Thermochemical heat storage system and method

A heat storage system and thermochemical technology, applied in the field of thermochemical heat storage system and heat storage, can solve the problems of waste of solar energy resources, waste of solar energy resources, and environmental hazards, etc., to reduce light abandonment, improve utilization rate, and improve energy storage The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

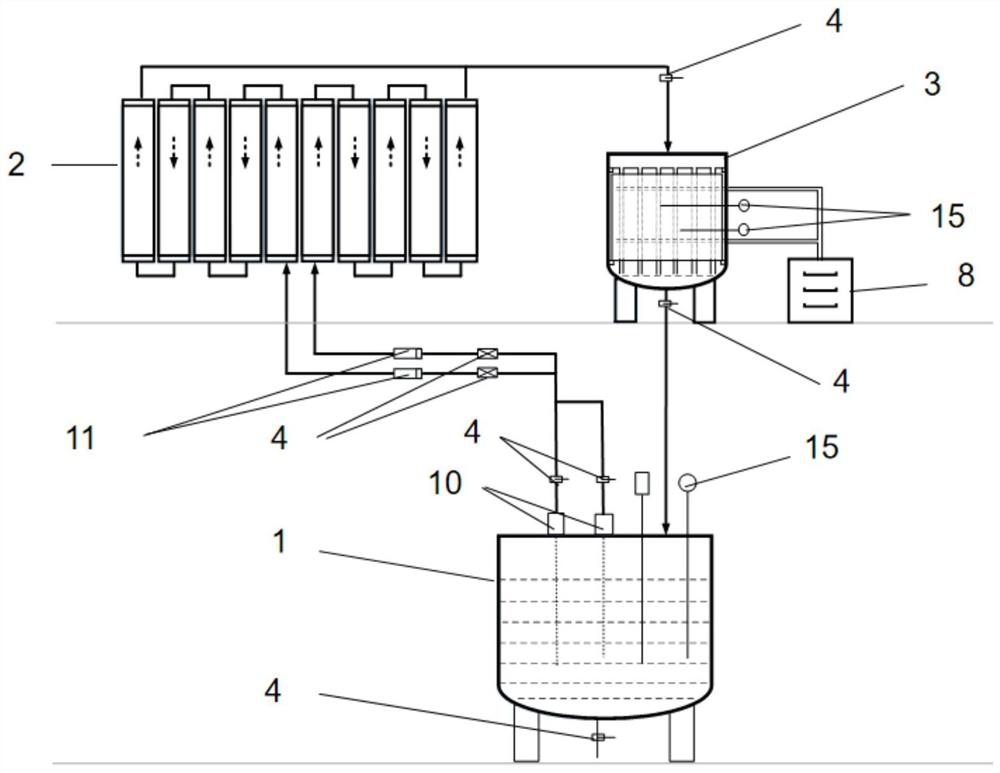

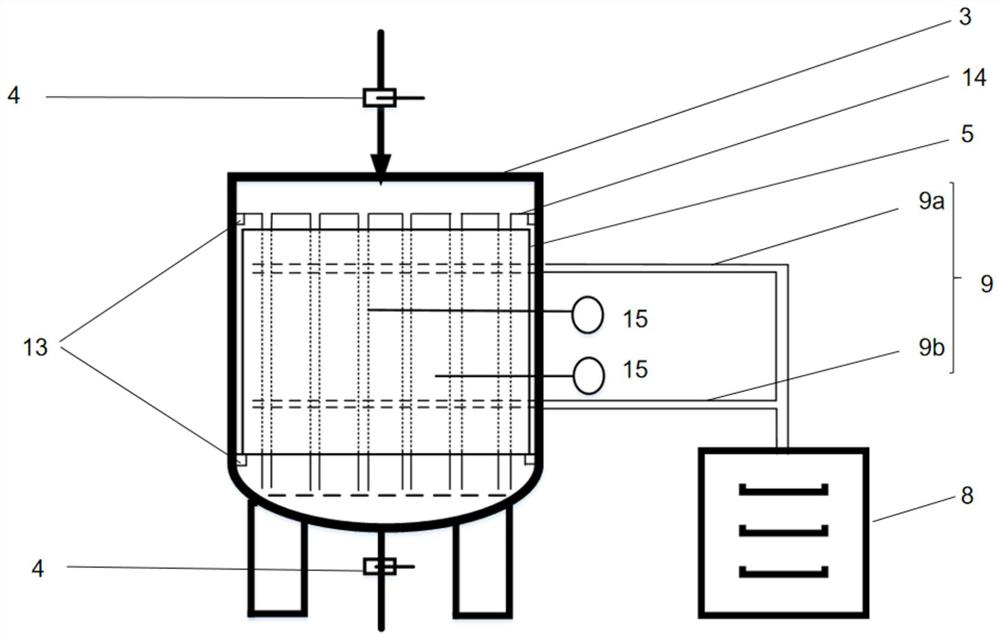

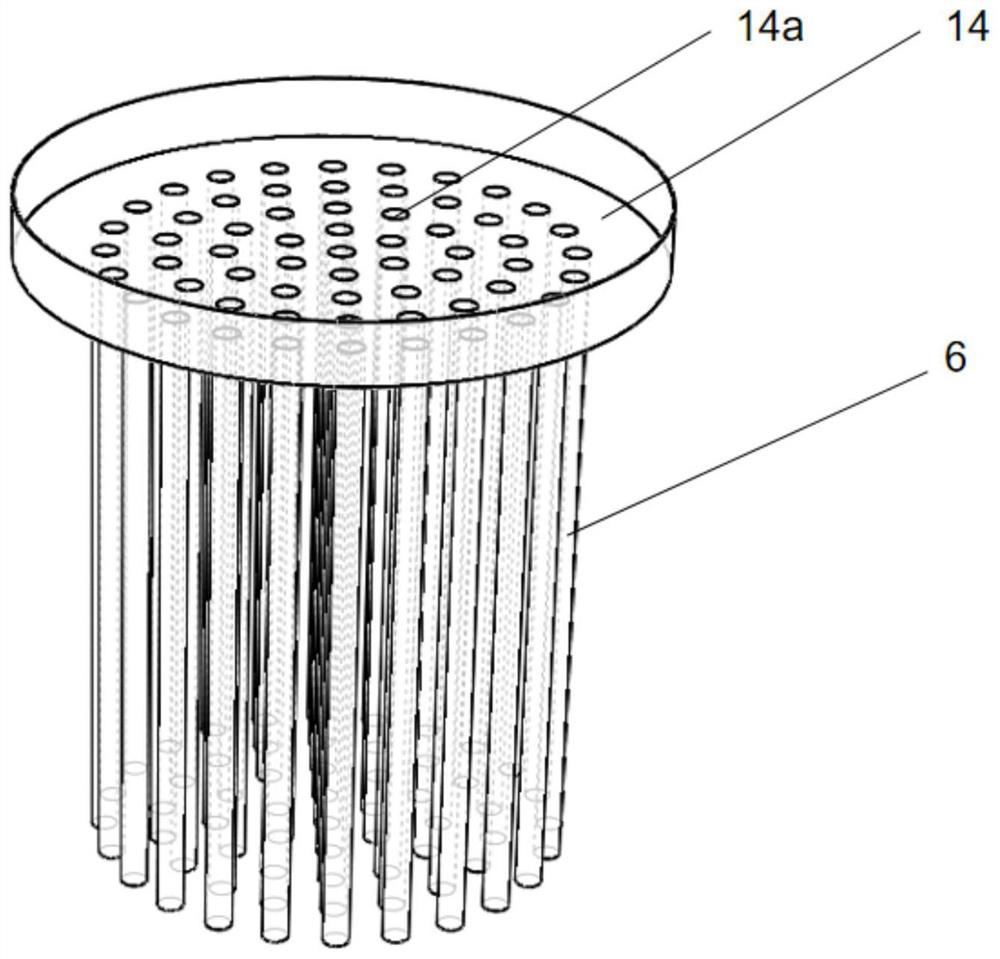

[0059] The first embodiment of the present invention provides a thermochemical heat storage system, see figure 1 and figure 2 As shown, it includes a low-temperature molten salt storage tank 1, a heat absorber 2, and a thermochemical molten salt storage tank 3 connected in sequence to form a circulation loop. Both the inlet and the outlet of the tank 3 are provided with valves 4 . The outlet of the low-temperature molten salt storage tank 1 communicates with the inlet of the heat absorber 2, the outlet of the heat absorber 2 communicates with the inlet of the thermochemical molten salt storage tank 3, and the outlet of the thermochemical molten salt storage tank 3 communicates with the low-temperature molten salt storage tank The entrance of 1 is connected. The exterior of the low-temperature molten salt storage tank 1 and / or the thermochemical molten salt storage tank 3 is wrapped with an insulating material (not shown) to reduce external heat dissipation of the low-temper...

Embodiment approach 2

[0085] The second embodiment of the present invention provides a thermochemical heat storage system. The second embodiment is a further improvement on the first embodiment. Parts not specifically described include reference numerals and text descriptions, which are the same as those of the first embodiment. The method is the same and will not be repeated here.

[0086] The main improvement of the second embodiment over the first embodiment is that in the second embodiment of the present invention, the combination Figure 6 From the point of view, the thermochemical heat storage system also includes a high-temperature molten salt storage tank 16. The inlet and outlet of the high-temperature molten salt storage tank 16 are connected with the outlet of the heat absorber 2 and the inlet of the low-temperature molten salt storage tank 1 respectively. The inlet and outlet of the storage tank 16 are also provided with valves 4 , and the high-temperature molten salt storage tank 16 an...

Embodiment approach 3

[0103] The third embodiment of the present invention provides a thermochemical heat storage system. The third embodiment is a further improvement on the second embodiment. Parts not specifically described include reference numerals and text descriptions, which are the same as those of the second embodiment. The method is the same and will not be repeated here.

[0104] The main improvement of the third embodiment over the second embodiment is that in the third embodiment of the present invention, the combination of Figure 8 From the point of view, the material of the thermochemical heat storage module is CaCO 3 / CaO or MgCO 3 / MgO, CaCO 3 / CaO or MgCO 3 / MgO can spontaneously decompose at high temperature to generate CaO and MgO, and absorb CO 2 And absorb a lot of heat, CaO and MgO can add CO 2 Afterwards, the recombination reaction occurs spontaneously to form CaCO 3 and MgCO 3 And release a lot of heat. The aforementioned evaporator 8 is replaced by CO 2 The stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com