Preparation method of Al/PVDF microspheres

A technology of microspheres and powders, applied in the field of preparing Al/PVDF microspheres, which can solve the problems of easy agglomeration of samples, complicated operation, long production cycle, etc., and achieve the effect of uniform distribution of components, simple equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

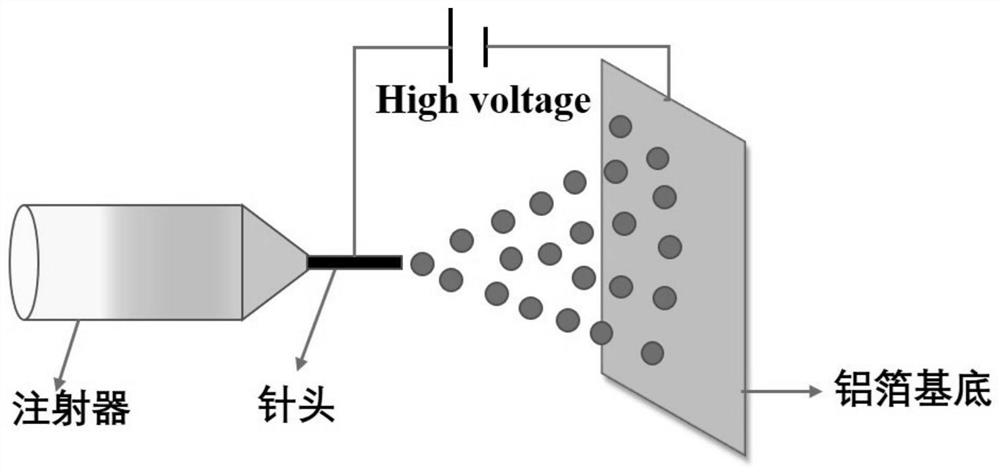

[0025] The present invention is a kind of preparation method of Al / PVDF microsphere, concrete steps are as follows:

[0026] The first step is to weigh an appropriate amount of PVDF, and then dissolve PVDF in an appropriate amount of DMF and acetone mixed solvent, the volume ratio of DMF and acetone is 1:4. Stir ultrasonically to fully dissolve PVDF to obtain a PVDF solution at a stirring speed of 650-800 rpm for 2-5 minutes;

[0027] The second step is to weigh an appropriate amount of nano-aluminum powder, add it to the PVDF solution, first magnetically stir for 5-10 minutes, and then sonicate for 0.5-1h to obtain a nano-aluminum powder PVDF dispersion, and then magnetically stir for 20-24 hours to obtain an electrostatic spray precursor The stirring speed is 650-800 rpm. During the ultrasonic process, the temperature of the water in the ultrasonic instrument should be prevented from being too high. The water should be changed every 5-10 minutes. In winter, the water change ...

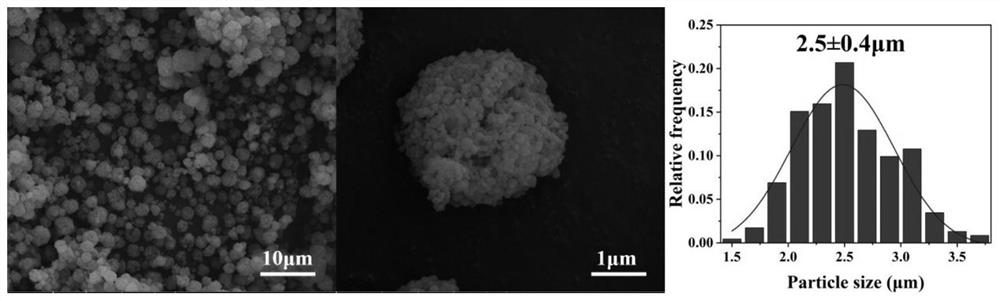

Embodiment 1

[0031] The first step is to weigh 6 mg of PVDF powder, add the powder to 1 mL of DMF: acetone = 1:4 (volume ratio) solvent, place it on a magnetic stirrer at 750 rpm and stir for 2 min, then sonicate to PVDF Completely dissolve to obtain PVDF solution;

[0032] In the second step, 194 mg of nano-aluminum powder (active aluminum content = 82.1%) was weighed, and n-Al was added to the PVDF solution, first placed on a magnetic stirrer at 650 rpm for 5 min, and then ultrasonically dispersed for 1 h. Then place it on a magnetic stirrer at 650 rpm and stir for 24 h to obtain the electrostatic spray precursor;

[0033] The third step is to use a 10 mL syringe to absorb the precursor solution, place it on the bolus of the electrostatic spray, place the aluminum foil base, the distance from the needle to the aluminum foil is 10 cm, connect the power supply, the needle is connected to the positive, the aluminum foil is connected to the negative, and the voltage is 19 (±0.25) kV, open t...

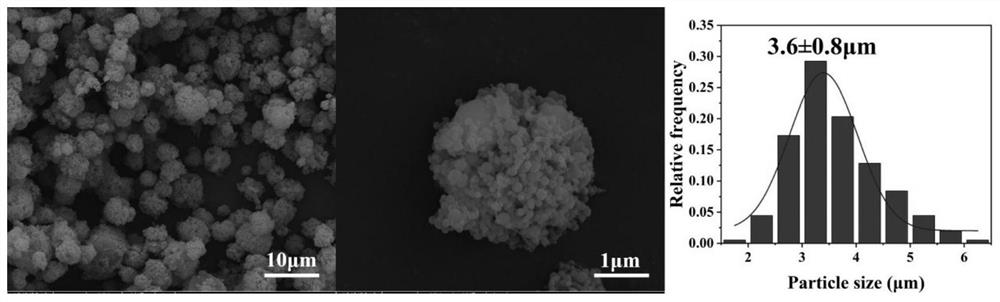

Embodiment 2

[0036] The first step is to weigh 20 mg of PVDF powder, add the powder to 1 mL of DMF: acetone = 1:4 (volume ratio) solvent, place it on a magnetic stirrer at 800 rpm and stir for 2 min, then sonicate until PVDF is completely Dissolve to obtain PVDF solution;

[0037] In the second step, 180 mg of nano-aluminum powder (active aluminum content = 82.1%) was weighed, and n-Al was added to the PVDF solution, first placed on a magnetic stirrer at 650 rpm for 5 min, and then ultrasonically dispersed for 1 h. Then place it on a magnetic stirrer at 650 rpm and stir for 24 h to obtain the electrostatic spray precursor;

[0038] The third step is to use a 10 mL syringe to absorb the precursor solution, place it on the bolus of the electrostatic spray, place the aluminum foil base, the distance from the needle to the aluminum foil is 10 cm, connect the power supply, the needle is connected to the positive, the aluminum foil is connected to the negative, and the voltage is 19 (±0.25) kV,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com