Compound feed additive and feed for laying hens in growing period

A compound feed and laying hen feed technology is applied in the field of compound feed additives and laying hen feed in the breeding period. The effect of absorption utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

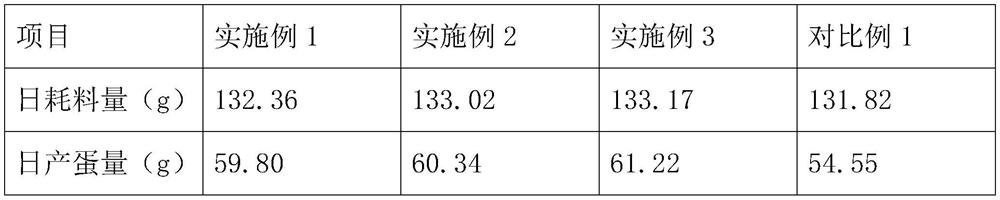

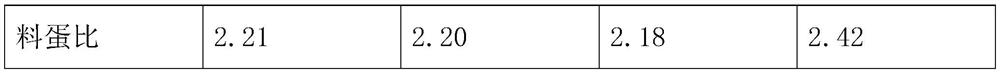

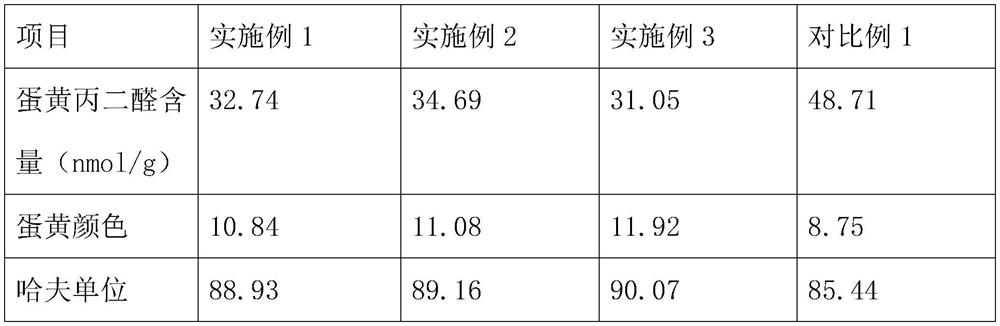

Examples

Embodiment 1

[0025] A preparation method of a compound feed additive, comprising the following steps:

[0026] S1. Mix shrimp shell powder, bran, and glucose in a mass ratio of 100:20:0.5, adjust the water content to 50%, and sterilize at 115°C for 15 minutes to obtain a mixture;

[0027] S2. Inoculating Phellinus mycelium into the mixture, solid-state fermentation at 26°C for 16 days to obtain a fermented material, wherein the mass ratio of Phellinus mycelia to the mixture is 0.4:100;

[0028] S3. Dry the fermented material at 55° C. until the water content is 5%, and crush it to 60 mesh.

[0029] The preparation method of Phellinus mycelium is:

[0030] Set the size to 1cm 2 The activated Phellinus moss was cut into 4 pieces, inoculated in 100mL sterilized liquid seed medium, cultivated for 14 days at a temperature of 28°C and a shaker speed of 125r / min, and filtered to obtain Phellinus Silk, wherein, in terms of mass percentage, the components of the liquid seed medium are: 2% sucros...

Embodiment 2

[0035] A preparation method of a compound feed additive, comprising the following steps:

[0036] S1. Mix shrimp shell powder, bran, and glucose in a mass ratio of 100:30:1, adjust the water content to 60%, and sterilize at 115°C for 30 minutes to obtain a mixture;

[0037] S2. Inoculating Phellinus mycelium into the mixture, solid-state fermentation at 30°C for 12 days to obtain a fermented material, wherein the mass ratio of Phellinus mycelia to the mixture is 1:100;

[0038] S3. Dry the fermented material at 65°C until the water content is 3%, and crush it to 100 mesh.

[0039] The preparation method of Phellinus mycelium is:

[0040] Set the size to 1cm 2 The activated Phellinus moss was cut into 4 pieces, inoculated in 100mL sterilized liquid seed medium, cultivated for 14 days at a temperature of 28°C and a shaker speed of 125r / min, and filtered to obtain Phellinus Silk, wherein, in terms of mass percentage, the components of the liquid seed medium are: 2% sucrose, 0....

Embodiment 3

[0045] A preparation method of a compound feed additive, comprising the following steps:

[0046] S1. Mix shrimp shell powder, bran, and glucose in a mass ratio of 100:25:0.6, adjust the water content to 55%, and sterilize at 115°C for 20 minutes to obtain a mixture;

[0047] S2. Inoculating Phellinus mycelium into the mixture, and solid-state fermentation at 28° C. for 14 days to obtain a fermented material, wherein the mass ratio of Phellinus mycelia to the mixture is 0.8:100;

[0048] S3, drying the fermented material at 60° C. until the water content is 4%, and crushing to 80 meshes.

[0049] The preparation method of Phellinus mycelium is:

[0050] Set the size to 1cm 2The activated Phellinus moss was cut into 4 pieces, inoculated in 100mL sterilized liquid seed medium, cultivated for 14 days at a temperature of 28°C and a shaker speed of 125r / min, and filtered to obtain Phellinus Silk, wherein, in terms of mass percentage, the components of the liquid seed medium are:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com