Novel combined frequency conversion and speed reduction all-in-one machine

A combined, all-in-one technology, applied in electromechanical devices, electric components, control of mechanical energy, etc., can solve the problems of limited use, transportation, maintenance difficulties, and single structure, and achieve low manufacturing and maintenance costs, convenient transportation and layout. , The effect of flexible installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

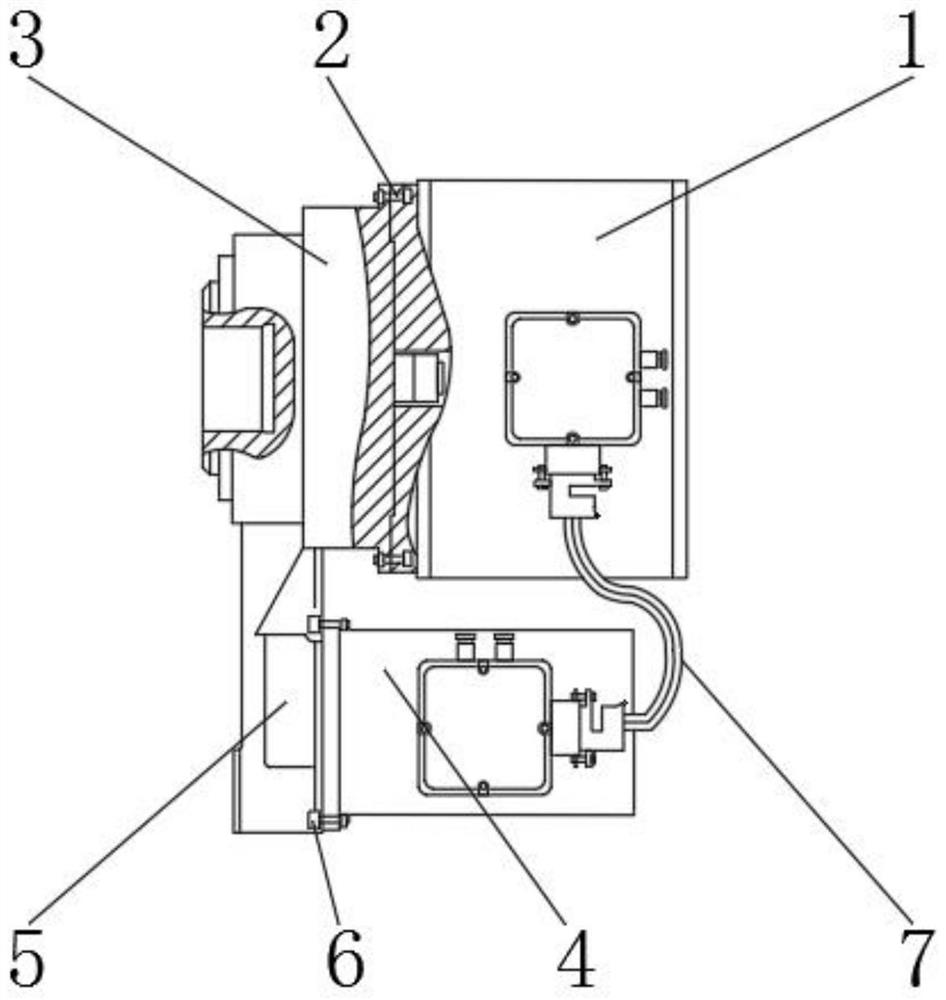

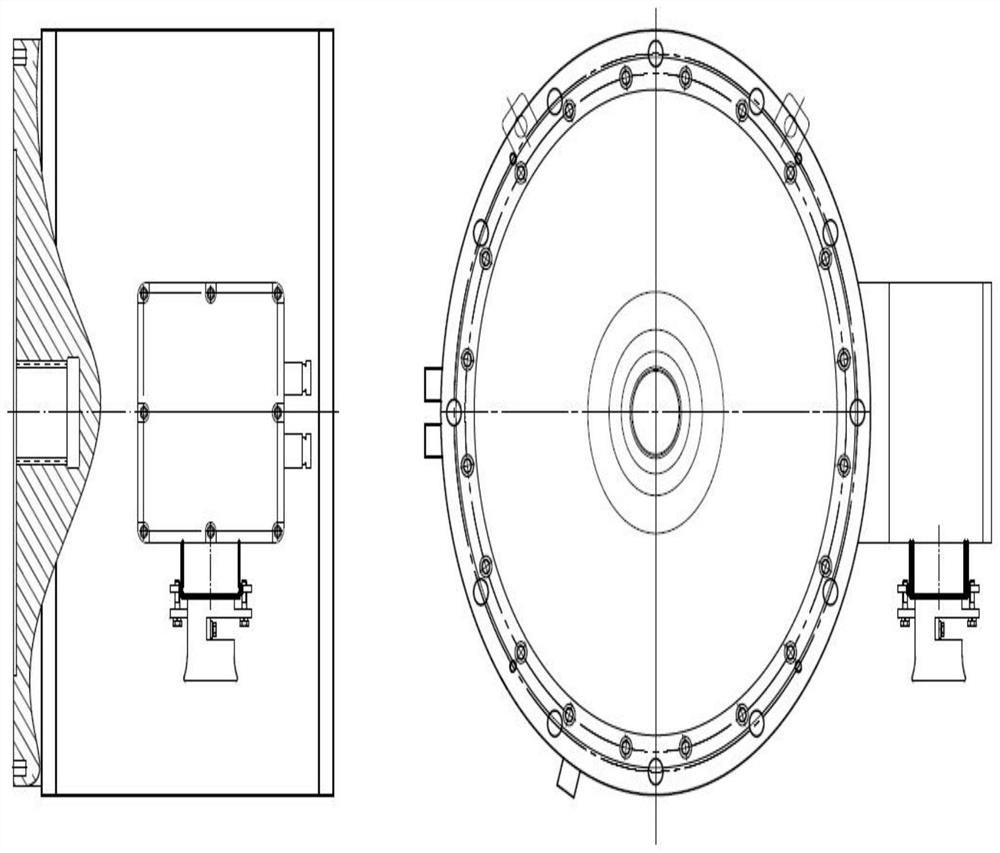

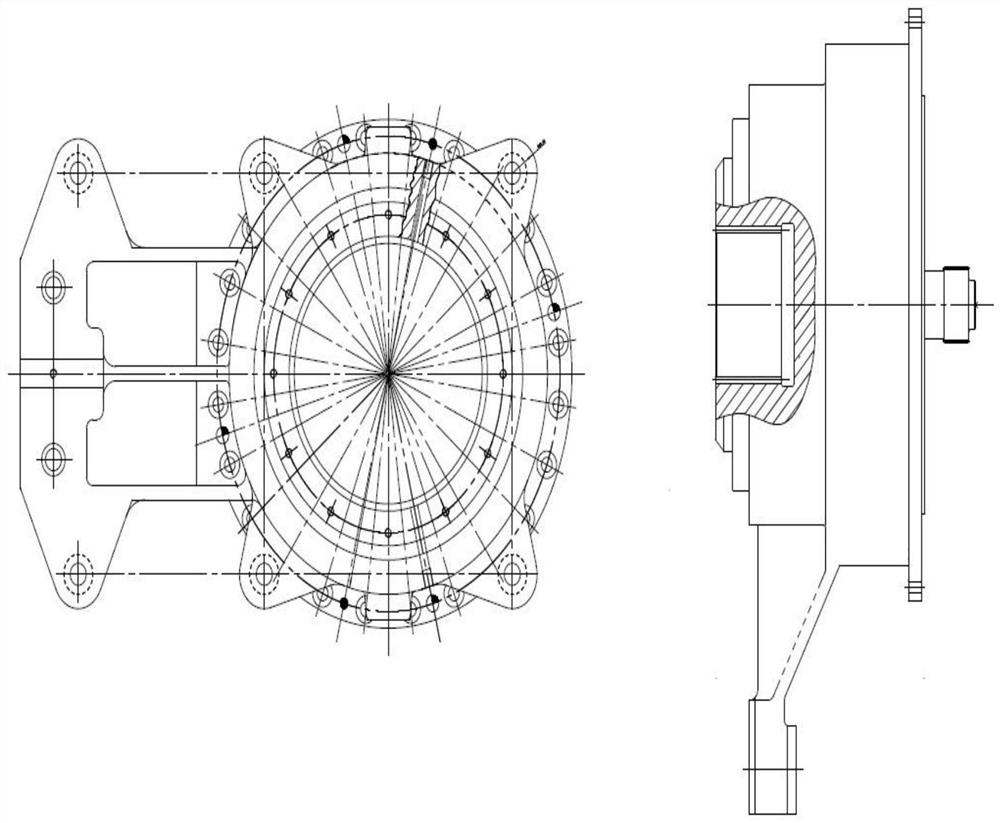

[0017] Such as Figure 1-3 As shown in the figure, a new combined frequency conversion deceleration integrated machine includes a motor 1, a reducer 3 is arranged on the outer surface of one end of the motor 1, a first bolt 2 is arranged between the motor 1 and the reducer 3, and the other end of the reducer 3 The outer surface is provided with a connection plate 5 , and the outer surface of one end of the connection plate 5 is provided with a frequency converter 4 , a second bolt 6 is provided between the connection plate 5 and the frequency converter 4 , and a cable 7 is provided between the motor 1 and the frequency converter 4 .

[0018] Further, the outer surface of one end of the motor 1 is detachably connected to the outer surface of one end of the reducer 3 through the first bolt 2 .

[0019] Further, there is sometimes a fixing groove between the reducer 3 and the connecting plate 5 , and the outer surface of the other end of the reducer 3 is detachably connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com