Graphene reinforced rare earth magnesium-based composite material and preparation method thereof

A composite material, rare earth magnesium technology, applied in the field of graphene reinforced rare earth magnesium matrix composite material and its preparation, to achieve the effects of strength and plasticity improvement, wettability improvement, strength and plasticity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a method for preparing a graphene-reinforced rare-earth magnesium-based composite material, comprising the following steps:

[0019] Step 1. Preparation of rare earth magnesium alloy semi-solid slurry: Raise the temperature of rare earth magnesium alloy to 700°C-800°C, and reduce the temperature to 550°C-650°C after the rare earth magnesium alloy matrix is completely melted to obtain rare earth magnesium alloy semi-solid slurry ;

[0020] In this step, the composition of the rare earth magnesium alloy is Mg-(0-20)X-(0-1)Zr-(0-10)Ag(wt.%), X is Gd, La, Er, Y, One or a combination of Sc and Zn. Rare earths can refine the grains of magnesium alloys, reduce the tendency of thermal cracking, and improve the comprehensive strength and toughness of the alloy at room temperature and high temperature. Silver plays a solid solution strengthening role in rare earth magnesium alloys, which can improve the plasticity of rare earth magnesium alloys.

[0021...

Embodiment 1

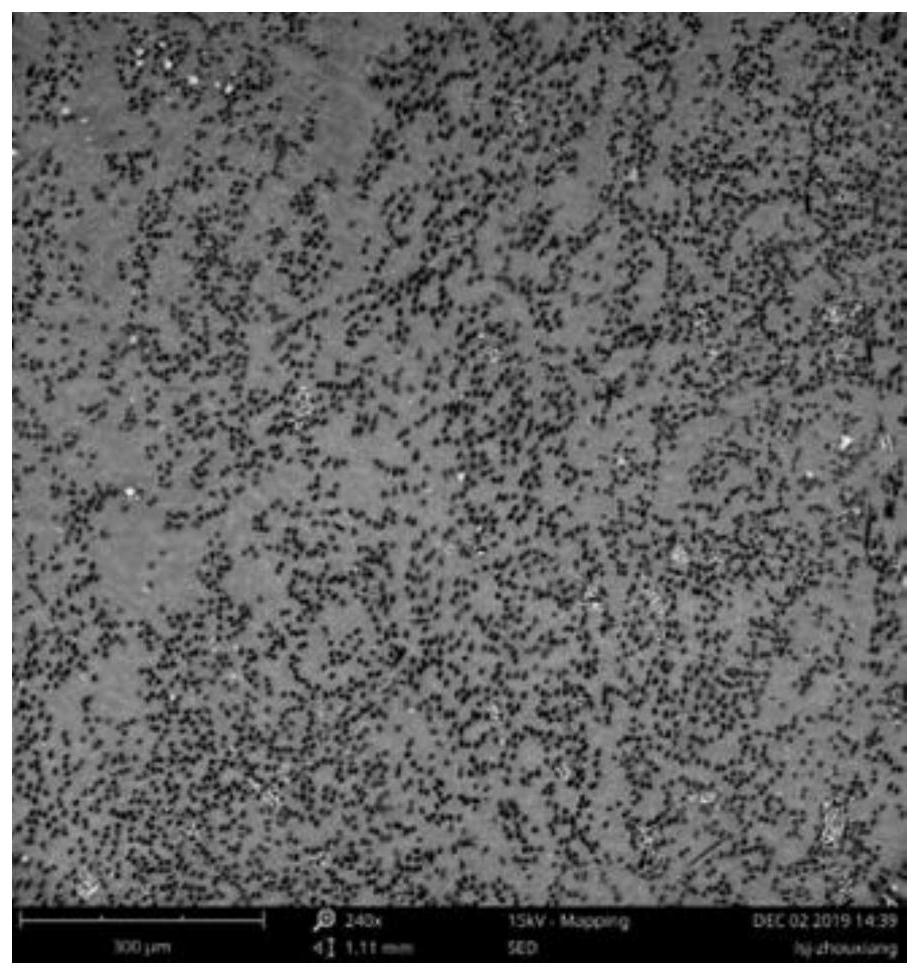

[0030] Heat 8 kg of the matrix Mg-7Gd-0.5Zn-0.4Zr-2Ag rare earth magnesium alloy to 750°C to melt, then cool down to 610°C, and keep it warm for 5 minutes to obtain a rare earth magnesium alloy semi-solid slurry. Then add 1.1kg of silver-coated graphene (silver content is 65wt%, the rest is graphene, the particle size is 20 μm), carry out ultrasonic stirring, the power is 800KW, the time is 35min. Raise the temperature to 730°C again, and perform ultrasound with a power of 600KW for 10 minutes. Then it is poured into a mold preheated to 300°C and solidified under a pressure of 25MPa to obtain a graphene-enhanced rare earth magnesium-based composite material with a graphene content of 4.2wt% and a silver content of 9.6wt%. The SEM image of the composite material is as follows figure 1 shown.

[0031] After testing, the room temperature tensile strength of the composite material is 396MPa, and the elongation is 6.7%.

Embodiment 2

[0033] Heat 10kg of the matrix Mg-8Gd-2Y-5Ag rare earth magnesium alloy to 760°C to melt, then cool down to 580°C, and keep it warm for 8 minutes to obtain a rare earth magnesium alloy semi-solid slurry. Then add 0.8kg silver-coated graphene (silver content is 60wt%, the rest is graphene, particle size is 15 μ m), carry out mechanical stirring, rotating speed 900r / min, time 25min. Raise the temperature to 740°C again, and perform ultrasound with a power of 600KW for 8 minutes. Then it is poured into a mold preheated to 200° C. and solidified under a pressure of 10 MPa to obtain a graphene-reinforced rare-earth magnesium-based composite material with a graphene content of 3 wt % and a silver content of 9 wt %.

[0034] After testing, the room temperature tensile strength of the composite material is 412MPa, and the elongation is 7.3%.

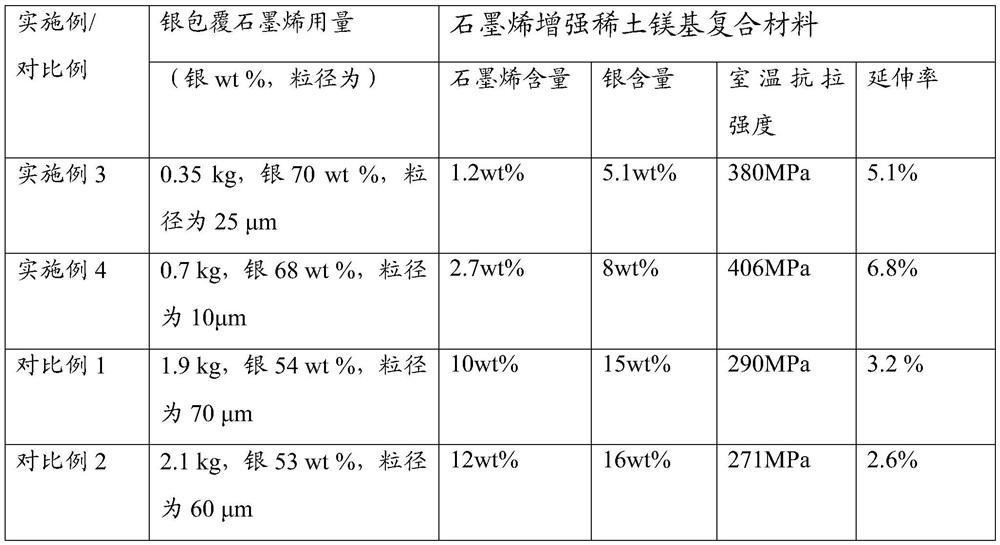

[0035] Example 3 ~4 and comparative examples 1~2

[0036] Examples 3-4 and Comparative Examples 1-2 are the same as Example 1, except that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com