A hub motor with built-in torque sensor

A torque sensor and in-wheel motor technology, applied in motor vehicles, electric components, power management, etc., can solve problems such as reducing the unsprung mass of the vehicle, lack of heat dissipation structure inside the motor, and affecting riding safety

Active Publication Date: 2022-05-31

江苏晨朗电子集团有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The overall structure of the present invention forms a box-shaped or semi-box-shaped structure, and the stator shell and the rotor shell are provided with a rib structure, which has the characteristics of high strength, high rigidity, and light weight, and greatly reduces the overall vehicle weight while meeting the strength and stiffness of the hub motor. Unsprung quality, low cost, high reliability and redundancy, good heat dissipation and sealing, strong anti-vibration and shock resistance, good motor unit performance, improved power density, and adapt to the high demands of electric vehicles and large special electric vehicles High power and high torque requirements", the in-wheel motor adopts a circulating water cooling structure to cool down and dissipate heat, but water penetration accidents are prone to occur, which affects the normal operation of the motor;

[0006] 3. The comparative document CN210142953U discloses a heat-insulated hub motor and a vehicle equipped with the heat-insulated hub motor, "comprising: a brake device, a heat shield and a hub motor; the heat shield is arranged between the brake device and the hub motor between, and the heat shield is fixedly connected with the brake device and the hub motor respectively; a gap is provided between the brake device and the heat shield; the heat shield is suitable for blocking the heat generated by the brake device The heat is transferred to the hub motor to prevent the demagnetization of the hub motor due to the heat generated by the brake, which prevents the heat from being transferred to the inside of the motor through the heat shield when it is used, but it fails to realize the internal heat of the motor. The transfer to the outside leads to the lack of a corresponding heat dissipation structure for the internal heat of the motor, which affects the safety of the motor and cannot guarantee the normal operation of the motor;

The brake ring and the motor body are integrated to reduce the influence of external factors, there is no abnormal sound, the structure is simple, the cost is low, and the installation and replacement of the brake device are more convenient." However, this device lacks corresponding functions when braking. The signal reminder device of the vehicle body with the hub motor is prone to speeding and extreme braking accidents when driving on a downhill section, which affects riding safety

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0040] Below in conjunction with the accompanying drawings in the embodiments of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely

[0061] It will be apparent to those skilled in the art that the invention is not limited to the details of the above-described exemplary embodiments, but also

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

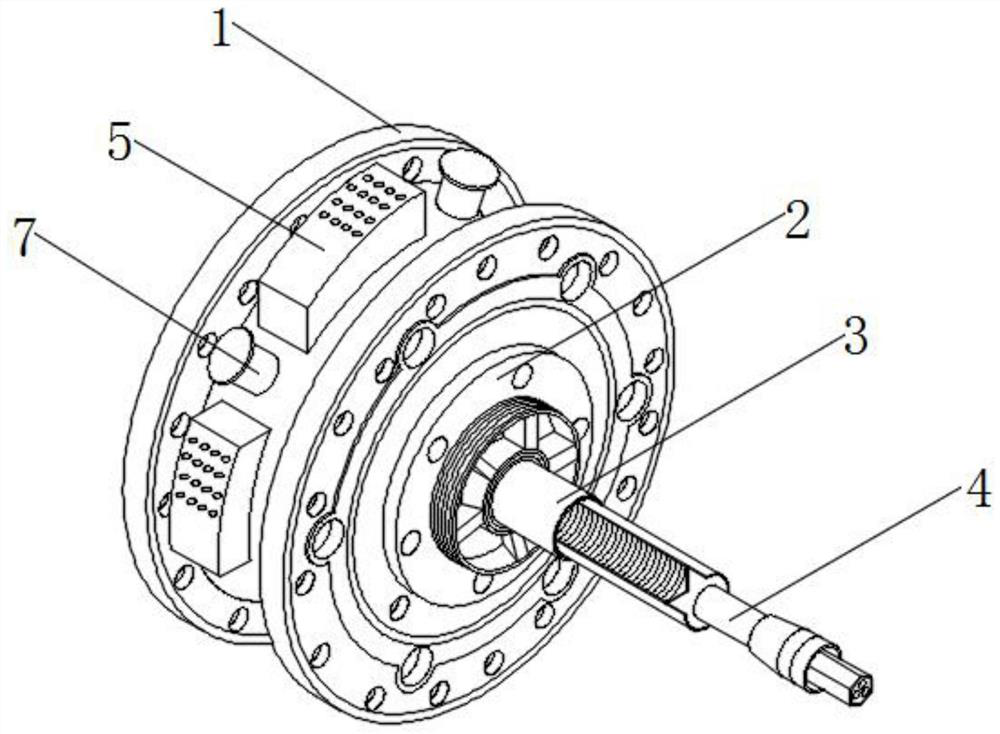

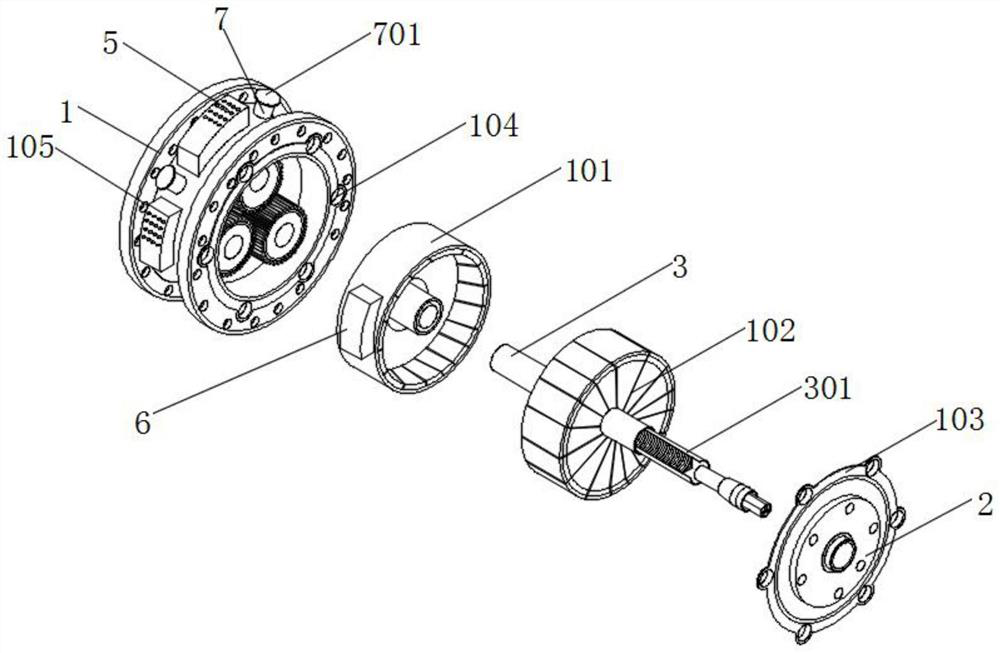

Login to View More Abstract

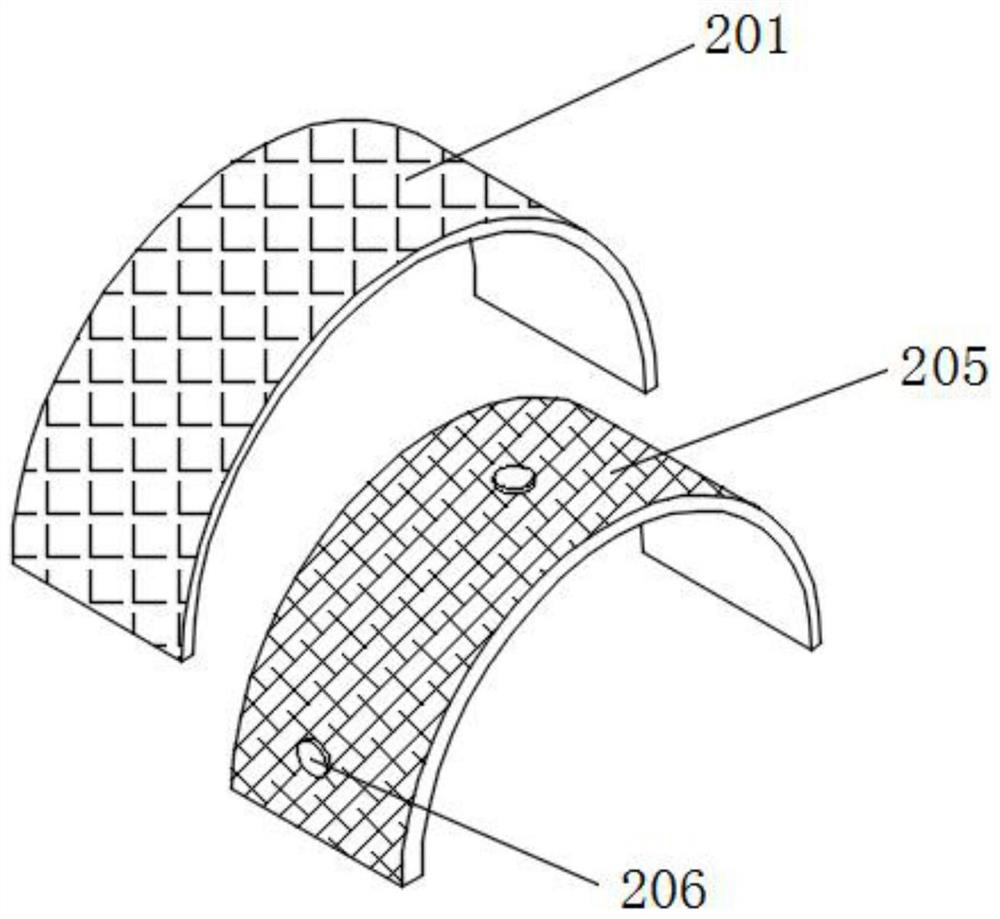

The invention discloses an in-wheel motor with a built-in torque sensor, which comprises a motor body and a torque sensing box. A front panel of an end cover is installed on the front of the motor body, and a torque sensing box is installed on the front of the front panel of the end cover. A transmission rod is installed inside the extrusion runner, a heat dissipation explosion-proof box is installed on the surface of the motor body, a sealed heat insulation module is installed on the front of the transmission rod, and two groups of symmetrical Arranged winding posts, two sets of symmetrically arranged correction boxes are installed on the surface of the rotor assembly. The present invention installs the torque sensing box, the deformed force block, the deformed resistance block, the No. 1 pressure sensor and the No. 2 pressure sensor, when the bicycle is started from a static state or encounters resistance during riding, the instant and dynamic The combination of detection, according to the rider's pedaling force, continuously adjusts and controls the power output of the motor, thereby assisting the rider to ride more effortlessly.

Description

An in-wheel motor with built-in torque sensor technical field [0001] The present invention relates to the technical field of electromagnetic deceleration motors, in particular to a hub motor with a built-in torque sensor. Background technique With the development of intelligent travel, electric power-assisted bicycles are more and more favored by people. The organic combination of pedal and motor assist, the industry is generally beginning to pay attention to the combination of torque sensor and motor control system, The present invention provides a new way for the torque sensor and motor control system—the wheel hub motor with built-in torque sensor machine. The defect that existing in-wheel motor exists is: 1, the contrast document CN207082972U discloses a kind of in-wheel motor and in-wheel motor system, "this in-wheel motor package including a fixed seat, a driving wheel and an encoding module; the driving wheel is connected with the fixed seat through the ax...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02K11/20H02K11/215H02K9/04H02K5/10H02K7/00H02K9/22H02K11/30B62M6/50B62M6/45B62M6/40B62M7/12

CPCH02K11/20H02K11/215H02K9/04H02K5/10H02K7/006H02K9/22H02K11/30B62M6/50B62M6/45B62M6/40B62M7/12Y02T10/72

Inventor 陈栋榑林文雄蔡宪文胡明李猛

Owner 江苏晨朗电子集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com