An automatic production line for cutting copper rods

An automatic production line, copper rod technology, applied in the direction of shearing device, shearing machine equipment, shearing machine accessories, etc., can solve the problems of unfavorable large-scale production, low degree of automation, and potential safety hazards, and achieve easy overload protection, Reduce labor costs and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings.

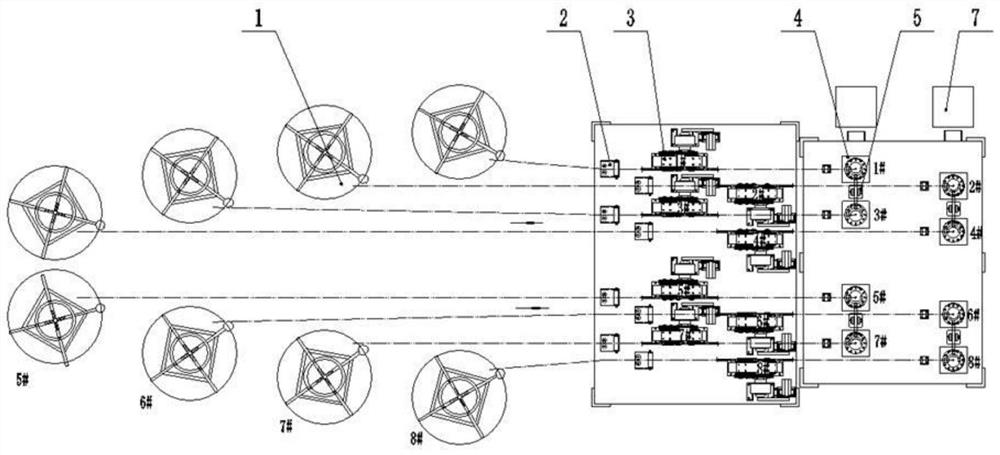

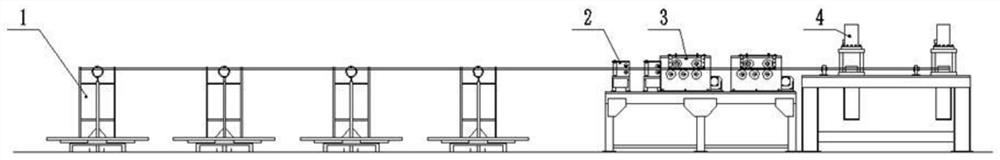

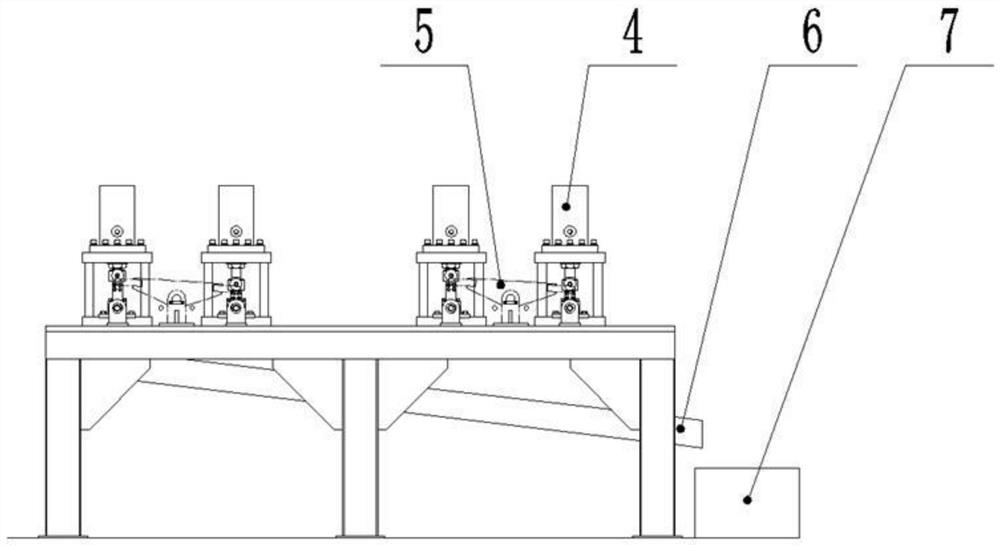

[0053] like Figure 1-3 As shown, an automatic production line for cutting copper rods includes 8 sets of automatic cutting devices for copper rods. Each group of copper bar automatic shearing device includes a feeding pulling part and a shearing part. The feeding and pulling part includes a turntable 1 , a guide roller 2 and a pulling device 3 . The shearing part includes a copper bar shearing machine 4 , a connecting rod mechanism and a discharge chute 6 . A discharge chute 6 is correspondingly arranged below the copper bar shearing machine 4, the discharge chute 6 is inclined, and a finished product collection box 7 is disposed at the inclined outlet. When working, first place the copper rod in a circle on the turntable 1, and manually send the copper rod head into the pulling device 3 to start the equipment. The traction device 3 drives the copper rods to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com