Granulator for oil exploitation proppant production

A technology for oil exploitation and proppant, which is applied in the field of granulator for proppant production, can solve the problems of inability to prepare granular proppants of different particle sizes according to requirements, inability to prevent proppant particle size, and excessive size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

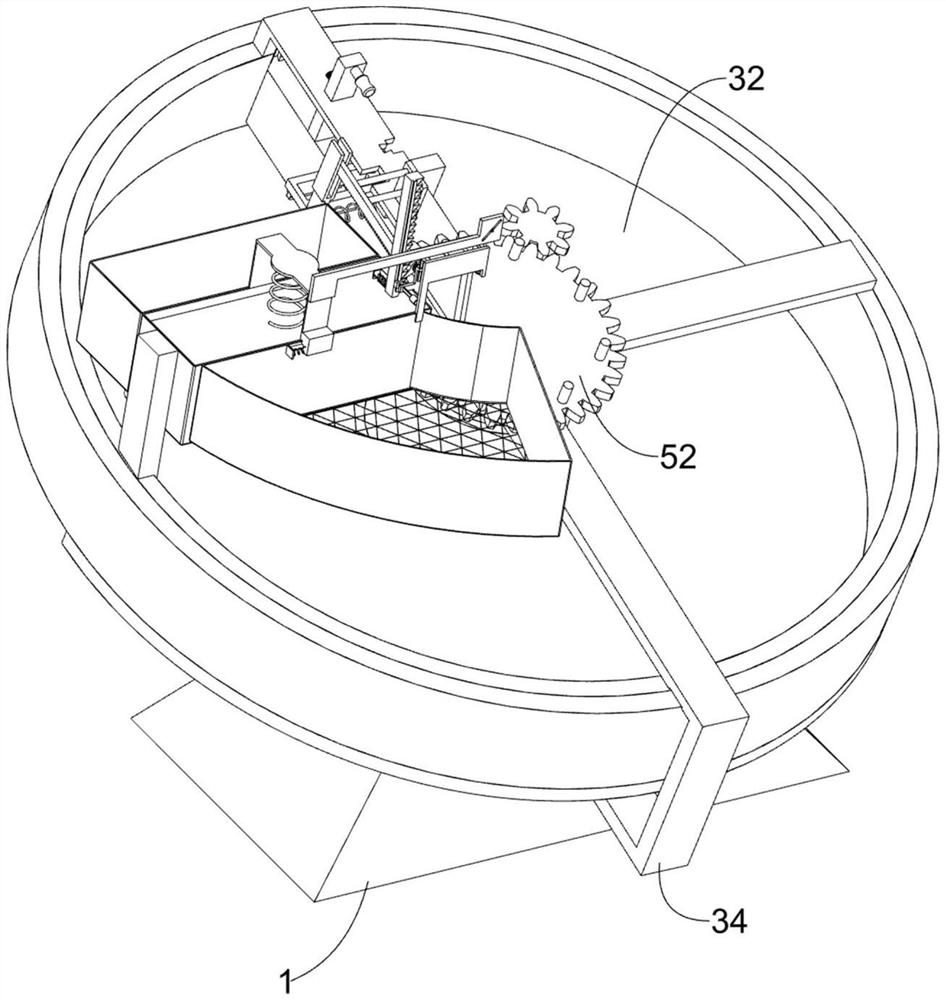

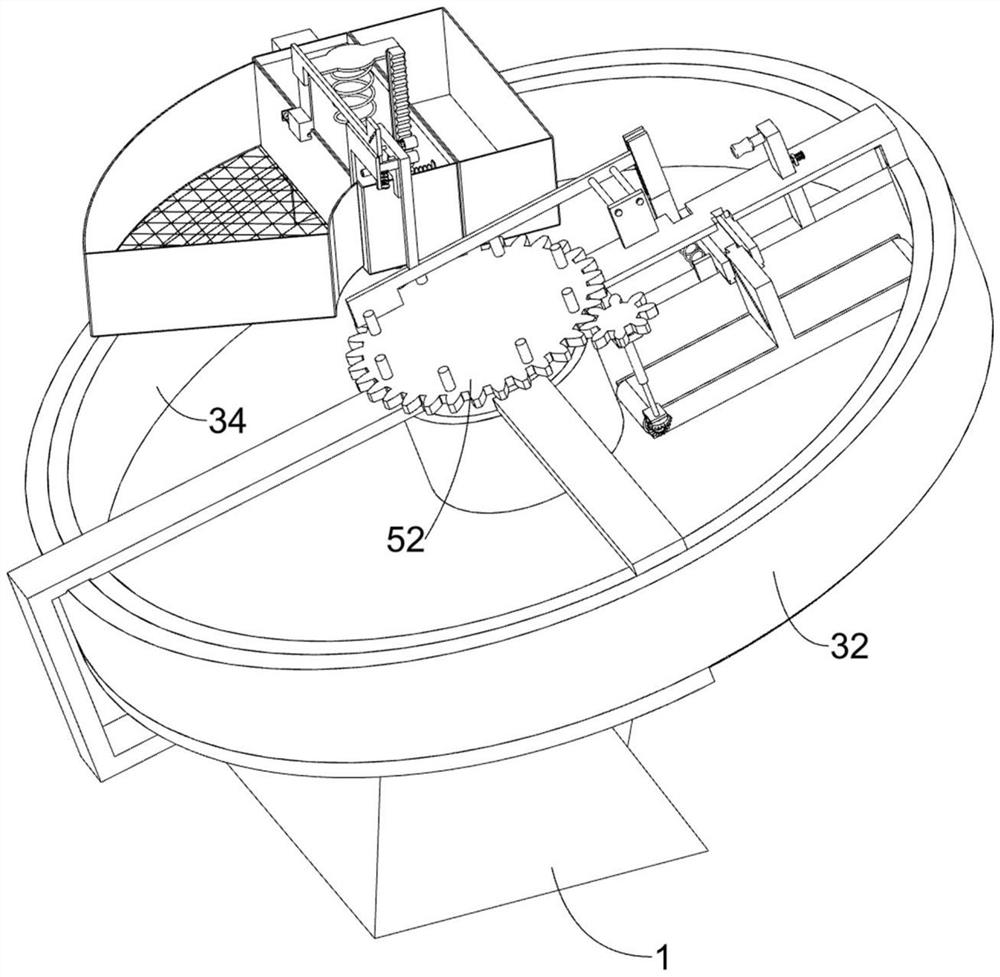

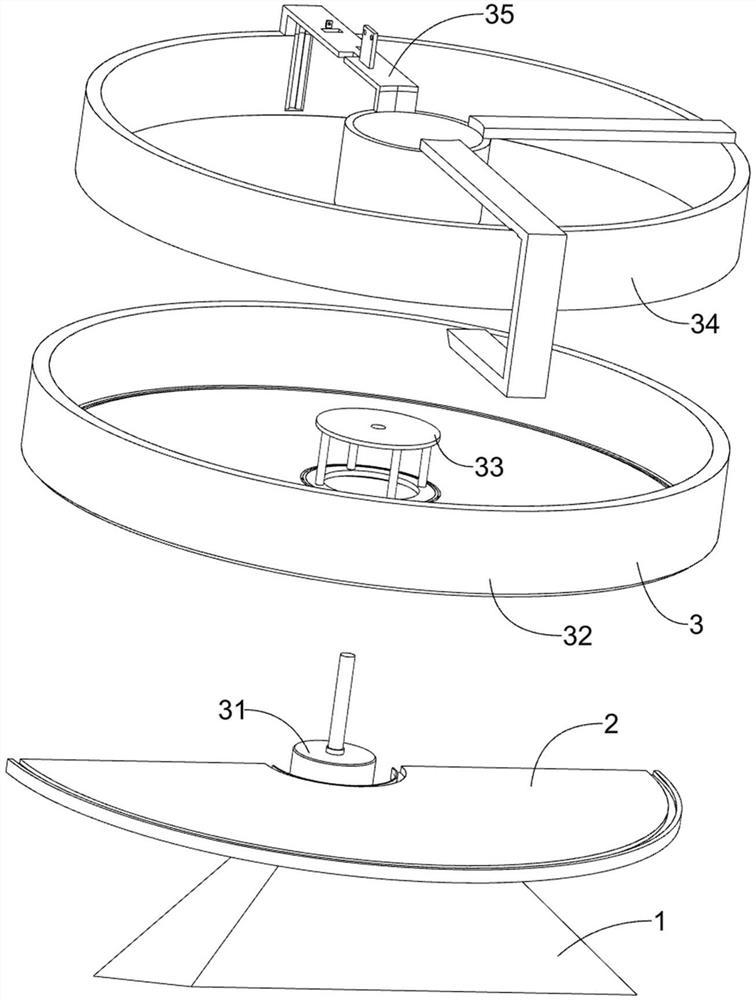

[0033] A granulator for oil production proppant production, such as Figure 1-13 As shown, it includes a support base 1, a support half disk 2, a rotating assembly 3 and a particle size adjustment assembly 4, the support base 1 is connected with a support half disk 2, the rotation assembly 3 is located on the support base 1, and the rotation assembly 3 It is used to make the wet proppant powder into granules. The particle size adjustment assembly 4 is arranged on the rotating assembly 3. The particle size adjustment assembly 4 is used to adjust the particle size of the produced granular proppant.

[0034]The rotating assembly 3 includes a motor 31, a rotating circular frame 32, a transmission frame 33, a circular support frame 34 and a first support frame 35, the motor 31 is installed on the support base 1, and the motor 31 is used to drive the transmission frame 33 and The upper device is reversed, and the supporting half disc 2 is rotatably connected with a rotating circular...

Embodiment 2

[0038] On the basis of Example 1, such as Figure 5-13 As shown, it also includes a ceramsite kneading assembly 5, which is arranged on the rotating assembly 3. The ceramsite kneading assembly 5 is used to make the proppant with too large particle size reach a suitable size. The ceramsite kneading assembly 5 Including a spur gear 52, a first clamping column 53, a support plate 54, a spur frame 55, a second support frame 56, a first push frame 561, a second spring 562, a second push frame 563, a transmission roller 57, and a friction belt 58. Bevel gear 59 and bevel gear frame 510. The output shaft of the motor 31 is connected with a spur gear 52. The spur gear 52 is used to drive the spur gear frame 55 and its upper device to rotate clockwise. The top of the spur gear 52 is distributed and connected with a first card. Column 53, the first support frame 35 is connected with a support plate 54, the support plate 54 is rotatably connected with a spur rack 55, the spur rack 55 mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com