Corrosion-resistant construction process for bracelet type anode

A construction technique and corrosion-resistant technology, which is applied in the field of anti-corrosion construction of underwater pipelines, can solve the problems of anode material consumption, large number of bracelet-type anode installations, and cumbersome disassembly and assembly, so as to increase the reaction contact area, enhance the anti-corrosion protection effect, and facilitate construction. The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

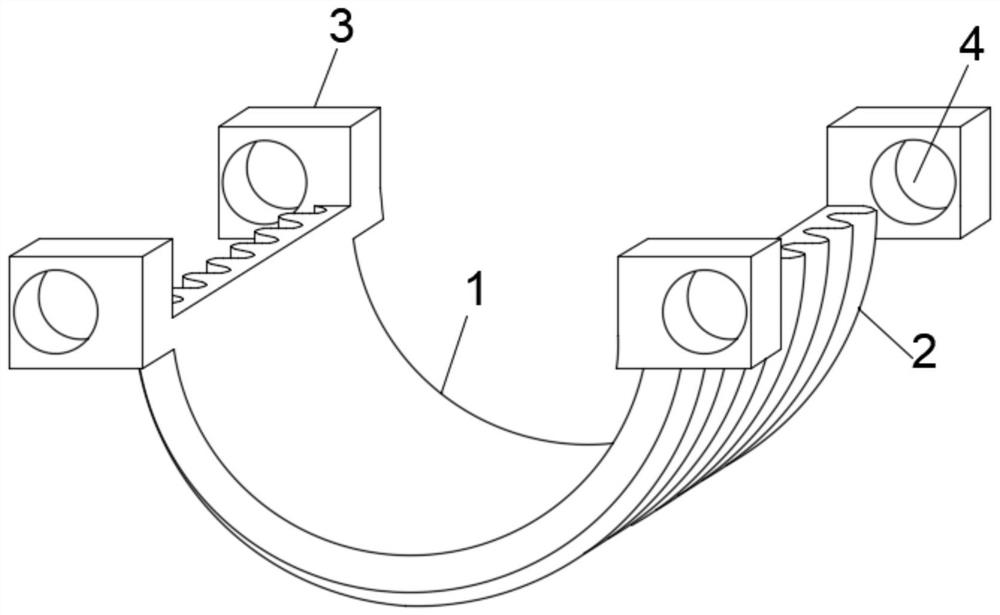

[0034] Example 1: See figure 1 The bracelet anode 1 is a circular arc-shaped surface structure adapted to the circumferential surface of the tubular 5, and the outer arched surface is provided with a pleated surface 2 having a continuous corrugated shape, and the bracelet anode 1 is vertically disposed vertically. The ear plate 3, each of the ear plate 3 opens a positioning hole 4, respectively.

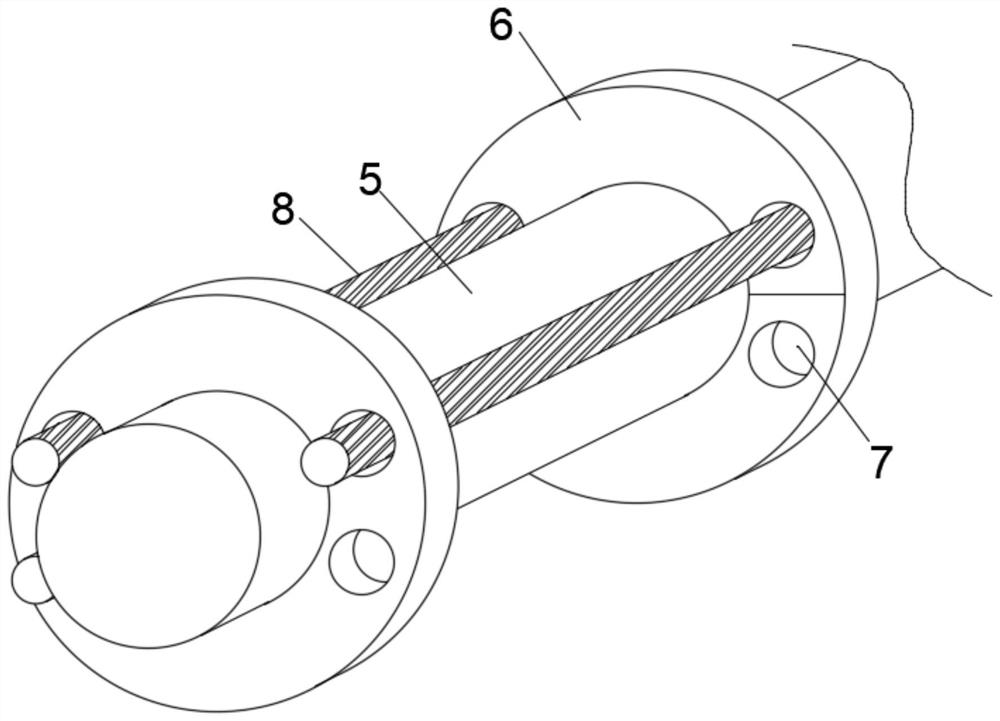

[0035] In the present embodiment, the flange 6 is a circular structure made of two semi-circular cyclics, and one guide hole 7 is opened at both ends of each semicircular ring.

[0036] The abutment surface of the bracelet anode 1 is provided with a pleated surface 2 having a continuous corrugated shape, and it is possible to increase the reaction contact area, enhance the anti-corrosion protection effect, and vertically vertically on both ends of the bracelet anode 1, and can be used with tubes The screw 8 on both sides of the body 5 mates, which is convenient for batch disassembly to t...

Embodiment 2

[0037] Example 2: The specific production process of the bracelet anode 1 is as follows:

[0038] Step 1: Secure the same length of the wire in the inside of the core, and the outer side of the core is fixed to the same positioning rod;

[0039] Step 2: Place the outer mold, heat the core to 300 ° C ± 50 ° C, and place the iron core in the outer mold, so that the iron rods are in contact with the outer mold, ensuring that the core is in the same center with the outer mold, and then arranges the mold. After the mold, after the mold, each positioning rod is in contact with the inner mold;

[0040] Step 3: An anodic melt of 680 ° C to 750 ° C is cast in the mold, the outer mold.

[0041] Step 4: Cool molding, obtain the bracelet anode 1 having a circular arc-shaped curved surface structure having a continuous corrugated shape 2;

[0042] Step 5: Welding the ear plate 3 after the molded bracelets 3, resulting in the final finished product.

[0043] A hardcore is fixed in the inside of...

Embodiment 3

[0044] Example 3: See 1-2: The corrosion resistant construction process of the bracelet anode 1 on the tubular 5 includes the following specific steps:

[0045] S1: The flange ring 6 is customized according to the outer diameter size of the tube 5, so that the flange 6 can be attached to the tubular body 5, and two guiding holes 7 are respectively opened on both sides of the flange ring;

[0046] S2: First determine the mounting section of the bracelet anode 1 on the pipe body 5, and then weld the multi-group flange 6 in the corresponding mounting segment, and perform anti-corrosion treatment on the weld;

[0047] S3: Each set of flanges 6 is set to two, controlling the distance between the two flanges 6 per group, so that it can be placed in 3-5 pair of bracelet anode 1 distributed up and down;

[0048] S4: The tubular 5 of each pair of engagement between the bracelet anode 1 is connected between the two flanges 6, and then inserted between the two guide holes 7 corresponding to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com