Dust detection and control system for concrete mixing plant based on 5G communication

A technology of detection control system and mixing station, applied in control device, pretreatment control, measurement device, etc., can solve problems such as accelerating the speed of water vapor spreading, and achieve the effect of reducing dust content and improving dust reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

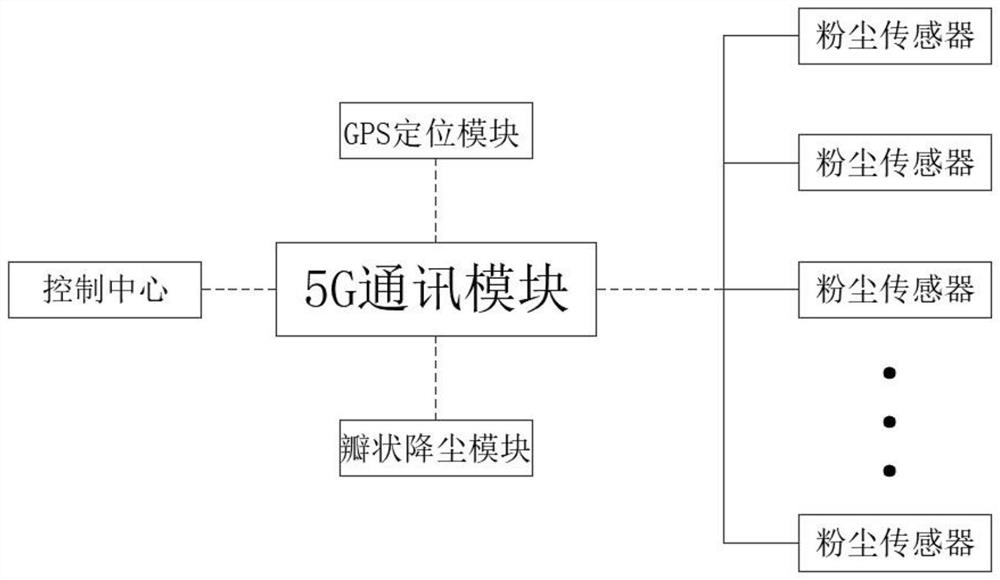

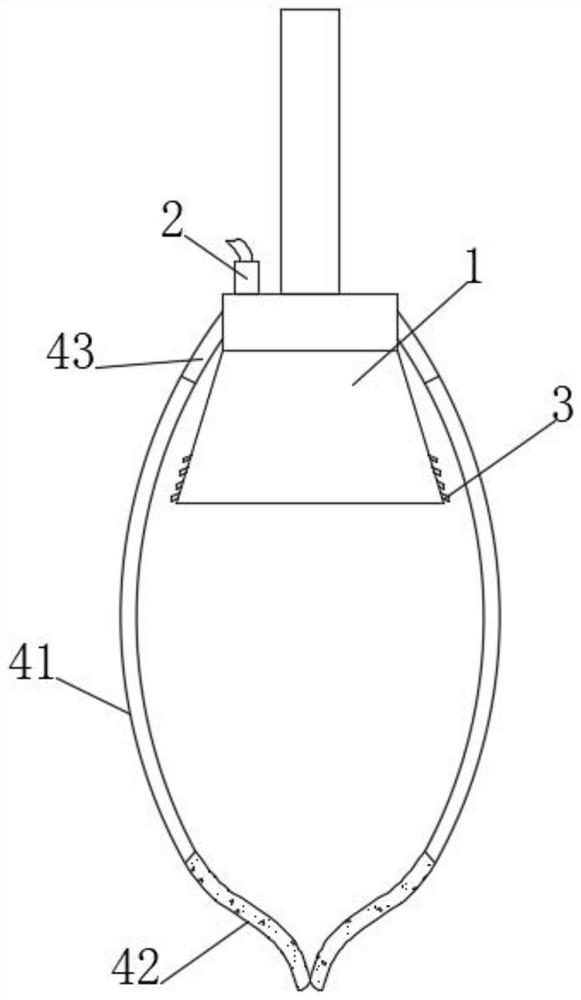

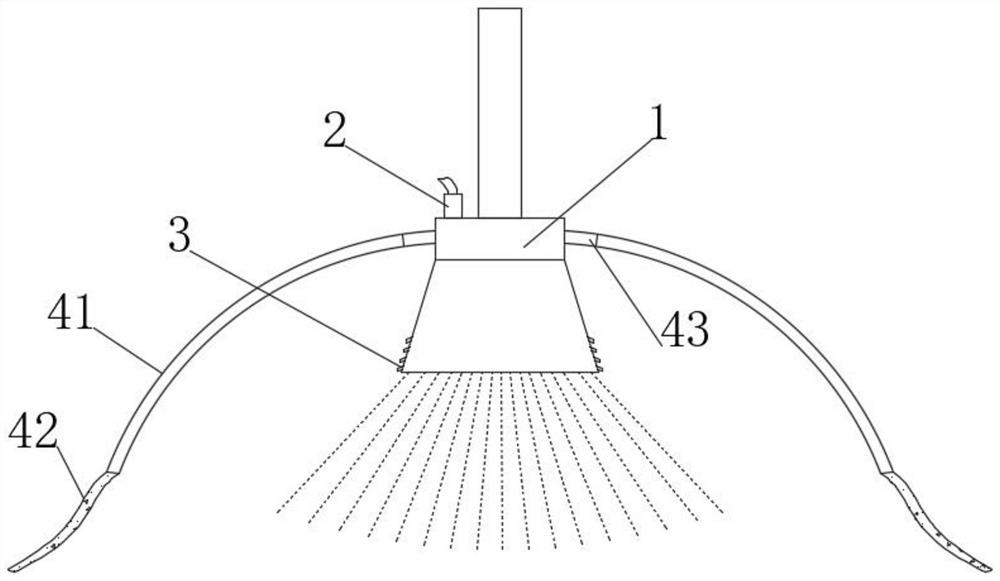

[0041] see figure 1 , a dust detection and control system for concrete mixing plants based on 5G communication, including 5G communication module, dust detection module, GPS positioning module, petal dust suppression module and control center, dust detection module, GPS positioning module, petal dust suppression module and control center The center is connected to the signal of the 5G communication module. The dust detection module includes multiple dust sensors evenly installed in the mixing station. The multiple dust sensors are connected to the signal of the GPS positioning module. Corresponding to the positions of multiple dust sensors respectively, the number of nozzles 1 corresponding to each dust sensor is not less than 5, and the multiple nozzles 1 are evenly distributed within a range of 5 meters centered on the dust sensor. When it is detected that the dust content in the air near it exceeds the standard, multiple nozzles 1 near it release water vapor at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com