Tab-free lithium ion battery and manufacturing method thereof

An ion battery, electrodeless ear lithium technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc. Improve battery safety performance, avoid short-circuit risks, and fix firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

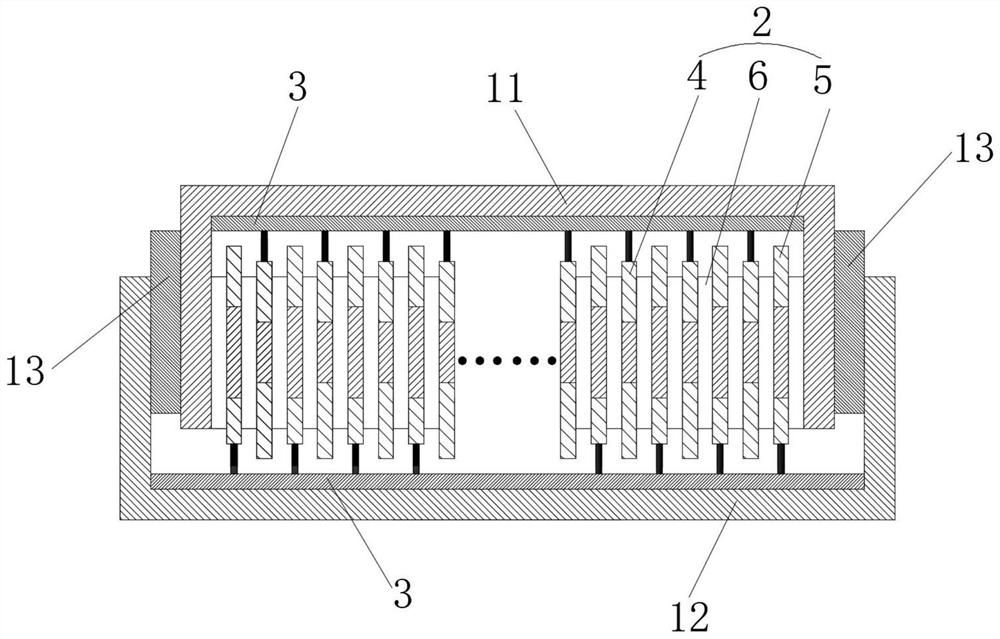

[0034] Please refer to Figure 1 to Figure 3 , Embodiment 1 of the present invention provides a tabless lithium-ion battery.

[0035] The electrodeless lithium-ion battery includes a positive electrode conductive case 11 and a negative electrode conductive case 12, the positive electrode conductive case 11 is fastened inside the negative electrode conductive case 12, and the two are fastened together to form a sealed cavity inside , the inside of the cavity is equipped with a battery cell 2 and an electrolyte, and an insulating sealing ring 13 is provided between the positive electrode conductive shell 11 and the negative electrode conductive shell 12. Further, in this embodiment, the negative electrode The size of the conductive shell 12 is larger than the size of the positive conductive shell 11, and the positive conductive shell 11 is installed inside the negative conductive shell 12. In other embodiments, the size of the positive conductive shell 11 can also be larger than...

Embodiment 2

[0044] Please refer to Figure 1 to Figure 3 Embodiment 2 of the present invention provides a method for manufacturing the tabless lithium-ion battery described in Embodiment 1: comprising the following steps:

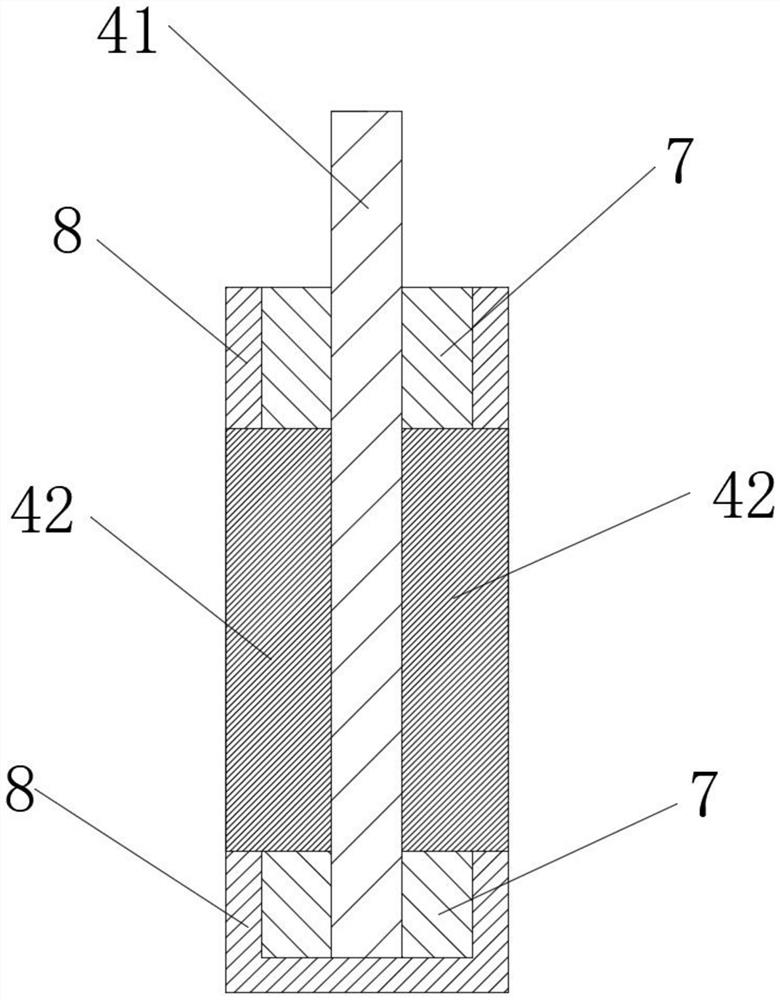

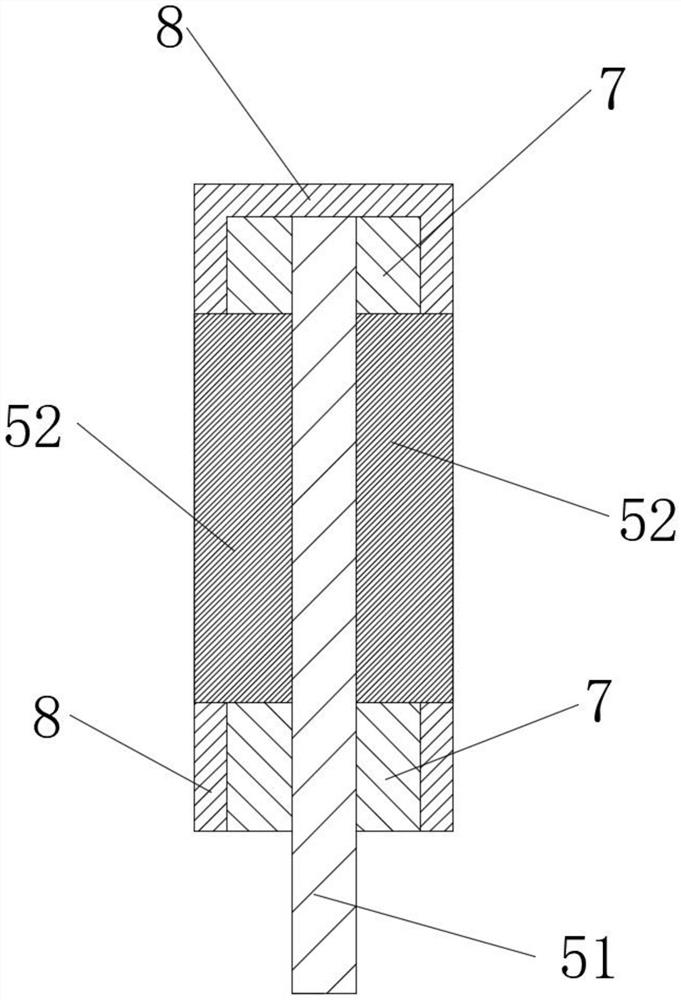

[0045] Step S1: Prepare the positive electrode active material member and the negative electrode active material member; coat the positive electrode active material member on one or both sides of the positive electrode current collector 41 to form the positive electrode coating layer 42; coat the negative electrode active material material member The negative electrode coating layer 52 is formed on one side or both sides of the negative electrode current collector 51 .

[0046] Step S2: The surface of the positive electrode current collector 41 is not completely coated with positive electrode active material components, and there is still a part of the empty foil area; at the same time, the surface of the negative electrode current collector 51 is not completely coated...

Embodiment 3

[0052] Embodiment 3 of the present invention provides a detailed description of Embodiment 2.

[0053] Firstly, positive electrode active material slurry and negative electrode active material slurry are prepared.

[0054] The positive electrode active material slurry is coated on the positive electrode current collector 41 to form the positive electrode coating layer 42 ; the negative electrode active material slurry is coated on the negative electrode current collector 51 to form the negative electrode coating layer 52 .

[0055] The main component of the positive electrode active material slurry is lithium cobaltate, the surface density is 12.10mg / cm2, and the compacted density is 4.15g / cm3.

[0056] The main component of the negative electrode active material slurry is artificial graphite, the surface density is 7.11mg / cm2, and the compacted density is 1.50g / cm3.

[0057] An insulating coating 7 made of ceramic material is coated on both sides of the positive electrode co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com