Asphalt mixture doped with flocculent basalt fibers

A technology of basalt fiber and asphalt mixture, which is applied in the field of road engineering materials, can solve the problems of not improving the pavement strength, poor water stability of the mixture, affecting durability, etc. The effect of water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

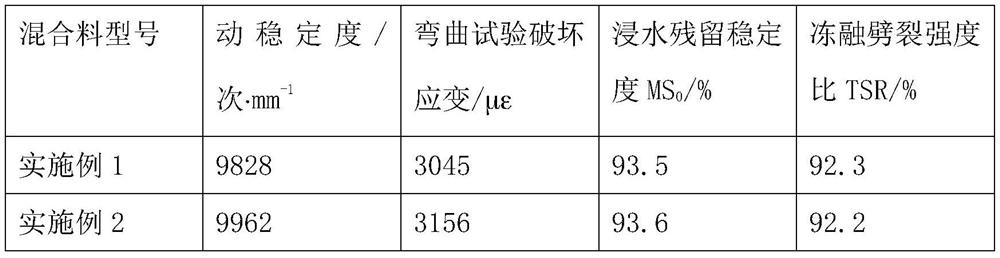

Embodiment 1

[0037] First heat the SBS modified asphalt to a molten state in an oven at 160°C, and keep it warm for later use. Coarse aggregate, fine aggregate and mineral powder in advance (the ratio of 1# coarse aggregate: 2# coarse aggregate: fine aggregate: mineral powder to the total mass of mineral aggregate is 40.0:33.0:16.5:10.5), The flocculent basalt fiber with 3‰ of the total mass of the asphalt mixture was heated at 185°C for more than 5 hours. Mix the coarse aggregate, fine aggregate, mineral powder and flocculent basalt fiber in the mixing pot for 25 seconds, then add the SBS modified asphalt (accounting for 4.5% of the total mass percentage of the asphalt mixture) for step 1 heat preservation, and continue mixing 90 to 95 seconds to prepare the asphalt mixture mixed with flocculent basalt fibers.

Embodiment 2

[0039] First, heat the SBS modified asphalt in an oven at 165°C to a molten state, and keep it warm for later use. Coarse aggregate, fine aggregate and slag powder (the ratio of 1# coarse aggregate: 2# coarse aggregate: fine aggregate: slag powder to the total mass of mineral material is 42.0:30.0:18.0:10.0) and The flocculent basalt fibers of 4‰ of the total mass of the asphalt mixture were heated at 180°C for more than 5 hours. Mix the coarse aggregate, fine aggregate, mineral powder and flocculent basalt fiber in the mixing pot for 25 seconds, then add the SBS modified asphalt (accounting for 5.0% of the total mass percentage of the asphalt mixture) for heat preservation in step 1, and continue mixing 90 to 95 seconds to prepare the asphalt mixture mixed with flocculent basalt fibers.

Embodiment 3

[0041] First, heat the SBS modified asphalt to a molten state in an oven at 170°C, and keep it warm for later use. Coarse and fine aggregates and slag powder (the ratio of 1# material: 2# material: fine aggregate: slag powder to the total mass is 45.0:30.0:16:9.0) and 4.5‰ of the total mass of flocculent basalt fiber Heat at 190°C for more than 5h. Mix the coarse and fine aggregates, mineral powder and flocculent basalt fiber in the mixing pot for 25 seconds, then add the SBS modified asphalt (accounting for 5.6% of the total mass percentage) for heat preservation in step 1, and continue mixing for 90-95 seconds to prepare the prepared The above-mentioned asphalt mixture mixed with flocculent basalt fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com