Instant collagen microneedle and preparation method thereof

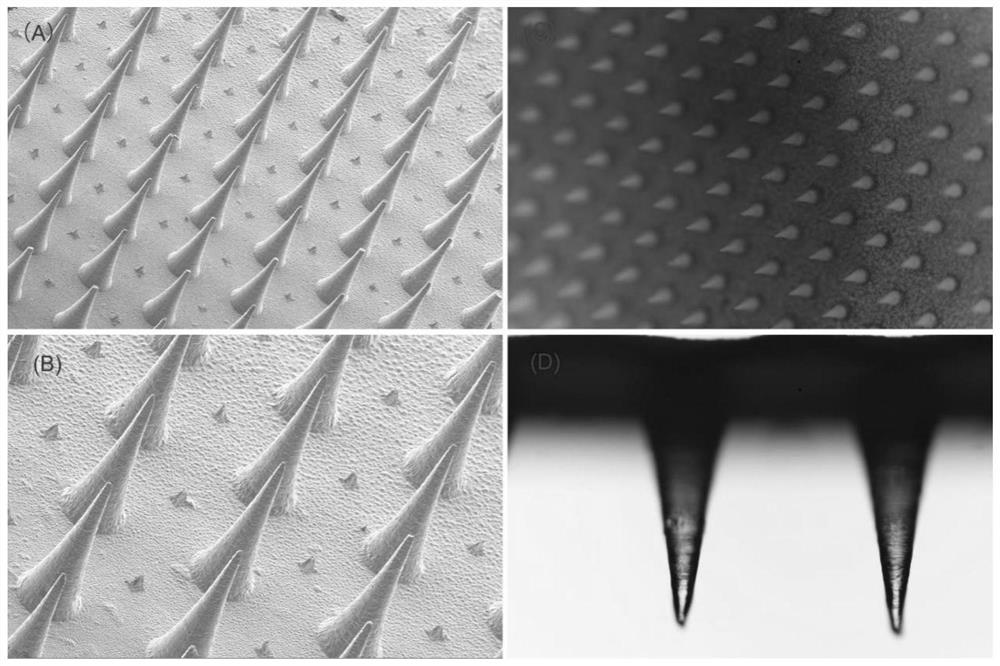

A technology of collagen and recombinant collagen, which is applied in the field of skin care products, can solve the problems of poor solubility of animal collagen, poor formability of recombinant collagen, and difficulty in preparing soluble collagen microneedles, so as to achieve excellent mechanical properties of the needle body and excellent shape The effect of good sex and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Weigh hyaluronic acid, add quantitative water, and prepare hyaluronic acid solutions with concentrations of 1, 5, 10, 15, 20, 25, and 30 mg / ml; stir the solution until there are no powder agglomerates visible to the naked eye, and then put Put it into a vacuum drying oven and heat it to 80°C, and keep the temperature constant for 30 minutes; take it out and stir it evenly again, put it in a vacuum drying oven, keep a vacuum degree of -50kPa at 55°C, and take it out after drying and degassing for 12 hours; after cooling, add recombinant collagen to Its final concentration is: 0.5mg / ml, after stirring evenly, put it into a vacuum drying oven again, at a vacuum degree of -50kPa, dry and defoam at a constant temperature of 25°C for 12h to obtain a microneedle raw material solution.

[0053] Take a certain amount of microneedle raw material solution and add it to the PDMS mold, put it in a vacuum drying oven, dry at a constant temperature of -50kPa vacuum at 25°C for degassin...

Embodiment 2

[0059] Weigh hyaluronic acid, add quantitative water, and make a hyaluronic acid solution with a concentration of 15 mg / ml; stir the solution until there is no powder agglomeration visible to the naked eye, then put it into a vacuum drying oven and heat it to 65°C, and keep the temperature for 30min Stir evenly after taking it out, put it in a vacuum drying oven, keep the vacuum degree of -50kPa, 55°C, dry and defoam for 12 hours, then take it out; after cooling, add recombinant collagen to make the final concentration of recombinant collagen: 0.01, 0.1, 0.3, 0.5, 0.7, 1.0, 5.0, 10.0, 20.0, 30.0mg / ml, stirred evenly, put it into a vacuum drying oven again, with a vacuum degree of -50KPa, and dried at a constant temperature of 20°C for 12 hours to obtain a microneedle raw material solution.

[0060] Take a certain amount of microneedle raw material solution and add it to the PDMS mold, put it into a vacuum drying oven, and dry at a constant temperature of -50kPa vacuum at 20°C. ...

Embodiment 3

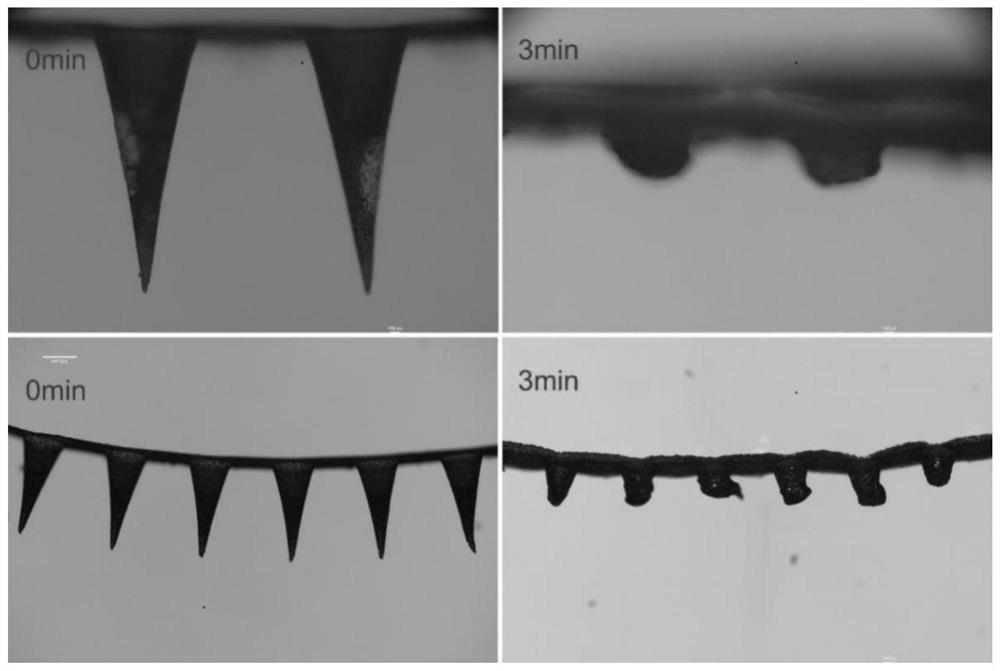

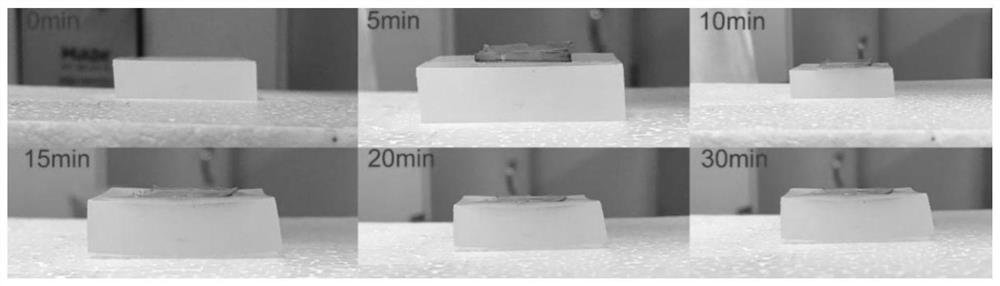

[0066] According to the experimental results of Example 1 and Example 2, in this example, the formation and dissolution of microneedles under the conditions of extreme hyaluronic acid concentration and extreme concentration of recombinant collagen were investigated. Weigh hyaluronic acid, add quantitative water, and make hyaluronic acid solutions with a concentration of 5mg / ml and 30mg / ml; stir the solution until there is no powder agglomeration visible to the naked eye, then put it in a vacuum drying oven and heat it to 65 ℃, constant temperature for 30min; after taking it out, stir again evenly, put it in a vacuum drying oven, keep the vacuum degree of -50kPa, 55℃, take it out after drying and defoaming for 12h; add recombinant collagen to the 30mg / ml hyaluronic acid group after cooling The concentration is 30mg / ml, add recombinant collagen to the 5mg / ml hyaluronic acid group until the concentration is 0.01mg / ml, stir evenly, then put it into the vacuum drying oven again, wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com