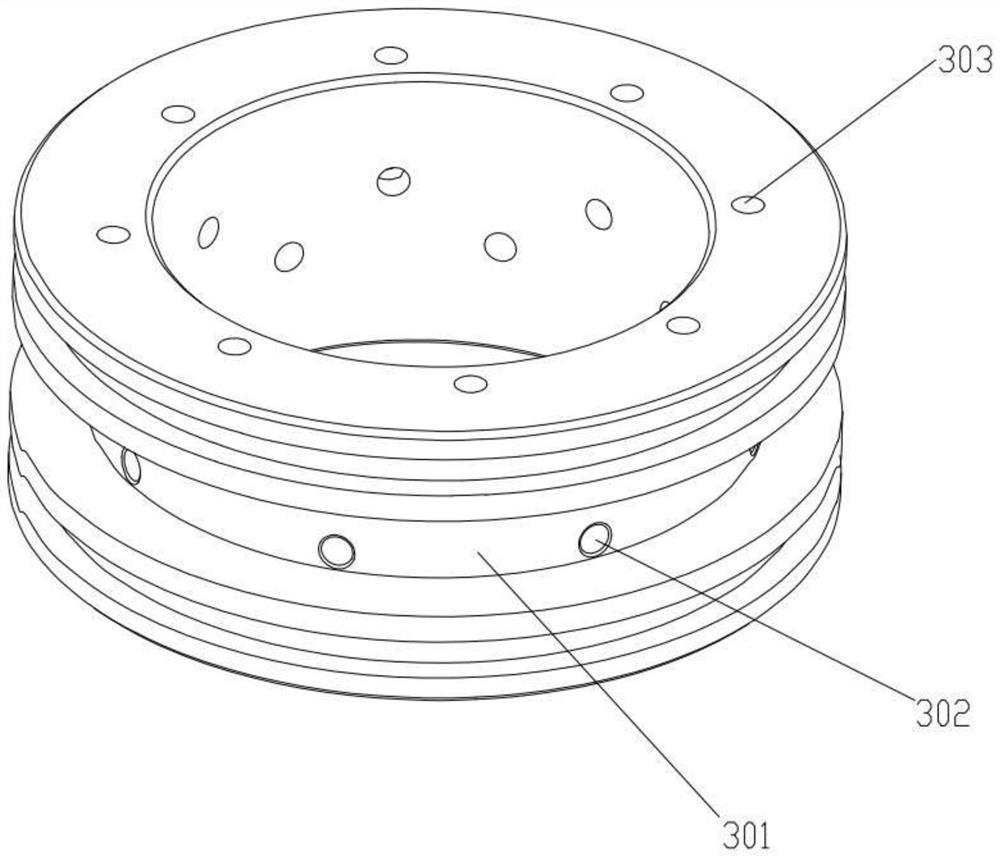

[0026] Such as Figure 1-3As shown, the air-suspension core assembly for high-speed turbine dental handpieces includes a handpiece housing 1, a turbine assembly rotatably arranged in the handpiece housing 1, and a bearing for supporting the turbine assembly. The turbine assembly includes a rotating shaft 21 and the turbine 22 fixedly sleeved outside the rotating shaft 21, the turbine 22 is placed in the turbine cavity 11 in the head housing 1, the rotating shaft 21 includes a shaft 211 and two steel sleeves fixedly sleeved outside the shaft 211 A barrel 212, the lower end of the shaft is used to connect the bur 8, two sleeves 212 are arranged at intervals along the axial direction and are respectively located at the upper and lower ends of the turbine 22, and the bearings include axial intervals arranged at the upper and lower ends of the turbine 22. The upper bushing 31 and the lower bushing 32 at both ends, the upper bushing 31 and the lower bushing 32 are all fixed in the m...

Embodiment 2

[0032] Such as Figure 4 As shown, a dental handpiece 100 includes a handle 20 and a handpiece 10 installed at one end of the handle 20 , the handpiece includes the air suspension core assembly in Embodiment 1. Since the performance, service life, manufacturing cost and efficiency of the dental handpiece depend to a large extent on the movement assembly, and the bearing plays a key role in the movement assembly, the dental handpiece of the present invention, due to the above-mentioned airflow suspension Movement components, so its overall performance is better, the power loss is small, the speed is high, and the noise is low, the heat is low, it is not easy to wear, the life is longer, and the manufacturing cost is lower, and the manufacturing efficiency is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com