Fluid module, fluid system and method of cleaning fluid module

A technology of fluid modules and fluid chambers, which is applied in the direction of liquid cleaning methods, chemical instruments and methods, biochemical equipment and methods, etc., which can solve the problems of pollution in the transmission medium area, high pollution, and unusable cell cultures, etc., to achieve Effect of compact structure and simplified fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

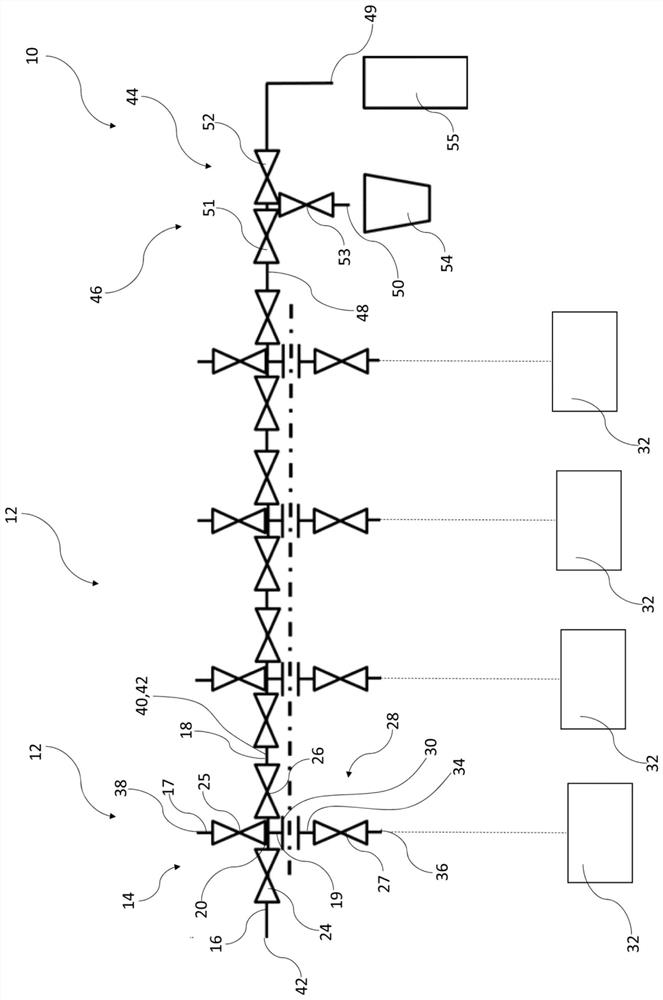

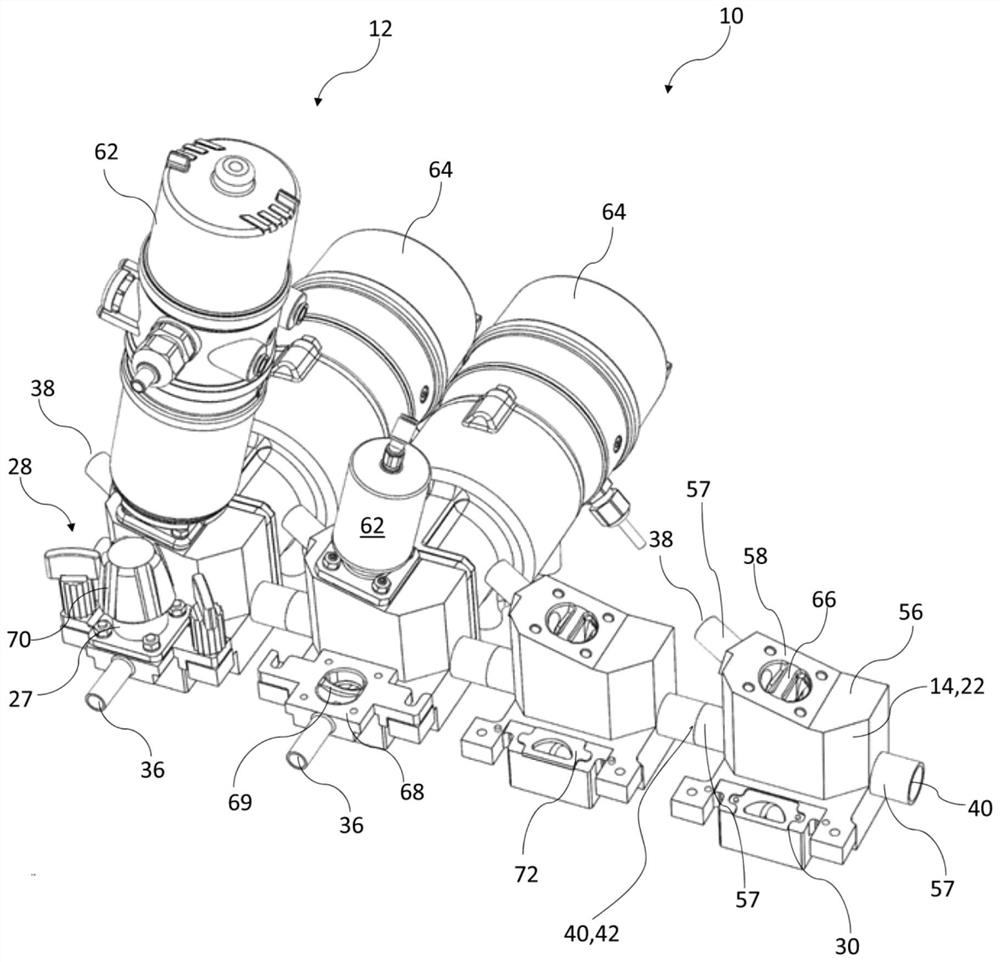

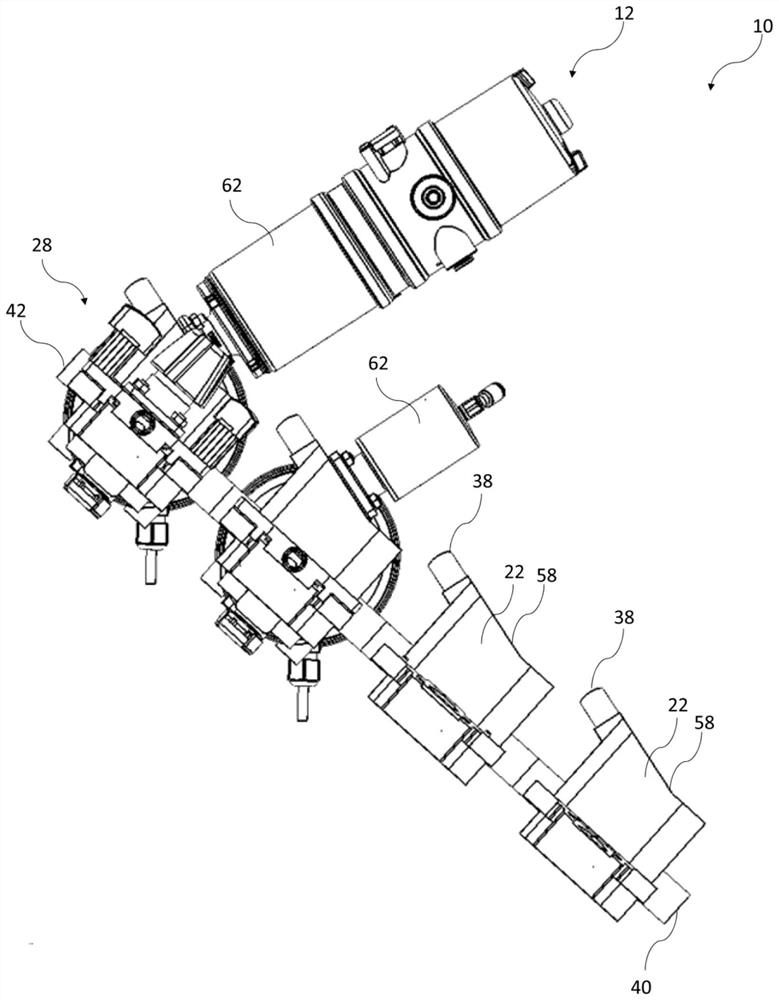

[0058] figure 1 A fluid system 10 according to the invention is shown schematically, which has a plurality of fluid modules 12 according to the invention. The individual fluid modules 12 are fluidically connected to one another.

[0059] Each fluid module 12 comprises a valve node 14 which has four flow-spaced fluid channels 16 , 17 , 18 , 19 which open into a central fluid chamber 20 .

[0060] The fluid channels 16, 17, 18, 19 and the central fluid chamber 20 are constructed in a base body 22, which is in figure 2 can be seen in .

[0061] The fluid module 12 also includes four individual valves 24 , 25 , 26 , 27 which serve to block or release the fluid flow through the assigned fluid channels 16 , 17 , 18 , 19 .

[0062] One of the individual valves 24 , 25 , 26 , 27 is part of a connection module 28 which is fastened at a connection point 30 on the valve node 14 . The corresponding individual valve 27 thus forms a connecting valve. The isolation between the valve no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com