Optical fiber grinding machine

A grinding machine and optical fiber technology, which is applied in grinding machine tools, grinding devices, grinding machine parts, etc., can solve the problem of increased labor intensity of operators, and achieve the effect of improving connection stability, reducing standby time, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

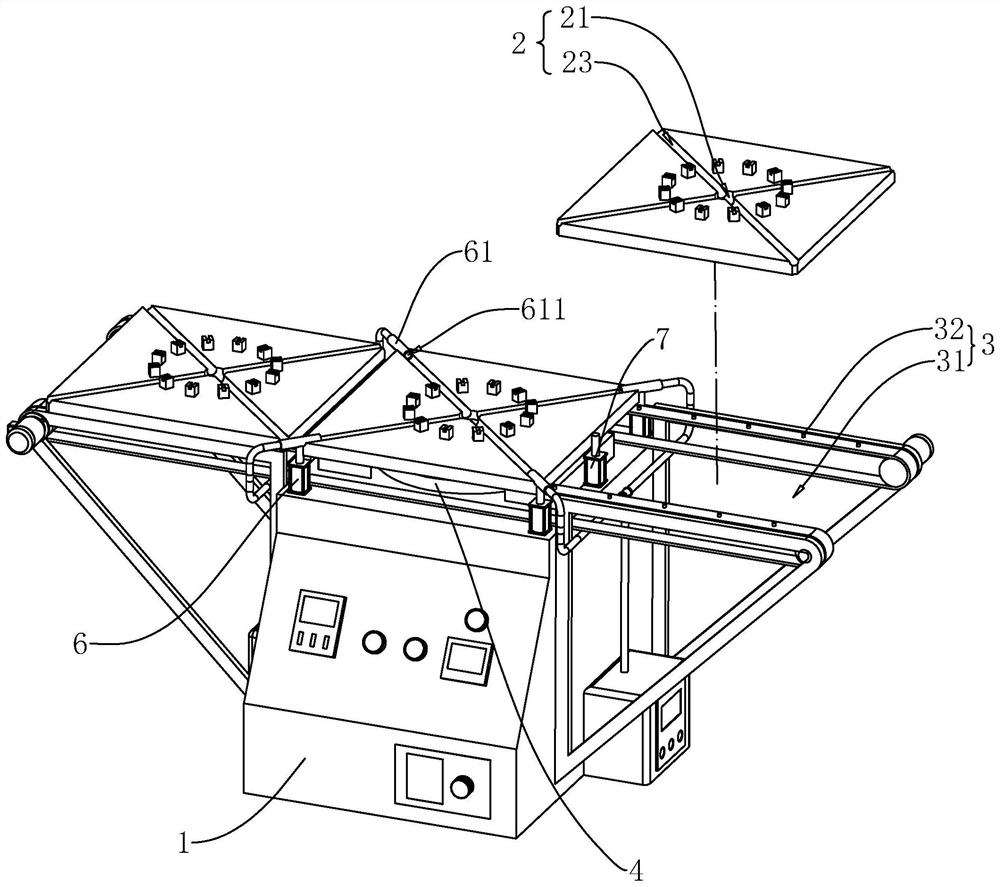

[0041] The following is attached Figure 1-6 The application is described in further detail.

[0042] The embodiment of the present application discloses an optical fiber polishing machine.

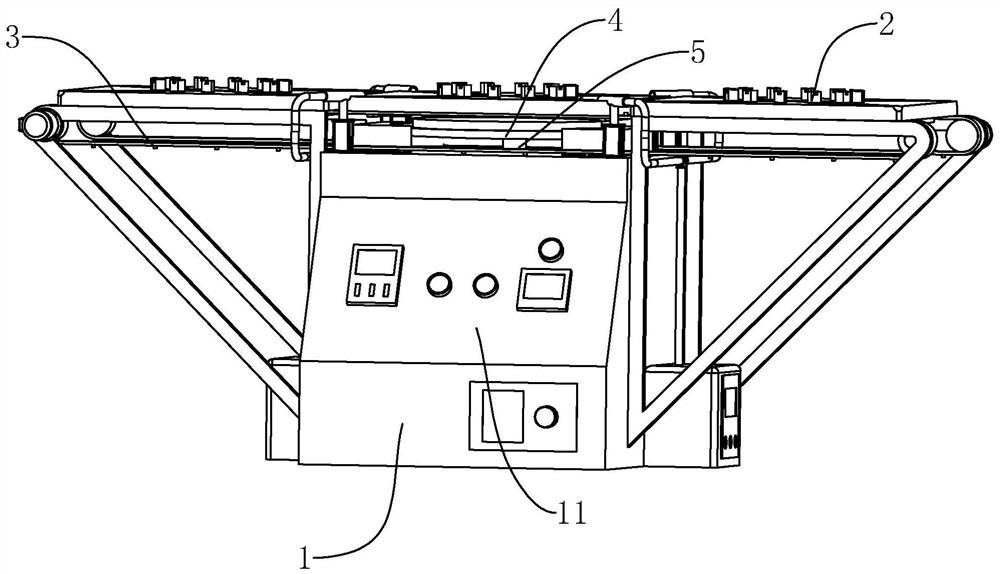

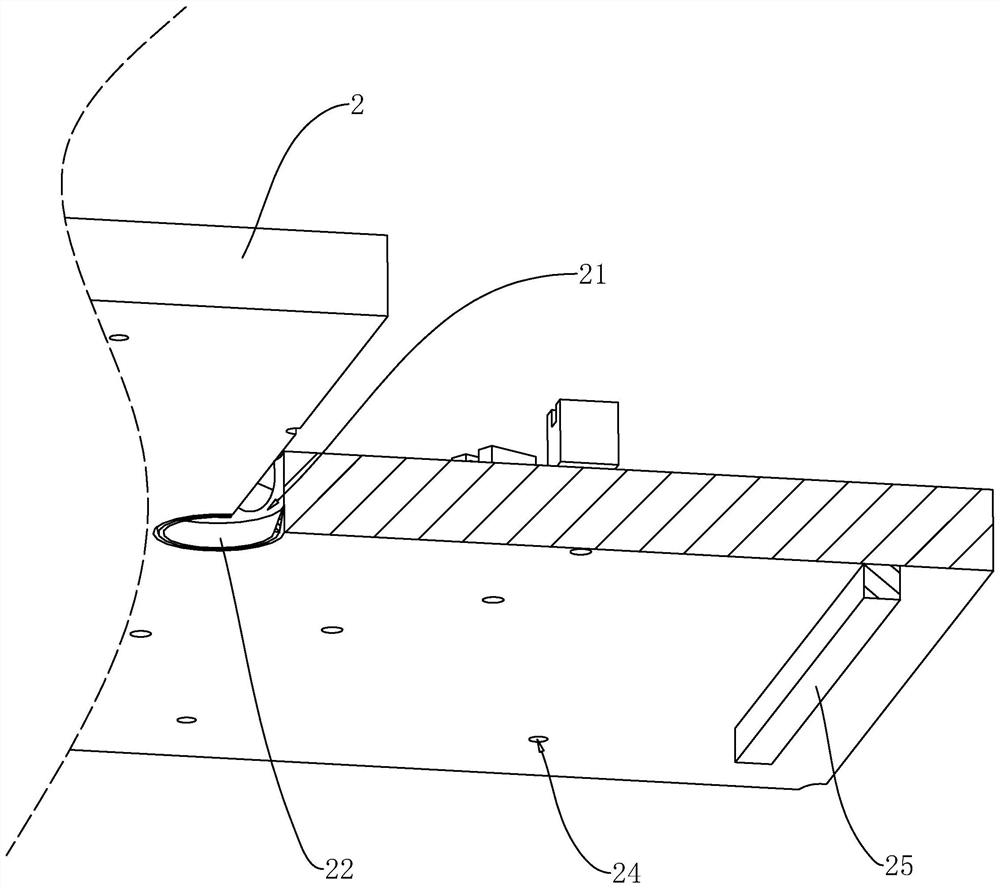

[0043] refer to figure 1 , figure 2 , the optical fiber polishing machine includes a base 1, a plurality of optical fiber chucks 2 inserted with optical fibers, and a delivery track 3 for transporting a plurality of optical fiber chucks 2, the delivery track 3 is rotatably connected to the base 1, and the delivery track The feeding surface of 3 is parallel to the top of support 1. The feeding track 3 has elasticity, and the feeding track 3 is a rubber conveyor belt driven by a motor. A plurality of optical fiber chucks 2 are arranged at intervals on the surface of the delivery track 3 along the length direction of the delivery track 3 . The top end of the base 1 is provided with a grinding disc 4 for contacting the end face of the optical fiber, and the base 1 is provided with a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com