High-thermal-conductivity silicon carbide device packaging structure and method

A device packaging, high thermal conductivity technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as the stability of the unfavorable silicon carbide device structure, normal use, and increased heat generation. , to achieve good cooling effect and reduce conduction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

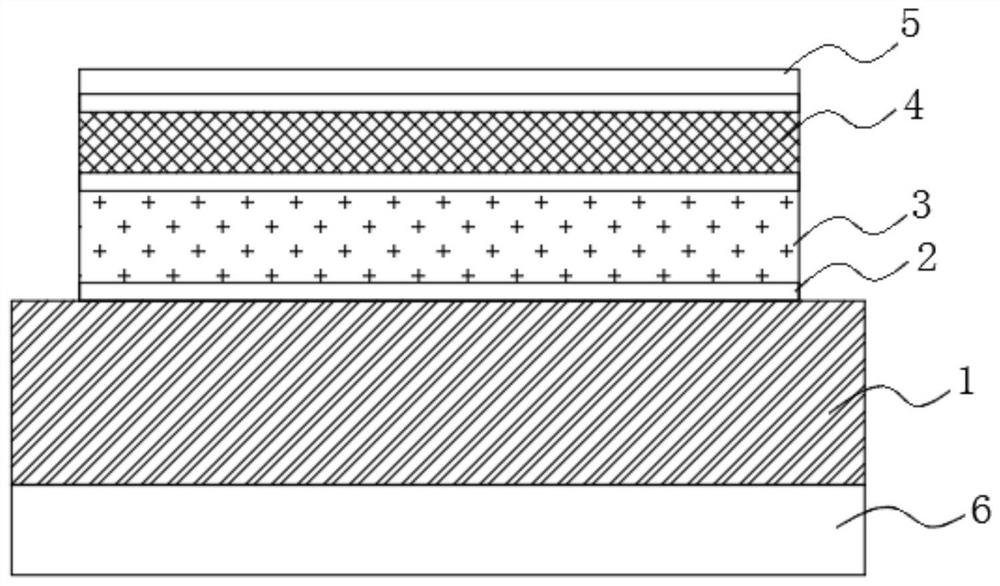

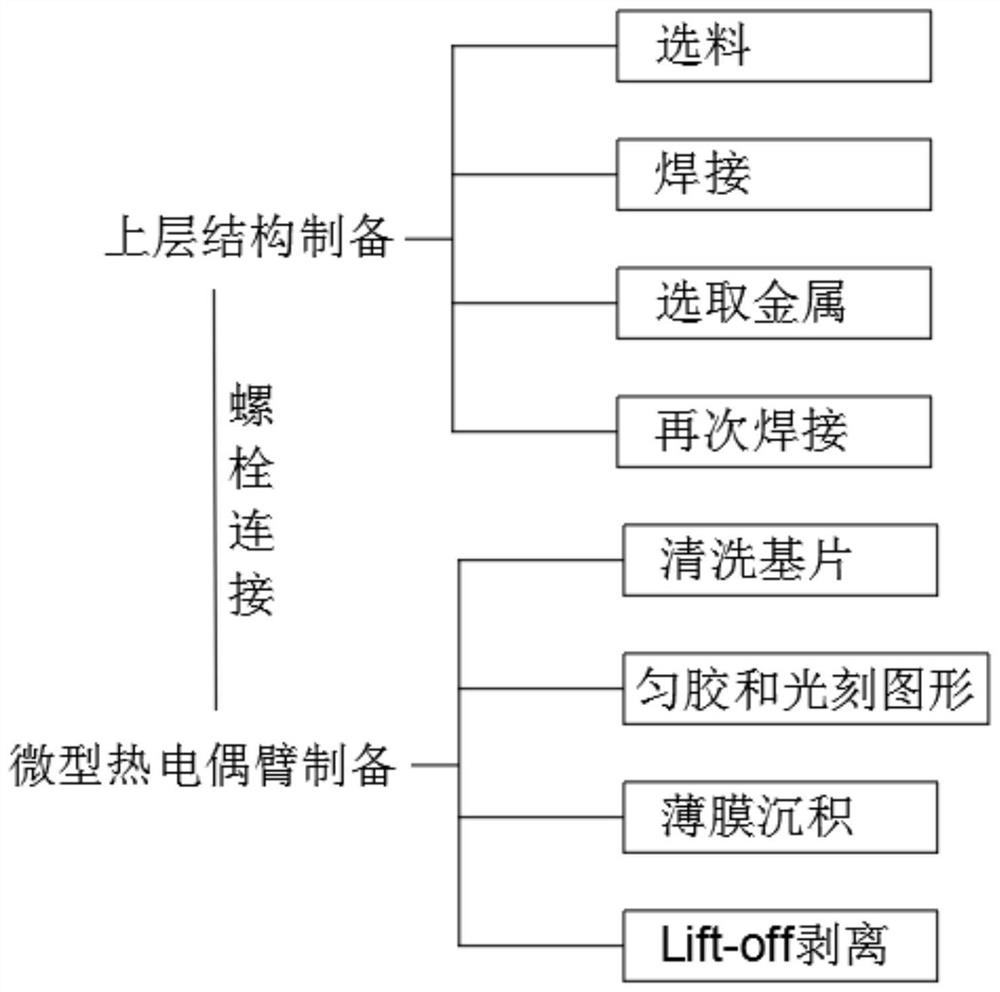

[0025] Embodiment one, by Figure 1-2 Provided, the present invention provides a high thermal conductivity silicon carbide device packaging structure and method, including a heat sink 1, an adhesive layer 2, a metal layer 3, an insulating substrate 4, a circuit layer 5 and a miniature thermocouple arm 6, the thermal The surface of the sink 1 is connected to the metal layer 3 through the bonding layer 2, the surface of the metal layer 3 is connected to the insulating substrate 4 through the bonding layer 2, the surface of the insulating substrate 4 is connected to the circuit layer 5 through the bonding layer 2, and the heat sink 1 A miniature thermocouple arm 6 is mounted on the bottom end of the bottom end by bolts.

[0026] The insulating substrate 4 is one or more of aluminum nitride ceramic materials, alumina ceramic materials or silicon carbide ceramic materials.

[0027] The bonding layer 2 adopts active metal brazing material.

[0028] A high thermal conductivity sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com