Method for automatically controlling water temperature of circulating water in winter

An automatic control system and circulating water technology, applied in lighting and heating equipment, heat exchange equipment, etc., can solve the problems of lack of control equipment, unstable circulating water outlet temperature, and insufficient cooling of circulating water temperature, so as to achieve constant temperature and prevent The effect of upstream wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

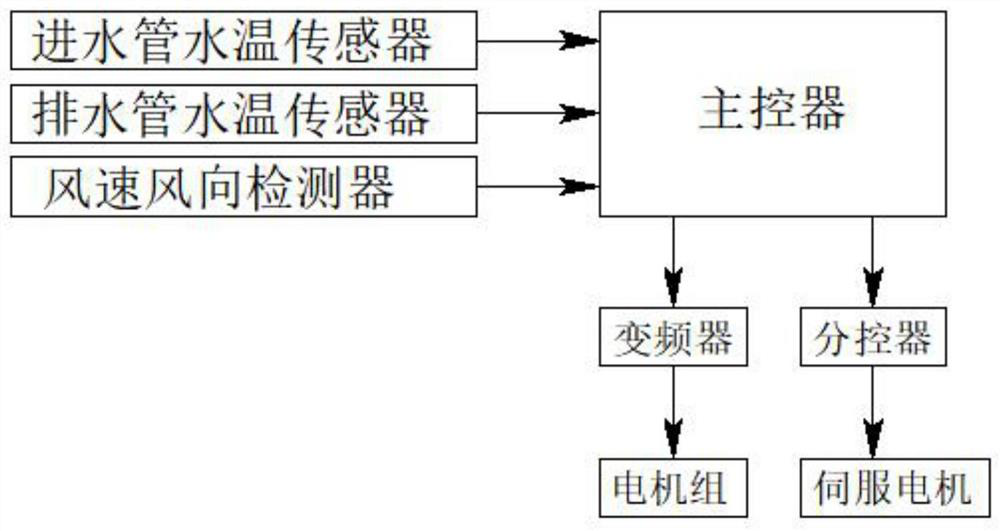

[0027] An automatic water temperature control method for circulating water in winter. The automatic water temperature control system includes a motor unit control system and an air intake volume control system. Both the motor unit control system and the air intake volume control system are installed in the main controller. The sensor, the water temperature sensor of the drain pipe, the main controller, the frequency converter and the motor unit are composed, and the air intake volume control system is composed of the wind speed and direction detector, the main controller, the sub-controller and the servo motor.

[0028] The control system of the motor unit can measure the water temperature in the circulating water inlet and the circulating water outlet respectively, and upload the temperature data to the main controller. The water temperature is compared with the set temperature range, and feedback is made according to the calculation and comparison results, and the signal is t...

Embodiment 2

[0031] The water temperature sensor of the water inlet pipe and the water temperature sensor of the drain pipe are respectively installed at the position of the circulating water inlet and the position of the circulating water outlet;

[0032] The water temperature sensor of the water inlet pipe and the water temperature sensor of the drain pipe are used to respectively detect the water temperature of the circulating water inlet and the circulating water outlet, and upload the detected values to the main controller.

[0033] The main controller receives the data uploaded by the water temperature sensor of the water inlet pipe and the water temperature sensor of the drain pipe. The main controller compares the water temperature of the circulating water inlet and the water temperature of the circulating water outlet, calculates the cooling efficiency and compares the water temperature setting value of the circulating water outlet;

[0034] The main controller transmits signals ...

Embodiment 3

[0039] The wind speed and direction detector is installed at the air inlet of the fan unit, used to detect the wind speed and wind direction of the external environment of the air inlet, and feed back the signal to the main controller;

[0040] The servo motor is installed inside the air inlet, and the motor shaft of the servo motor is rotationally connected with the blades at the opening of the air inlet for the servo motor to drive the rotation of the blades.

[0041]The wind speed and direction detector can detect the wind speed and wind direction of the external environment at the air inlet, and control the rotation of the blades on the inner wall of the air inlet through the servo motor, which can flexibly change the distance between the blades, change the air intake volume of the air inlet, and prevent airflow Backflow wind is generated inside the tuyere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com