Irradiation protection method for space electronic equipment

An electronic equipment and irradiation technology, which is applied in the field of aerospace, can solve problems such as short-circuit faults of electronic equipment, increase in the weight of aerospace instruments, and potential safety hazards in the combination strength of shielding protection devices and devices, so as to improve the ability to resist total dose and simplify installation Convenience and the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

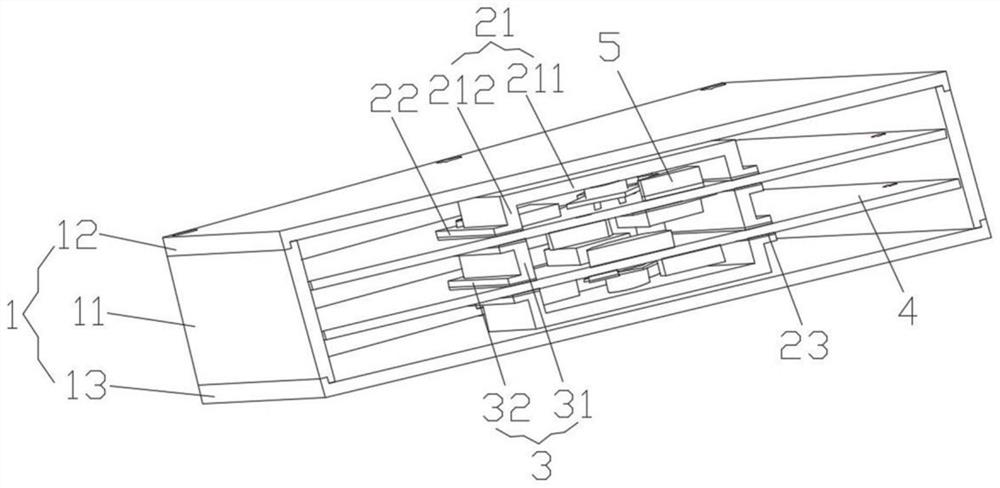

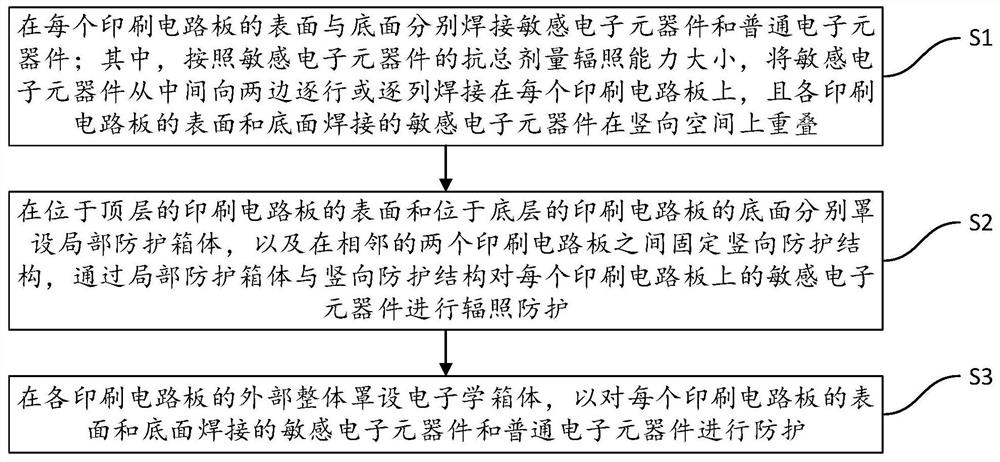

[0030] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. In the following description, the same blocks are denoted by the same reference numerals. With the same reference numerals, their names and functions are also the same. Therefore, its detailed description will not be repeated.

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

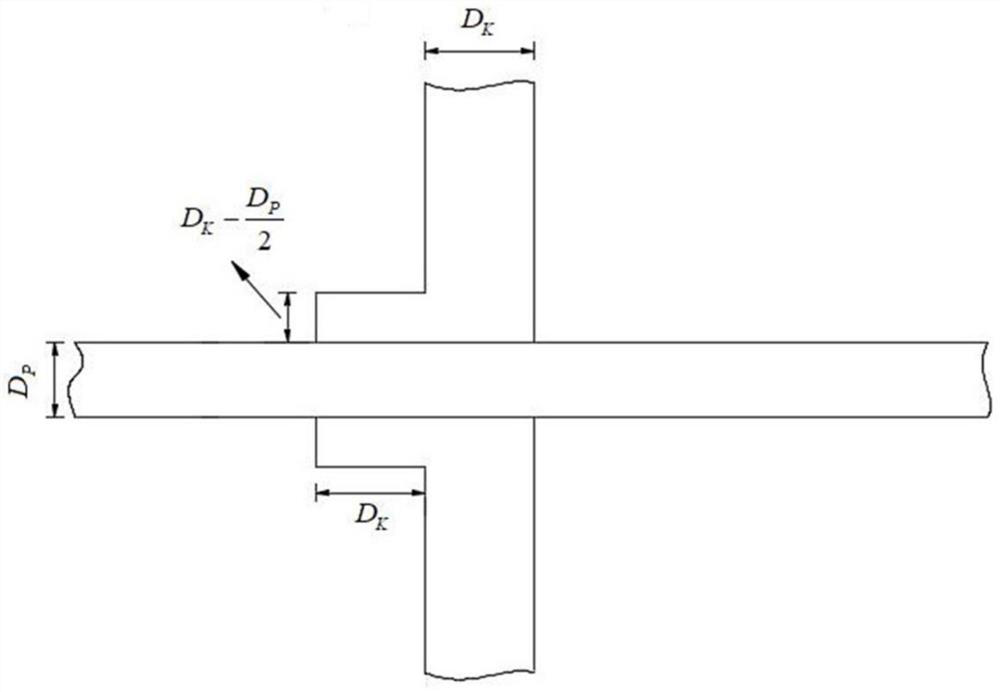

[0032] In the prior art, there are two ways to increase the equivalent aluminum shielding thickness. One is to take all the printed circuit boards as a whole, and set up an electronic box on the outside, and increase the overall thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com