Special automobile polypropylene composite material added with non-woven fabric reclaimed material

A technology of composite materials and non-woven fabrics, which is applied in the field of polypropylene composite material preparation and can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

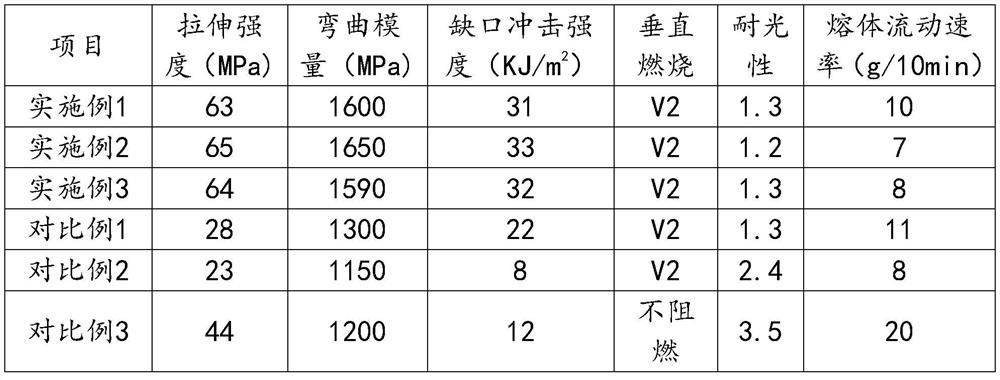

[0033] A polypropylene composite material for automobiles added with non-woven recycled materials, comprising the following raw materials in parts by weight: 30 parts of polypropylene resin, 20 parts of high-impact polypropylene, 10 parts of non-woven regenerated fiber, and 5 parts of modified silica 3 parts, 3 parts of toughening agent and 1 part of antioxidant;

[0034] The automotive-specific polypropylene composite material with non-woven recycled materials is made by the following steps:

[0035] The first step is to add polypropylene resin and high-impact polypropylene to the reactor, raise the temperature to 180°C at a heating rate of 3°C / min, and then stir at a speed of 200r / min for 30min, then add non-woven fabrics to the reactor Regenerated fiber, modified silicon dioxide, toughening agent and antioxidant, increase the rotating speed to 400r / min, after stirring for 30min, a mixture is obtained;

[0036] The second step is to add the mixture obtained in the first ste...

Embodiment 2

[0049] A polypropylene composite material for automobiles added with non-woven recycled materials, comprising the following raw materials in parts by weight: 30 parts of polypropylene resin, 20 parts of high-impact polypropylene, 10 parts of non-woven regenerated fiber, and 5 parts of modified silica 3 parts, 3 parts of toughening agent and 1 part of antioxidant;

[0050] The automotive-specific polypropylene composite material with non-woven recycled materials is made by the following steps:

[0051] The first step is to add polypropylene resin and high-impact polypropylene to the reactor, raise the temperature to 180°C at a heating rate of 3°C / min, and then stir at a speed of 200r / min for 30min, then add non-woven fabrics to the reactor Regenerated fiber, modified silicon dioxide, toughening agent and antioxidant, increase the rotating speed to 400r / min, after stirring for 30min, a mixture is obtained;

[0052] The second step is to add the mixture obtained in the first ste...

Embodiment 3

[0065] A polypropylene composite material for automobiles added with non-woven recycled materials, comprising the following raw materials in parts by weight: 30 parts of polypropylene resin, 20 parts of high-impact polypropylene, 10 parts of non-woven regenerated fiber, and 5 parts of modified silica 3 parts, 3 parts of toughening agent and 1 part of antioxidant;

[0066] The automotive-specific polypropylene composite material with non-woven recycled materials is made by the following steps:

[0067] The first step is to add polypropylene resin and high-impact polypropylene to the reactor, raise the temperature to 180°C at a heating rate of 3°C / min, and then stir at a speed of 200r / min for 30min, then add non-woven fabrics to the reactor Regenerated fiber, modified silicon dioxide, toughening agent and antioxidant, increase the rotating speed to 400r / min, after stirring for 30min, a mixture is obtained;

[0068] The second step is to add the mixture obtained in the first step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com