Process for purification of hydrochloric acid pickling solution and treatment of sludge

A technology of sludge treatment and pickling solution, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of equipment investment for a large amount of sludge and concentrated brine, and achieve The effect of convenient handling and transportation, reducing pollution and reducing the area of the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the present invention will be clearly and completely described below in conjunction with the embodiments. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Although representative embodiments of the present invention have been described in detail, those skilled in the art to which this invention pertains will appreciate that various modifications and changes can be made therein without departing from the scope of the invention. Accordingly, the scope of the present invention should not be limited to the embodiments, but should be defined by the appended claims and their equivalents.

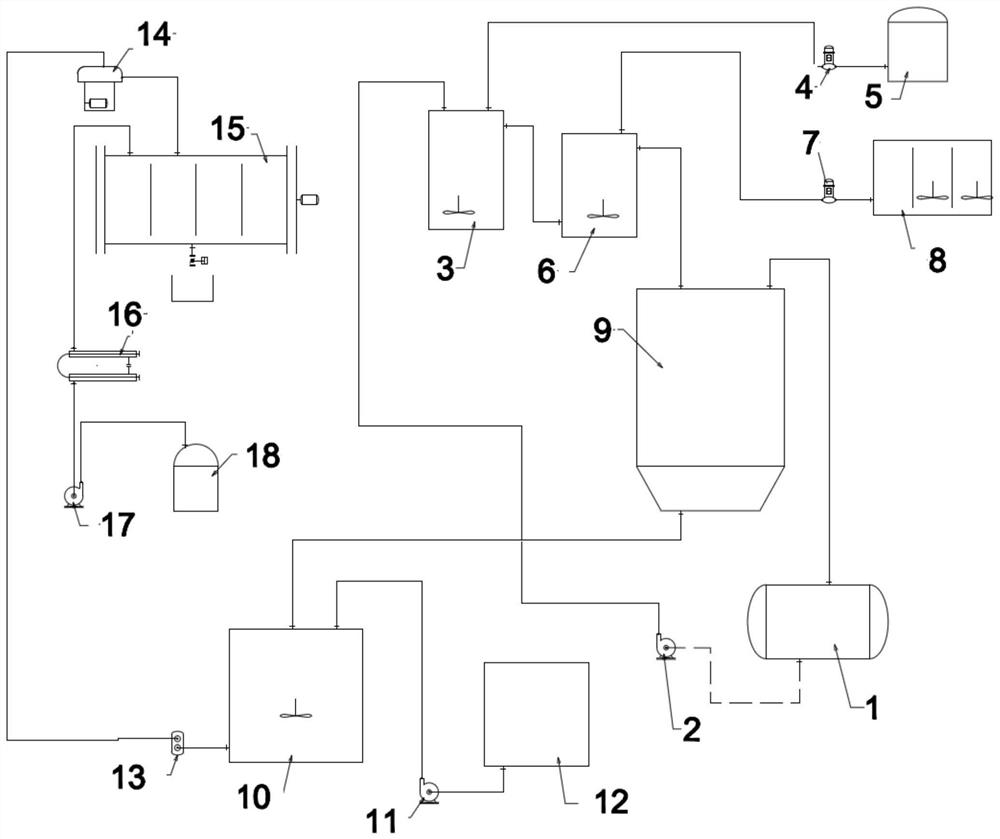

[0026] Such as figure 1 Shown, hydrochloric acid pickling liquid purification and sludge treatment process of the present invention may further comprise the steps:

[0027] S1. The pickling solution to be purified in the acid circulation tank is transported to the first mixing reaction tank with coag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com